Aluminum Heatsink Extrusion Profiles - Alloy 6063 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

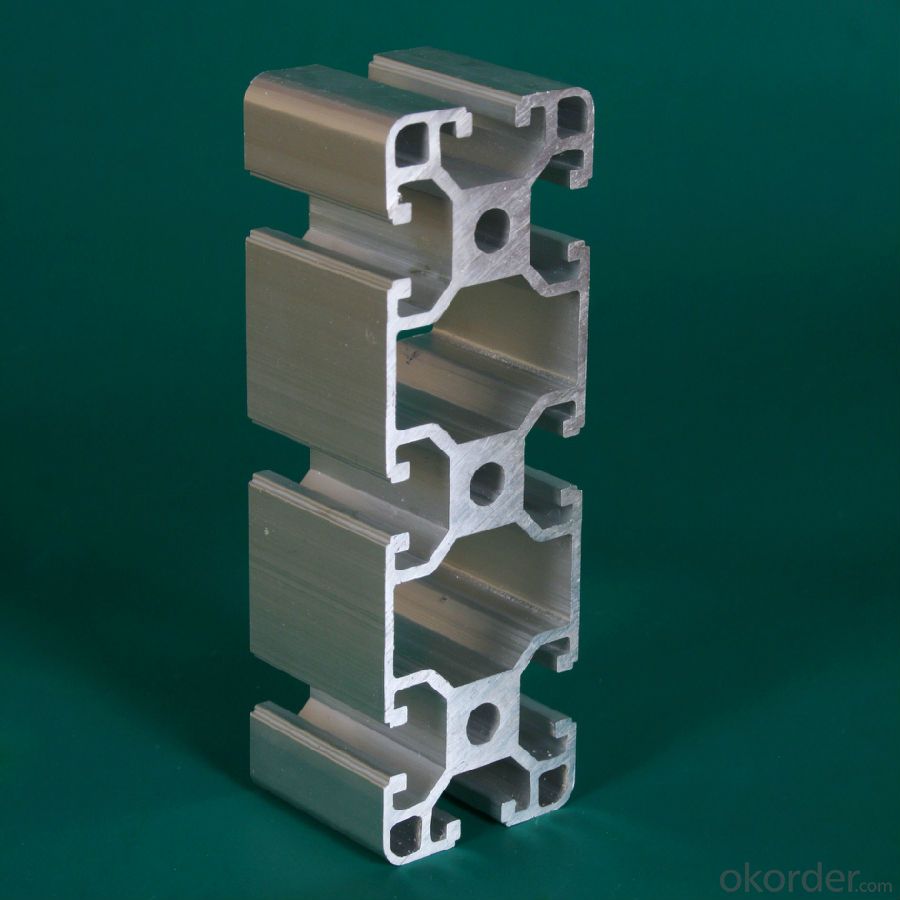

Product Name | Alloy 6063 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: How much is the 5000 ton aluminum profile extrusion machine? What section can I have?

- 5000 tons press, plus auxiliary machine, installed finished, almost 50 million -1 million, this depends on the configuration. Cheap certainly also domestic, but a penny a cent goods.A general can reach the maximum about 400mm.

- Q: How do you prevent warping or distortion of aluminum profiles during fabrication?

- In order to prevent warping or distortion of aluminum profiles during fabrication, there are several key measures that can be implemented: 1. Storage in a controlled environment is crucial prior to fabrication. It is essential to store the aluminum profiles in an environment with stable temperature and humidity levels. This will help minimize any potential changes in the shape or dimensions of the metal. 2. Proper handling techniques must be employed to avoid bending or twisting the aluminum profiles. This includes using appropriate lifting equipment, avoiding excessive force, and ensuring even support during transportation. 3. During the fabrication process, it is important to utilize suitable machining techniques that minimize heat buildup. Excessive heat can cause the aluminum to expand and potentially warp. Utilizing cooling techniques such as lubricants or coolants can disperse heat and prevent distortion. 4. Controlled welding is crucial when working with aluminum profiles. Maintaining proper control over the welding process is essential. Employing appropriate welding techniques, such as preheating and post-weld heat treatment, can help minimize distortion. 5. Adequate fixturing methods should be employed during fabrication to ensure that the aluminum profiles are held in the correct position throughout the process. This prevents unintended bending or warping that could occur due to improper support or clamping. 6. Stress-relieving processes can be implemented after fabrication to minimize residual stresses within the aluminum profiles. This will prevent distortion or warping that may occur during subsequent handling or usage. 7. Regular inspection and measurement of the aluminum profiles during fabrication is necessary to identify any deviations from the desired specifications. This enables prompt corrective actions to be taken, reducing the risk of warping or distortion. By implementing these steps, manufacturers can significantly decrease the likelihood of warping or distortion in aluminum profiles during fabrication, ensuring the production of high-quality components or products.

- Q: 6063 aluminum manufacturers fail to notice how to write a written report

- Ask if your manufacturer has a template. How do you write it?In fact, this is not what the provisions of how to write, as long as the two agreed to make things clear, double admit something on the line, cover double seal, all right, hope to be able to help you, thank you for the adoption.

- Q: Are aluminum profiles suitable for noise barriers?

- Indeed, noise barriers can be effectively constructed using aluminum profiles. The durability, corrosion resistance, and lightweight nature of aluminum make it an ideal material for noise barriers. By either absorbing or reflecting sound waves, aluminum profiles can effectively diminish noise pollution. Moreover, the malleability of aluminum offers numerous design possibilities, rendering it highly adaptable for diverse noise barrier applications. Additionally, aluminum is an environmentally conscious choice as it is both recyclable and sustainable. In summary, aluminum profiles are a viable choice for noise barriers owing to their enduring nature, efficacy in noise reduction, and design flexibility.

- Q: Is it possible to recycle aluminum profiles repeatedly without a substantial loss in their quality or functionality?

- <p>Yes, aluminum profiles can be recycled multiple times without significant degradation in performance. Aluminum is highly recyclable, and the recycling process does not compromise its properties. In fact, recycled aluminum maintains the same strength, durability, and malleability as new aluminum. This makes it an environmentally friendly material, as it reduces the need for mining new aluminum and conserves resources.</p>

- Q: and I know the meaning of 125MN is 12500 tons. I want to know if 125MN is a English an abbreviation of the word, if it is, then what is he, if he is not that what is the meaning?

- MN is an international unit, said the bull"125MN's extruder is 12500T's extruderBloomberg metal Forum

- Q: What is the relationship between aluminum alloy and aluminum alloy?

- First, according to use can be divided into the following categories: 1. building doors and windows, aluminum doors and windows [1] (divided into two windows and curtain walls). Special aluminum radiator 2. CPU radiator 3. Aluminum Alloy shelf aluminum profile, the difference between them is that the different cross-sectional shapes. They are produced by hot melt extrusion 4.. Industrial aluminum: mainly used in automation equipment, sealing cover skeleton and the custom mold machinery and equipment according to their own requirements, such as assembly line conveyor belt, hoisting machine, glue machine, testing equipment, electronic machinery industry and clean room with the majority!

- Q: How do aluminum profiles perform in terms of sound transmission loss?

- Aluminum profiles have gained a reputation for their outstanding ability to reduce sound transmission. This is due to their dense and rigid composition, which effectively impedes and diminishes the propagation of sound waves. The inherent characteristics of aluminum, including its high density and minimal resonance, make it an optimal material for sound insulation purposes. Moreover, the flexibility to customize aluminum profiles with different shapes and thicknesses allows for even greater enhancement of their soundproofing capabilities. Consequently, aluminum profiles are highly sought after for situations where noise reduction is a priority, such as in the construction of buildings, automotive manufacturing, and HVAC systems.

- Q: Does the profiled bar include aluminum profiles? What are the differences between aluminum and profile?

- In fact, profile and profile now in concept, there is not much difference. Special non conventional means. In fact, the conventional shape shape materials generally have a special name: like bar, sheet, pipe, wire rod, angle, elliptical material and so on. So that the profile is actually refers to the profile.

- Q: or what is the difference between the national standard aluminum profile and the European standard aluminum profile, preferably with pictures? Thank you

- The difference between national standard aluminum profile and European standard aluminum profile:Cross section four angles are different: national standard, four angles are right angle, European standard four angles have radian;The shape of the groove is not the same: GB groove is square, European standard slot is obtrapezoid;The rice is different in weight: the national standard is relatively heavy, and the European standard is relatively light.The fittings and installation methods used are different.

Send your message to us

Aluminum Heatsink Extrusion Profiles - Alloy 6063 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords