Aluminum Window Extrusion Profiles - Alloy 6082 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Product Description

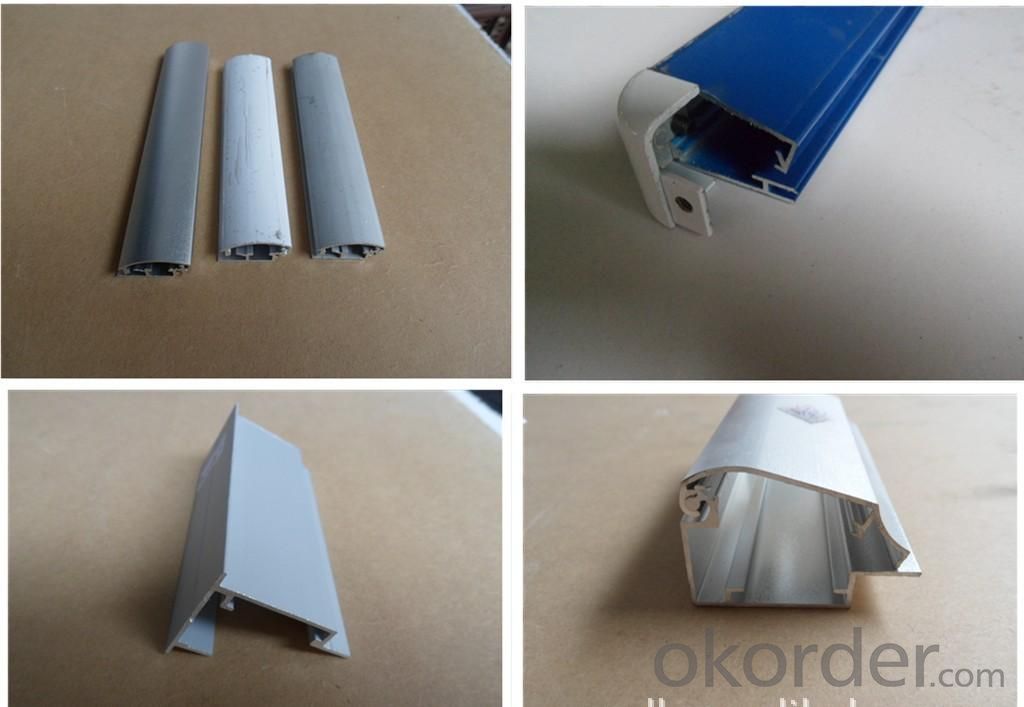

Product Name | Alloy 6082 Aluminium Extrusion Profiles For Industrial Application |

Alloy | Al 6063 T5 /T6 or 6061 T4/T6 or as customers' need |

Surface | Aluminum profiles of mill finish, powder coating, anodizing, polishing, sand blasting, electrophoresis and wood color. |

Profile shape | According to drawings or re-design as requested or market needs. |

Price | Based on Aluminum Ingot Price + Process fee |

Payment term | T/C T/T 30% deposit and 70% pay against copy of B/L |

Certificate | ISO9001 ISO14001 |

Warranty | 1. GB5237-2008 equal to EN12020-1.2(2001); 2. Within 15 years without powder peeling off; |

Product Advantages

1. Plenty of surface treatments for your choice, for example oxidation, electrophoresis and static powder coating, etc.

2. Strict control for surface finish, very little scratch.

3. Accurate mold as well as accurate size.

4. Standard alloy composition

5. Both ends of the profiles are very plain and with no burr.

FAQ

1. What is your main product?

We can supply the aluminium complete system, including aluminum billets, aluminum profile for windows and doors, aluminum for curtain wall, alumimun framwork, and kinds of aluminum windows and doors.

2. What’s your price?

The price is based on buyer's specific requirement, so please provide below information to help us quote exact price to you.

3. What is your payment term?

30% - 50% down payment, the balance payment against, and L/C is available.

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, there are several methods you can use depending on the desired outcome and the tools you have available. Here are three common techniques: 1. Cutting with a hacksaw or miter saw: This is the most basic and accessible method. Using a hacksaw or a miter saw with an aluminum cutting blade, mark the desired length on the profile and carefully cut through it. Ensure you have a secure grip on the profile and make slow, steady cuts to avoid excessive vibration or the blade getting stuck. 2. Using a power saw or circular saw: For larger or thicker aluminum profiles, a power saw or circular saw with a specialized aluminum cutting blade will make the job faster and easier. Measure and mark the desired length on the profile, then secure it firmly in place. Using the power saw, slowly and steadily cut through the profile, ensuring you have a firm grip and maintaining control throughout the process. 3. Shaping with a file or grinder: Once the profile is cut to the desired length, you may need to shape or smooth the edges. This can be done using a file or grinder with an aluminum grinding wheel or sanding disc. Carefully work the file or grinder along the edges, shaping or smoothing them as needed. Take care not to apply too much pressure, as aluminum can heat up quickly and may distort or become damaged. Remember to wear appropriate safety gear, such as gloves and eye protection, when working with aluminum profiles. Additionally, it's always a good idea to practice on scrap pieces first to familiarize yourself with the techniques and tools before working on the final product.

- Q: Can aluminum profiles be used in modular wall systems?

- Yes, aluminum profiles can be used in modular wall systems. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular walls. They can be easily assembled, disassembled, and reconfigured to meet specific design requirements. Additionally, aluminum profiles offer excellent structural integrity and can accommodate various finishes, such as glass panels or cladding, enhancing the aesthetics of the modular wall system.

- Q: This question asks whether aluminum profiles can be utilized as a material for exterior wall insulation panels.

- <p>Yes, aluminum profiles can be used for exterior wall insulation panels. They are commonly used due to their durability, corrosion resistance, and lightweight properties. Aluminum profiles provide structural support and can be combined with insulation materials such as polyurethane or mineral wool to create efficient thermal insulation. They are also compatible with various cladding systems, making them a versatile choice for exterior wall insulation.</p>

- Q: Fenglv aluminum material how ah? What aluminum materials do you use for windows and doors?

- Domestic aluminum quality is about the same, mainly you installed in the window accessories, is the key to the life of the service, recommend several brands Bar Reid Jan Ron Lixin spring is not recommended, quality is not very rely on live

- Q: Aluminum profile 606360056061, T5 and T6 hardness GB, how much?

- Generally divided into Vivtorinox hardness, Rockwell hardness and Vickers hardness and webster hardness. Our enterprises are generally in accordance with webster hardness test, GB 6063-T5 8HW 6063-T6 11.5HW6005-T5 15HW 6005-T6 15HW6061-T5 15HW 6061-T6 15HWIf you need other hardness units, you can refer to the conversion

- Q: Can aluminum profiles be used in solar reflector systems?

- Indeed, aluminum profiles find application in solar reflector systems. The utilization of aluminum in solar reflector systems is widespread owing to its extraordinary corrosion resistance and high reflectivity. The malleability of aluminum profiles allows for effortless customization and shaping, facilitating the optimization of sunlight reflection onto the solar panels. Furthermore, the lightweight and durable nature of aluminum profiles render them highly suitable for outdoor usage. Consequently, aluminum profiles emerge as a prudent and efficient selection for solar reflector systems.

- Q: Identify the key elements to evaluate when choosing aluminum profiles for a particular project.

- <p>When selecting aluminum profiles for a specific project, consider the following factors: 1) Load-bearing capacity, ensuring the profile can support the intended weight and stress; 2) Dimensional stability, to maintain structural integrity over time; 3) Corrosion resistance, especially for outdoor or humid environments; 4) Aesthetics, matching the profile's appearance with the project's design; 5) Cost-effectiveness, balancing quality with budget constraints; 6) Availability of the profile, considering lead times and supply chain reliability; 7) Ease of fabrication and assembly, which can affect construction time and labor costs; 8) Thermal properties, important for energy efficiency in buildings; 9) Compliance with industry standards and regulations; 10) Customizability, for projects with unique specifications or design requirements.</p>

- Q: Can aluminum profiles be used for exhibition booths?

- Indeed, exhibition booths can make use of aluminum profiles. These profiles possess the qualities of being lightweight, durable, and simple to assemble, rendering them a favored option for constructing exhibition booths. They can be personalized effortlessly to suit particular design necessities and can be employed for fabricating walls, frames, and structures to showcase products and promotional materials. Furthermore, aluminum profiles can be conveniently transported and stored, making them an ideal selection for exhibition booths requiring multiple setups and dismantlings. Ultimately, aluminum profiles provide adaptability and convenience in fabricating visually captivating and practical exhibition booths.

- Q: What are the load-bearing capacities of different aluminum profile shapes?

- The load-bearing capacities of various aluminum profile shapes differ depending on several factors, including the specific aluminum alloy used, the profile's size and dimensions, and its intended application. Aluminum profiles, also referred to as extrusions, are available in a wide range of shapes, which include I-beams, T-beams, square tubes, rectangular tubes, angles, and channels. Each shape possesses a distinct load-bearing capacity due to its structural design and cross-sectional properties. For instance, I-beams exhibit a high load-bearing capacity due to their shape, enabling efficient distribution of weight along the flanges. These profiles are commonly employed in structural applications that require supporting heavy loads. T-beams, on the other hand, possess a load-bearing capacity akin to I-beams but feature a different cross-sectional shape. They find utility in applications necessitating a flat surface on one side, such as in the construction or automotive industries. Square and rectangular tubes are versatile profiles widely used in building structures, frames, and support systems. Their load-bearing capacity is contingent upon the tube's wall thickness and size. Angles and channels, characterized by their L-shaped and U-shaped cross-sections respectively, are commonly employed in the construction and manufacturing sectors. The load-bearing capacity of these profiles is influenced by their size and dimensions. It is important to note that manufacturers typically provide the load-bearing capacities of aluminum profiles, which should be consulted for specific applications. Moreover, engineering calculations and considerations, such as deflection, bending moments, and safety factors, should be taken into account when determining the appropriate aluminum profile shape and size for a given load-bearing requirement.

- Q: The subject is aluminum bearing in what u ~ on both sides of the track?? How can the track be fitted into this slot? Both sides secure 50Mechanical expert answers!The subject is aluminum bearing in what u ~ on both sides of the track?? How can the track be fitted into this slot? How can the seat of fixed motor on both sides be connected with the section bar?

- A little understanding of machinery, not what you say master. Say, for reference only. No, please correct me.

Send your message to us

Aluminum Window Extrusion Profiles - Alloy 6082 Aluminium Extrusion Profiles for Industrial Application

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 2 m.t.

- Supply Capability:

- 60000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords