All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What safety precautions should be followed when working with aluminum profiles in industrial applications?

When working with aluminum profiles in industrial applications, several safety precautions should be followed:

1. Personal Protective Equipment (PPE): Workers should wear appropriate PPE, including safety glasses, gloves, and steel-toe boots, to protect themselves from potential hazards.

2. Handling and Storage: Aluminum profiles should be handled and stored carefully to prevent any damage or injuries. They should be properly stacked, secured, and stored in a designated area to avoid tripping hazards.

3. Cutting and Machining: When cutting or machining aluminum profiles, workers should use appropriate tools and techniques to minimize the risk of accidents. Cutting tools should be sharp and in good condition, and proper cutting techniques should be followed to prevent kickback or material binding.

4. Ventilation: Adequate ventilation is crucial to prevent the accumulation of hazardous fumes or dust released during various aluminum processing operations. Proper ventilation systems should be installed and maintained to ensure a safe working environment.

5. Fire Safety: Aluminum is highly flammable, so it is essential to have fire safety measures in place. Workers should be trained in fire safety procedures and have easy access to fire extinguishers and emergency exits. Flammable materials should be stored separately, and smoking should be strictly prohibited in the designated work areas.

6. Training and Education: Proper training and education on handling aluminum profiles and the associated hazards should be provided to all workers. They should be aware of safety protocols, emergency procedures, and how to use equipment correctly to minimize the risk of accidents.

By following these safety precautions, the risk of accidents and injuries when working with aluminum profiles in industrial applications can be significantly reduced.

How do you ensure the structural integrity and load-bearing capacity of aluminum profile systems?

To ensure the structural integrity and load-bearing capacity of aluminum profile systems, several measures can be taken.

Firstly, thorough engineering analysis and calculations are conducted to determine the appropriate profile dimensions, section properties, and connection methods. This ensures that the system can withstand the anticipated loads and forces.

Secondly, aluminum profiles are carefully chosen and sourced from reputable suppliers that meet industry standards and specifications. This guarantees the quality and strength of the materials used.

Additionally, proper fabrication techniques, such as precise cutting, drilling, and welding, are employed to maintain the integrity of the profiles and their connections. Close attention is paid to ensure accurate alignment and secure fastening.

Furthermore, regular inspections and quality control checks are carried out during the manufacturing and installation processes. This helps identify any potential issues or defects that may compromise the structural stability of the system.

Lastly, load testing is often performed on prototypes or representative samples to validate the calculated load-bearing capacity and ensure the system meets the required safety factors.

By implementing these measures, the structural integrity and load-bearing capacity of aluminum profile systems can be effectively ensured.

What is the expected shelf life of aluminum profiles when stored in controlled conditions?

The expected shelf life of aluminum profiles when stored in controlled conditions can vary depending on various factors such as the specific alloy used, the quality of the profiles, and the storage conditions. However, typically, aluminum profiles can have a shelf life of several years to decades when stored in controlled environments that are free from excessive moisture, humidity, and temperature fluctuations. Regular inspection and maintenance can also help prolong their lifespan.

What is extrusion, and how is it used in making aluminum profiles?

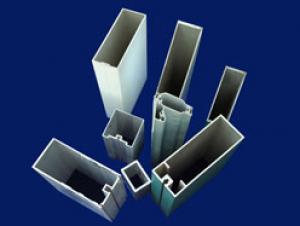

Extrusion is a manufacturing process that involves forcing a material, such as aluminum, through a die to create a specific shape or profile. In the case of making aluminum profiles, the process starts with heating a billet of aluminum to a specific temperature and then pushing it through a shaped opening in a die using a hydraulic press. This results in the aluminum taking on the shape of the die, forming a continuous profile. The extrusion process allows for the creation of complex cross-sectional profiles with consistent dimensions and excellent surface finish. The profiles produced can be further processed, such as cutting, drilling, or bending, to meet specific requirements for various applications in industries like construction, automotive, and aerospace.

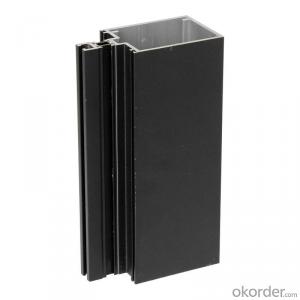

Wholesale Aluminum Profiles from supplier in Laos

Whether you are in need of standard aluminum profiles or customized solutions, our team of experts is ready to assist you. We offer a wide range of aluminum profiles, including but not limited to, extrusions, sheets, plates, rods, and tubes. Our products are available in various sizes, shapes, and finishes to suit your specific requirements.

In addition to supplying high-quality aluminum profiles, we also provide comprehensive sales and quotation services. Our dedicated sales team is committed to understanding your needs and offering the most suitable products at competitive prices. We strive to provide accurate and timely quotations, ensuring a seamless procurement process for our customers.

Furthermore, our technical support services are designed to assist you throughout your project. We have a team of experienced engineers who can provide guidance and expertise on product selection, design, installation, and maintenance. We understand the importance of delivering reliable and efficient solutions, and our technical support team is here to ensure your project's success.

As a subsidiary of CNBM, a Fortune Global 500 company, we bring a wealth of resources and expertise to the table. Our strong global network allows us to source high-quality materials and deliver them to you in a timely manner. We adhere to strict quality control standards to ensure that our products meet international industry standards.

With our extensive market experience in Laos, we understand the unique challenges and requirements of projects in the region. We are well-equipped to provide valuable insights and recommendations tailored to your specific needs. Whether you are working on a small-scale project or a large-scale development, we have the knowledge and expertise to support you every step of the way.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by delivering exceptional products and services. Our commitment to quality, efficiency, and customer support sets us apart in the industry.

Contact us today to discuss your aluminum profile needs and let us provide you with the best procurement solutions in Laos.

In addition to supplying high-quality aluminum profiles, we also provide comprehensive sales and quotation services. Our dedicated sales team is committed to understanding your needs and offering the most suitable products at competitive prices. We strive to provide accurate and timely quotations, ensuring a seamless procurement process for our customers.

Furthermore, our technical support services are designed to assist you throughout your project. We have a team of experienced engineers who can provide guidance and expertise on product selection, design, installation, and maintenance. We understand the importance of delivering reliable and efficient solutions, and our technical support team is here to ensure your project's success.

As a subsidiary of CNBM, a Fortune Global 500 company, we bring a wealth of resources and expertise to the table. Our strong global network allows us to source high-quality materials and deliver them to you in a timely manner. We adhere to strict quality control standards to ensure that our products meet international industry standards.

With our extensive market experience in Laos, we understand the unique challenges and requirements of projects in the region. We are well-equipped to provide valuable insights and recommendations tailored to your specific needs. Whether you are working on a small-scale project or a large-scale development, we have the knowledge and expertise to support you every step of the way.

At our company, customer satisfaction is our top priority. We strive to build long-term relationships with our clients by delivering exceptional products and services. Our commitment to quality, efficiency, and customer support sets us apart in the industry.

Contact us today to discuss your aluminum profile needs and let us provide you with the best procurement solutions in Laos.