All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

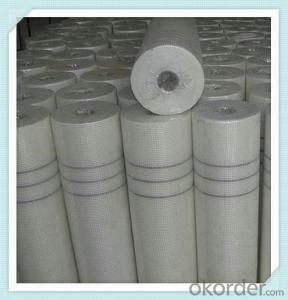

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

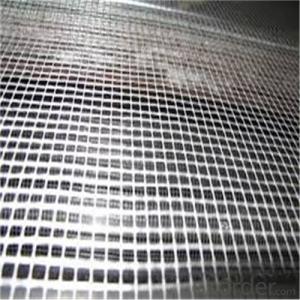

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Fiberglass Chopped StrandView More

Fiberglass Mesh ClothView More

Composite PipesView More

FRP Pultrusion ProfilesView More

Fiberglass Mat TissueView More

Fiberglass FabricsView More

Fiberglass MeshView More

Composite TankView More

Fiberglass Mesh tapeView More

PolymerView More

FRP Roofing PanelView More

Fiberglass RovingView More

Q & A

Are there any specific techniques for cutting fiberglass?

Yes, there are specific techniques for cutting fiberglass to ensure clean and precise cuts. Some common techniques include using a power tool equipped with a fiberglass cutting blade, such as a jigsaw or reciprocating saw, to cut through the material. It is important to wear appropriate safety gear, such as goggles and a respirator, to protect oneself from fiberglass dust. Additionally, scoring the surface with a utility knife before cutting can help prevent splintering.

What are the different curing methods for fiberglass products?

There are several curing methods for fiberglass products, including room temperature curing, heat curing, and UV curing. Room temperature curing involves allowing the fiberglass to cure naturally at ambient temperatures, which can take several hours or days depending on the specific resin used. Heat curing, on the other hand, involves applying controlled heat to accelerate the curing process, reducing the overall curing time. UV curing utilizes ultraviolet light to initiate and accelerate the curing reaction, providing a quick and efficient curing method, especially for smaller or thinner fiberglass products.

What are the potential health risks associated with fiberglass exposure?

Potential health risks associated with fiberglass exposure include skin irritation, itching, and rashes. Inhaling fiberglass particles can lead to respiratory issues such as coughing, wheezing, and difficulty breathing. Prolonged or intense exposure may increase the risk of developing lung diseases like fibrosis or asthma. It's important to take necessary precautions and use protective measures when working with or around fiberglass to minimize these health risks.

What industries use fiberglass supply?

Many industries utilize fiberglass supply, including construction, automotive, aerospace, marine, wind energy, and electrical industries.

Can fiberglass supply be recycled?

Yes, fiberglass supply can be recycled. Fiberglass recycling involves breaking down the material into its individual components and then reusing them to create new products.

Wholesale Fiberglass Supply from supplier in Laos

With our strong partnership with CNBM, we have access to a global network of suppliers and manufacturers, ensuring that we can source the highest quality Fiberglass Supply products at competitive prices. Our team is constantly monitoring market trends and innovations, allowing us to offer you the latest and most advanced solutions in Fiberglass Supply.

In addition to our product offerings, we also provide a range of value-added services such as logistics management, warehousing, and after-sales support. We understand the importance of timely delivery and efficient logistics, and we work closely with our partners to ensure that your orders are delivered on time and in perfect condition.

At our company, we prioritize customer satisfaction above all else. We strive to build long-term relationships with our clients, based on trust, reliability, and mutual success. Our team is always available to answer any questions or concerns you may have, and we are committed to resolving any issues promptly and effectively.

So, whether you are in the construction, manufacturing, or industrial sector, trust our expertise and experience to meet all your Fiberglass Supply needs in Laos. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.

In addition to our product offerings, we also provide a range of value-added services such as logistics management, warehousing, and after-sales support. We understand the importance of timely delivery and efficient logistics, and we work closely with our partners to ensure that your orders are delivered on time and in perfect condition.

At our company, we prioritize customer satisfaction above all else. We strive to build long-term relationships with our clients, based on trust, reliability, and mutual success. Our team is always available to answer any questions or concerns you may have, and we are committed to resolving any issues promptly and effectively.

So, whether you are in the construction, manufacturing, or industrial sector, trust our expertise and experience to meet all your Fiberglass Supply needs in Laos. Contact us today to discuss your requirements and let us provide you with the best solutions for your projects.