All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

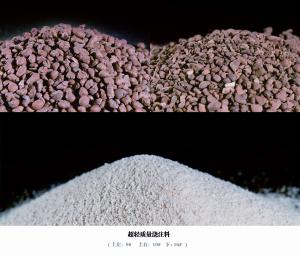

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do monolithic refractories perform in molten ceramic environments?

Monolithic refractories exhibit excellent performance in molten ceramic environments due to their high thermal shock resistance, chemical inertness, and ability to withstand extreme temperatures. They provide superior insulation and erosion resistance, allowing them to effectively contain and protect the molten ceramic materials.

Can monolithic refractories be used for lining boilers in power plants?

Yes, monolithic refractories can be used for lining boilers in power plants. Monolithic refractories are a type of refractory material that can be easily shaped and installed without the need for individual bricks. They have excellent thermal shock resistance and can withstand high temperatures, making them suitable for use in boilers. Additionally, monolithic refractories offer superior performance in terms of durability and insulation, ensuring efficient and reliable operation of the power plant boilers.

Can monolithic refractories be used in chemical reactors?

Yes, monolithic refractories can be used in chemical reactors. Monolithic refractories are versatile and can withstand high temperatures, corrosive environments, and thermal shocks, making them suitable for various industrial applications, including chemical reactors. Their ability to be shaped and installed in complex geometries allows for efficient lining of reactors, enhancing their performance and durability.

How do monolithic refractories handle thermal conductivity and insulation?

Monolithic refractories handle thermal conductivity and insulation by having low thermal conductivity, meaning they are resistant to heat transfer. They also have high insulation properties, allowing them to retain heat and prevent it from escaping.

Wholesale Monolithic Refractories from supplier in Laos

Our team is ready to assist you with any inquiries, provide quotations, and offer technical support. Contact us today to discuss your Monolithic Refractories needs in Laos and let us help you find the perfect solutions for your projects.

Hot Search

- Monolithic Refractories in Lebanon

- Ceramic Fiber Products in Mongolia

- Refractory Bricks in Bahrain

- Raw Materials For Refractory in Ecuador

- Refractory Bricks in Oman

- Monolithic Refractories in Comoros

- Refractory Bricks in Ethiopia

- Monolithic Refractories in Ireland

- Ceramic Fiber Products in Nigeria

- Ceramic Fiber Products in Nauru