All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

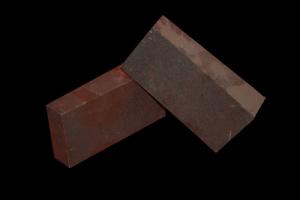

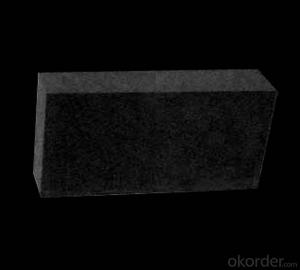

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Are refractory bricks environmentally friendly?

Refractory bricks are not considered environmentally friendly due to the high energy consumption and emissions associated with their production process. Additionally, their disposal poses challenges as they are not biodegradable and can release toxic substances when incinerated. However, efforts are being made to develop more sustainable alternatives in the field of refractory materials.

What is the cost of refractory bricks?

The cost of refractory bricks can vary depending on factors such as size, quality, and quantity. It is best to contact suppliers or manufacturers for specific pricing information.

Can refractory bricks be used in steel manufacturing?

Yes, refractory bricks can be used in steel manufacturing. Refractory bricks are specifically designed to withstand high temperatures and harsh conditions, making them suitable for lining furnaces, kilns, and other equipment used in steel production. These bricks provide thermal insulation, reduce heat loss, and protect the steelmaking vessel from chemical reactions and wear, ensuring efficient and reliable steel manufacturing processes.

Can refractory bricks be used in pulp and paper mills?

Yes, refractory bricks can be used in pulp and paper mills. These bricks are designed to withstand high temperatures and harsh chemical environments, making them suitable for use in various industrial applications, including pulp and paper mills. They provide insulation and protection for the equipment and structures used in these mills, ensuring efficient and safe operations.

How do refractory bricks contribute to reducing noise pollution in industrial processes?

Refractory bricks are often used in industrial processes as insulation materials due to their ability to withstand high temperatures. By providing effective insulation, they help to contain the noise generated by the machinery and equipment used in these processes. The dense and heavy nature of refractory bricks absorbs and dampens the sound waves, reducing noise pollution levels and creating a quieter working environment.

Wholesale Refractory Bricks from supplier in Laos

We understand the unique requirements and challenges of the Laos market, and our team of experts is dedicated to delivering high-quality refractory bricks that meet your specific needs. Whether you require bricks for high-temperature furnaces, kilns, or other industrial applications, we have the right solution for you.

Our sales team is committed to providing excellent customer service and ensuring a smooth procurement process. We offer competitive prices and flexible payment terms to accommodate your budget and project timelines. Additionally, our experienced technicians are available to provide technical support and guidance, ensuring that you select the most suitable refractory bricks for your application.

Being a subsidiary of CNBM, a leading global company in the building materials industry, we have access to a vast network of suppliers and resources. This allows us to source the highest quality refractory bricks and ensure timely delivery to your site in Laos.

We take pride in our commitment to customer satisfaction and our ability to provide comprehensive solutions for all your refractory brick needs. Contact us today to discuss your requirements and experience the convenience and reliability of working with us.

Our sales team is committed to providing excellent customer service and ensuring a smooth procurement process. We offer competitive prices and flexible payment terms to accommodate your budget and project timelines. Additionally, our experienced technicians are available to provide technical support and guidance, ensuring that you select the most suitable refractory bricks for your application.

Being a subsidiary of CNBM, a leading global company in the building materials industry, we have access to a vast network of suppliers and resources. This allows us to source the highest quality refractory bricks and ensure timely delivery to your site in Laos.

We take pride in our commitment to customer satisfaction and our ability to provide comprehensive solutions for all your refractory brick needs. Contact us today to discuss your requirements and experience the convenience and reliability of working with us.

Hot Search

- Monolithic Refractories in Sri Lanka

- Ceramic Fiber Products in Mozambique

- Refractory Bricks in Ecuador

- Raw Materials For Refractory in Malaysia

- Monolithic Refractories in Guinea

- Raw Materials For Refractory in Mali

- Raw Materials For Refractory in Swaziland

- Raw Materials For Refractory in Samoa

- Monolithic Refractories in Bolivia

- Monolithic Refractories in Norway