All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the thermal shock resistance testing methods for refractory products?

There are several thermal shock resistance testing methods for refractory products. One common method is the water quench test, where the refractory specimen is heated to a specific temperature and then rapidly subjected to cold water. Another method is the air quench test, where the specimen is exposed to high temperatures and then rapidly cooled using compressed air. Additionally, there is the thermal cycling test, which involves subjecting the specimen to repeated cycles of heating and cooling. These testing methods help evaluate the ability of refractory products to withstand sudden temperature changes without experiencing damage or failure.

What are the benefits of using calcium oxide nanoparticles as a raw material in refractory production?

Using calcium oxide nanoparticles as a raw material in refractory production offers several benefits. Firstly, these nanoparticles provide enhanced mechanical strength and stability to the refractory material, resulting in improved durability and longevity. Additionally, the high surface area of the nanoparticles allows for better heat resistance and insulation properties, making the refractory more effective in withstanding high temperatures. Furthermore, the small size of the nanoparticles enables better control over the microstructure of the refractory, leading to improved performance and reliability in various industrial applications. Overall, the utilization of calcium oxide nanoparticles as a raw material in refractory production enhances the overall quality and performance of the refractory material.

How do raw materials impact the resistance to molten metal attack of refractory products?

Raw materials play a crucial role in determining the resistance of refractory products to molten metal attack. The selection and composition of raw materials significantly influence the physical and chemical properties of the refractory, such as its porosity, density, thermal conductivity, and chemical stability. By carefully choosing raw materials with high melting points, low reactivity with molten metals, and excellent thermal shock resistance, refractory products can be engineered to withstand high temperatures and resist corrosion caused by molten metal contact.

Which refractory raw materials are commonly used in high-temperature applications?

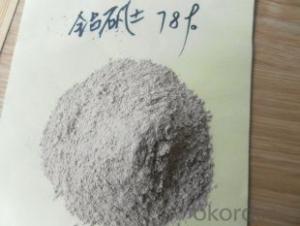

Some common refractory raw materials used in high-temperature applications include alumina, silica, magnesia, chromite, zircon, and carbon.

Wholesale Raw Materials For Refractory from supplier in Swaziland

We understand the importance of raw materials for the refractory industry and are committed to providing high-quality products to our clients in Swaziland. Our team of experts is knowledgeable and experienced in the field, ensuring that we can offer the best solutions to meet your specific requirements.

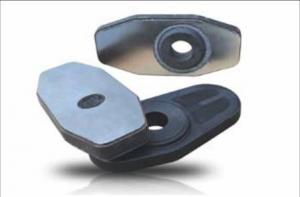

We offer a wide range of raw materials for refractory applications, including various types of minerals, aggregates, binders, and additives. Our products are sourced from reliable suppliers and undergo strict quality control measures to ensure their performance and durability.

In addition to supplying raw materials, we also provide sales and technical support services. Our dedicated team is available to assist you with product selection, offer competitive quotations, and provide technical guidance throughout your project. We understand the unique challenges and requirements of the Swaziland market and can offer valuable insights to help you make informed decisions.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the advantage of a strong global network and extensive resources. This allows us to provide comprehensive procurement services, ensuring a seamless supply chain for your raw materials needs. Our commitment to customer satisfaction and our ability to deliver on time and within budget have made us a trusted partner in the industry.

Whether you are involved in the production of refractory bricks, castables, or other refractory products, we have the expertise and resources to support your projects in Swaziland. Contact us today for more information and let us be your trusted supplier of raw materials for refractory applications.

We offer a wide range of raw materials for refractory applications, including various types of minerals, aggregates, binders, and additives. Our products are sourced from reliable suppliers and undergo strict quality control measures to ensure their performance and durability.

In addition to supplying raw materials, we also provide sales and technical support services. Our dedicated team is available to assist you with product selection, offer competitive quotations, and provide technical guidance throughout your project. We understand the unique challenges and requirements of the Swaziland market and can offer valuable insights to help you make informed decisions.

As a subsidiary platform of CNBM, a Fortune Global 500 company, we have the advantage of a strong global network and extensive resources. This allows us to provide comprehensive procurement services, ensuring a seamless supply chain for your raw materials needs. Our commitment to customer satisfaction and our ability to deliver on time and within budget have made us a trusted partner in the industry.

Whether you are involved in the production of refractory bricks, castables, or other refractory products, we have the expertise and resources to support your projects in Swaziland. Contact us today for more information and let us be your trusted supplier of raw materials for refractory applications.

Hot Search

- Monolithic Refractories in Germany

- Ceramic Fiber Products in Mauritania

- Refractory Bricks in Sweden

- Raw Materials For Refractory in Vietnam

- Refractory Bricks in Uzbekistan

- Raw Materials For Refractory in Estonia

- Raw Materials For Refractory in Laos

- Ceramic Fiber Products in Armenia

- Ceramic Fiber Products in Tonga

- Monolithic Refractories in Ethiopia