All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

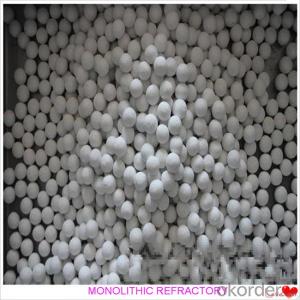

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

Can monolithic refractories be used for lining ladle pouring spouts?

Yes, monolithic refractories can be used for lining ladle pouring spouts. Monolithic refractories are advantageous for lining pouring spouts as they can be easily applied and provide good resistance to thermal shock and erosion. They also offer flexibility in terms of shape and size, making them suitable for lining ladle pouring spouts.

How are monolithic refractories being used in the aluminum industry?

Monolithic refractories are extensively used in the aluminum industry for various applications. They are commonly utilized in the lining of furnaces, kilns, and other high-temperature equipment involved in the production and processing of aluminum. Monolithic refractories provide excellent thermal insulation, resistance to thermal shock, and durability, making them ideal for maintaining the required high temperatures and protecting the structural integrity of the equipment. Additionally, these refractories help optimize energy efficiency, improve process control, and ensure a longer lifespan for the equipment, thereby enhancing productivity and reducing maintenance costs in the aluminum industry.

How do monolithic refractories provide resistance to thermal fatigue in boilers?

Monolithic refractories provide resistance to thermal fatigue in boilers by possessing excellent thermal shock resistance and high thermal conductivity. This enables them to withstand the repeated thermal cycles and rapid temperature changes experienced in boiler operations without cracking or deteriorating. Additionally, their ability to expand and contract uniformly helps in reducing the stress caused by thermal cycling, thus enhancing their resistance to thermal fatigue.

Can monolithic refractories be used in the construction of cement rotary kilns?

Yes, monolithic refractories can be used in the construction of cement rotary kilns. They are often preferred due to their flexibility, ease of installation, and ability to withstand high temperatures and thermal shock. Monolithic refractories provide a reliable lining solution for cement rotary kilns, ensuring efficient and durable operation.

How do monolithic refractories handle neutral atmospheres?

Monolithic refractories are highly effective in handling neutral atmospheres due to their ability to resist high temperatures and chemical corrosion. They maintain their structural integrity and performance without any significant degradation or reaction in such environments.

Wholesale Monolithic Refractories from supplier in Germany

With our team of knowledgeable and skilled professionals, we can assist you in selecting the most suitable Monolithic Refractories products for your specific requirements. We understand the importance of quality and reliability in the refractories industry, which is why we only work with trusted manufacturers and suppliers.

Our sales team is dedicated to providing excellent customer service and ensuring your satisfaction throughout the purchasing process. We can provide competitive pricing and timely delivery to meet your project deadlines.

In addition to sales, we also offer technical support to help you with any questions or issues that may arise during the installation or use of our products. Our technical experts can provide guidance on product selection, installation techniques, and troubleshooting.

As a subsidiary of CNBM, we have access to a global network of resources and expertise. This allows us to stay up-to-date with the latest advancements in Monolithic Refractories technology and offer innovative solutions to our customers.

We are committed to building long-term relationships with our customers and strive to exceed their expectations in terms of product quality, service, and support. Contact us today to discuss your Monolithic Refractories needs in Germany, and let us provide you with the solutions you require.

Our sales team is dedicated to providing excellent customer service and ensuring your satisfaction throughout the purchasing process. We can provide competitive pricing and timely delivery to meet your project deadlines.

In addition to sales, we also offer technical support to help you with any questions or issues that may arise during the installation or use of our products. Our technical experts can provide guidance on product selection, installation techniques, and troubleshooting.

As a subsidiary of CNBM, we have access to a global network of resources and expertise. This allows us to stay up-to-date with the latest advancements in Monolithic Refractories technology and offer innovative solutions to our customers.

We are committed to building long-term relationships with our customers and strive to exceed their expectations in terms of product quality, service, and support. Contact us today to discuss your Monolithic Refractories needs in Germany, and let us provide you with the solutions you require.

Hot Search

- Monolithic Refractories in Afghanistan

- Ceramic Fiber Products in Zimbabwe

- Refractory Bricks in Singapore

- Raw Materials For Refractory in Chile

- Ceramic Fiber Products in Turkmenistan

- Ceramic Fiber Products in Algeria

- Raw Materials For Refractory in Kazakhstan

- Refractory Bricks in Burundi

- Monolithic Refractories in Maldives

- Refractory Bricks in Nauru