All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

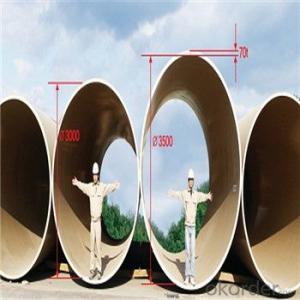

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How do composite pipes compare to fiberglass-reinforced plastic (FRP) pipes?

Composite pipes and fiberglass-reinforced plastic (FRP) pipes are similar in that they both offer superior strength and corrosion resistance compared to traditional materials like steel or concrete. However, composite pipes generally have a wider range of reinforcement materials, including fiberglass, carbon fiber, or aramid fibers, which can be tailored to specific applications. On the other hand, FRP pipes typically use fiberglass as the primary reinforcement material. This difference allows composite pipes to potentially offer higher strength, flexibility, and temperature resistance compared to FRP pipes. Ultimately, the choice between composite pipes and FRP pipes depends on the specific requirements and conditions of the project.

Are composite pipes resistant to UV degradation in outdoor installations?

Yes, composite pipes are generally resistant to UV degradation in outdoor installations. Composite materials, such as fiberglass or carbon fiber reinforced polymers, are designed with enhanced UV resistance properties, making them suitable for prolonged exposure to sunlight without significant degradation or deterioration.

Can composite pipes be used for gas transportation?

Yes, composite pipes can be used for gas transportation. Composite pipes are made of a combination of materials such as fiberglass, carbon fiber, or other reinforced polymers, which provide excellent resistance to corrosion and high-pressure capabilities. These pipes are lightweight, durable, and have low thermal conductivity, making them suitable for transporting gases safely and efficiently.

Do composite pipes have any restrictions on the maximum fluid pressure they can handle?

Yes, composite pipes do have restrictions on the maximum fluid pressure they can handle. The maximum fluid pressure capacity of composite pipes is determined by their design and material composition. These pipes are typically engineered to withstand specific pressure limits, and exceeding these limits can lead to structural failure or leakage. Therefore, it is important to consider the maximum fluid pressure specifications provided by the manufacturer when using composite pipes.

Wholesale Composite Pipes from supplier in Germany

Whether you require Composite Pipes for industrial applications, oil and gas pipelines, or water supply systems, we have the expertise to meet your specific requirements. Our team of experienced sales professionals will work closely with you to understand your needs and provide tailored solutions that meet your project specifications.

In addition to our sales services, we also offer quoting services to ensure that you receive competitive pricing for your Composite Pipes requirements. Our strong partnership with leading manufacturers allows us to negotiate favorable terms and pass on cost savings to our customers.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire project lifecycle. From product selection to installation and maintenance, we are committed to delivering exceptional customer service and ensuring your project's success.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This enables us to provide comprehensive procurement services, ensuring that you have access to a wide range of high-quality Composite Pipes products. We work closely with our suppliers to maintain strict quality control standards, ensuring that you receive products that meet the highest industry standards.

With our extensive product range and market development experience in Germany, we are well-positioned to provide valuable expertise and support for your projects. Contact us today to discuss your Composite Pipes requirements and discover how we can help you achieve your project goals.

In addition to our sales services, we also offer quoting services to ensure that you receive competitive pricing for your Composite Pipes requirements. Our strong partnership with leading manufacturers allows us to negotiate favorable terms and pass on cost savings to our customers.

Furthermore, our technical support team is available to provide guidance and assistance throughout the entire project lifecycle. From product selection to installation and maintenance, we are committed to delivering exceptional customer service and ensuring your project's success.

As a subsidiary of CNBM, we benefit from the resources and expertise of a Fortune Global 500 company. This enables us to provide comprehensive procurement services, ensuring that you have access to a wide range of high-quality Composite Pipes products. We work closely with our suppliers to maintain strict quality control standards, ensuring that you receive products that meet the highest industry standards.

With our extensive product range and market development experience in Germany, we are well-positioned to provide valuable expertise and support for your projects. Contact us today to discuss your Composite Pipes requirements and discover how we can help you achieve your project goals.

Hot Search

- Fiberglass Chopped Strand in South Korea

- Fiberglass Mesh Cloth in Tajikistan

- Composite Pipes in Guyana

- FRP Pultrusion Profiles in Slovenia

- Fiberglass Mat Tissue in Honduras

- Fiberglass Fabrics in Vietnam

- Fiberglass Mesh in Oman

- Composite Tank in Denmark

- Fiberglass Mesh tape in Benin

- Polymer in Argentina