All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

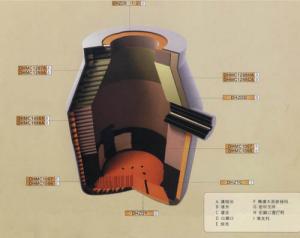

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How do refractory bricks perform in corrosive environments?

Refractory bricks excel in corrosive environments due to their high resistance to chemical reactions and erosion. They are designed to withstand extreme temperatures and harsh conditions, making them ideal for applications where corrosion is a concern. The materials used in refractory bricks, such as alumina, silica, and magnesia, offer excellent protection against corrosive agents, ensuring durability and longevity in such environments.

Can refractory bricks be used for glass melting furnaces?

Yes, refractory bricks can be used for glass melting furnaces. Refractory bricks are specifically designed to withstand high temperatures and provide insulation, making them suitable for use in glass melting furnaces where extreme heat is required.

How do refractory bricks contribute to the reduction of process interruptions?

Refractory bricks contribute to the reduction of process interruptions by providing high resistance to heat, corrosion, and mechanical wear. They can withstand extreme temperatures and harsh conditions, ensuring the stability and durability of industrial processes. By maintaining the integrity of furnaces, kilns, and other high-temperature equipment, refractory bricks minimize the risk of breakdowns and downtime, thus reducing interruptions in the production process.

Wholesale Refractory Bricks from supplier in Singapore

Contact us today to discuss your refractory needs and let us provide you with the best solutions. We look forward to serving you and contributing to the success of your projects in Singapore.

Hot Search

- Monolithic Refractories in Tajikistan

- Ceramic Fiber Products in Italy

- Refractory Bricks in Uruguay

- Raw Materials For Refractory in Nicaragua

- Raw Materials For Refractory in Malaysia

- Raw Materials For Refractory in Bhutan

- Refractory Bricks in Laos

- Ceramic Fiber Products in Armenia

- Raw Materials For Refractory in France

- Refractory Bricks in Japan