All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

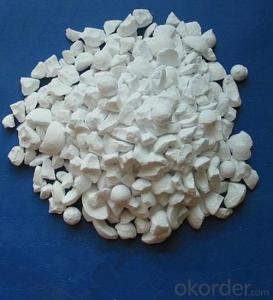

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

What are the properties and applications of specialized, ultra-high-temperature refractories?

Specialized, ultra-high-temperature refractories possess exceptional properties that make them ideal for applications requiring extreme heat resistance. These refractories typically have high melting points, low thermal expansion coefficients, excellent thermal shock resistance, and superior mechanical strength. They are commonly used in industries such as steelmaking, glass manufacturing, and aerospace for applications like lining furnaces, kilns, and rocket nozzles. These refractories can withstand temperatures exceeding 3000 degrees Celsius, enabling them to withstand the harsh conditions of these high-temperature environments.

How does mullite enhance the performance of refractory materials?

Mullite enhances the performance of refractory materials through its unique properties such as high melting point, excellent thermal shock resistance, and low thermal expansion coefficient. These characteristics make mullite an ideal additive in refractory materials as it improves their overall strength, durability, and resistance to extreme temperatures and rapid temperature changes. Additionally, mullite's ability to withstand thermal cycling and chemical corrosion ensures the longevity and stability of refractory materials, making them more effective in high-temperature applications.

What are the raw materials used in the manufacturing of acid-resistant refractories?

The raw materials commonly used in the manufacturing of acid-resistant refractories include silica, alumina, magnesia, and zirconia. These materials possess high resistance to acidic environments and are crucial for maintaining the integrity of refractory linings in industries such as petrochemical, chemical, and metallurgical.

How do different types of corundum compare in terms of performance in refractory applications?

Different types of corundum, such as white corundum, brown corundum, and black corundum, differ in their performance in refractory applications. White corundum is known for its high purity and excellent thermal stability, making it suitable for high-temperature environments. Brown corundum, on the other hand, offers good thermal shock resistance and high mechanical strength, making it suitable for applications that require toughness. Black corundum is commonly used in abrasive applications due to its hardness and durability. Overall, the choice of corundum for refractory applications depends on the specific requirements of the application, such as temperature, mechanical stress, and chemical environment.

Wholesale Raw Materials For Refractory from supplier in Bhutan

With our strong presence in Bhutan, we are well-positioned to provide you with the highest quality raw materials for refractory products. Whether you require materials for steel, cement, glass, or other industries, we have a wide range of options to meet your specific needs. Our team of experts will work closely with you to understand your requirements and recommend the most suitable materials for your projects.

In addition to our sales and procurement services, we also offer technical support to ensure the successful implementation of your projects. Our experienced engineers are available to provide guidance on product selection, installation techniques, and troubleshooting. We understand the importance of timely and efficient support, and we are committed to helping you overcome any challenges you may face.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and expertise. This allows us to offer competitive prices and ensure the availability of high-quality materials. We are committed to delivering exceptional value to our customers and building long-term partnerships based on trust and reliability.

We invite you to experience the wonders of Bhutan while working with us. Whether you are visiting for business or pleasure, we can help you make the most of your time in this enchanting kingdom. From arranging cultural tours to providing recommendations for local attractions, our team is here to assist you in every way possible. Let us be your guide to the captivating allure of Bhutan while meeting your raw material needs. Contact us today to learn more about our services and how we can support your projects in Bhutan.

In addition to our sales and procurement services, we also offer technical support to ensure the successful implementation of your projects. Our experienced engineers are available to provide guidance on product selection, installation techniques, and troubleshooting. We understand the importance of timely and efficient support, and we are committed to helping you overcome any challenges you may face.

As a subsidiary of CNBM, one of the largest building materials companies in the world, we have access to a vast network of resources and expertise. This allows us to offer competitive prices and ensure the availability of high-quality materials. We are committed to delivering exceptional value to our customers and building long-term partnerships based on trust and reliability.

We invite you to experience the wonders of Bhutan while working with us. Whether you are visiting for business or pleasure, we can help you make the most of your time in this enchanting kingdom. From arranging cultural tours to providing recommendations for local attractions, our team is here to assist you in every way possible. Let us be your guide to the captivating allure of Bhutan while meeting your raw material needs. Contact us today to learn more about our services and how we can support your projects in Bhutan.

Hot Search

- Monolithic Refractories in Portugal

- Ceramic Fiber Products in Dominica

- Refractory Bricks in Lithuania

- Raw Materials For Refractory in Mauritania

- Raw Materials For Refractory in Georgia

- Raw Materials For Refractory in Sweden

- Raw Materials For Refractory in Netherlands

- Ceramic Fiber Products in Algeria

- Refractory Bricks in Denmark

- Raw Materials For Refractory in Jamaica