All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

What is the difference between ERW (Electric Resistance Welded) and LSAW (Longitudinal Submerged Arc Welded) steel pipe?

ERW (Electric Resistance Welded) steel pipe is manufactured by rolling a flat sheet of steel into a cylindrical shape and then welding the seam using an electric current. On the other hand, LSAW (Longitudinal Submerged Arc Welded) steel pipe involves submerging the steel plate into a welding arc and joining the edges longitudinally. The main difference lies in the welding process used, with ERW using electric resistance and LSAW using submerged arc welding. Additionally, LSAW pipes are typically used for larger diameter and thicker wall thickness applications compared to ERW pipes.

Can welded steel pipe be used for desalination plants?

Yes, welded steel pipe can be used for desalination plants. Welded steel pipes have excellent strength and durability, making them suitable for the high-pressure and corrosive conditions found in desalination plants. Additionally, welded steel pipes can be customized to meet specific project requirements, ensuring their compatibility with desalination plant systems.

How are welded steel pipes protected against abrasion?

Welded steel pipes are typically protected against abrasion through the application of protective coatings or linings. These coatings or linings act as a barrier between the steel surface and the surrounding environment, minimizing the impact of abrasion and preventing corrosion. Additionally, steel pipes can also be reinforced with wear-resistant materials or subjected to specialized surface treatments to enhance their resistance against abrasion.

What are the factors that affect the flow rate through a welded steel pipe?

The flow rate through a welded steel pipe is influenced by several factors, including the pipe diameter, length, roughness, and the fluid properties such as viscosity and density. Other factors that can impact the flow rate include the pressure difference across the pipe, the presence of any fittings or obstructions, and the overall system design.

What is the impact of elongation on the flexibility and ductility of welded steel pipe?

Elongation has a significant impact on the flexibility and ductility of welded steel pipe. When a steel pipe undergoes elongation, it means that it can stretch without breaking. This property is crucial in ensuring the flexibility of the pipe, allowing it to withstand bending and movement without fracturing. Additionally, elongation also enhances the ductility of the welded steel pipe, making it more resistant to deformation or cracking when subjected to external forces or pressure. Overall, a higher elongation percentage indicates better flexibility and ductility, making the welded steel pipe more reliable and suitable for various applications.

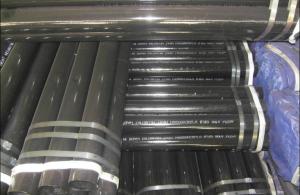

Wholesale Welded Steel Pipe from supplier in Bhutan

Our team is dedicated to delivering high-quality Welded Steel Pipe products to Bhutan. With our comprehensive services, we can assist you throughout the entire process, from sales to technical support. As a subsidiary of CNBM, a Fortune Global 500 company, we have the resources and expertise to provide you with convenient and efficient one-stop procurement solutions.

We understand the unique requirements of the Bhutan market and have tailored our offerings to meet your specific needs. Our extensive range of Welded Steel Pipe products ensures that we can cater to a variety of industries and applications. Whether you require pipes for construction, infrastructure, or industrial projects, we have the right solution for you.

In addition to our products, our years of experience in the Bhutan market enable us to offer valuable insights and expertise. We can provide guidance on product selection, technical specifications, and project planning to help you achieve success. Our team is committed to understanding your requirements and providing you with the best possible solutions.

We invite you to explore our wide selection of Welded Steel Pipe products and benefit from our comprehensive services. Contact us today to discuss your project and let us support you in achieving your goals in Bhutan.

We understand the unique requirements of the Bhutan market and have tailored our offerings to meet your specific needs. Our extensive range of Welded Steel Pipe products ensures that we can cater to a variety of industries and applications. Whether you require pipes for construction, infrastructure, or industrial projects, we have the right solution for you.

In addition to our products, our years of experience in the Bhutan market enable us to offer valuable insights and expertise. We can provide guidance on product selection, technical specifications, and project planning to help you achieve success. Our team is committed to understanding your requirements and providing you with the best possible solutions.

We invite you to explore our wide selection of Welded Steel Pipe products and benefit from our comprehensive services. Contact us today to discuss your project and let us support you in achieving your goals in Bhutan.