All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

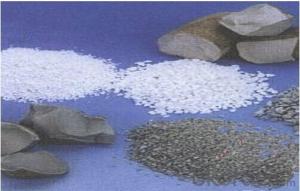

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How is fused cast chrome corundum utilized in the production of high-temperature refractories?

Fused cast chrome corundum is used in the production of high-temperature refractories due to its exceptional properties. Its high melting point and excellent corrosion resistance make it an ideal material for lining furnaces, kilns, and other high-temperature applications. The fused cast process ensures a dense and homogeneous structure, providing enhanced resistance to thermal shock and chemical attack. This material is crucial in maintaining the integrity and longevity of refractory linings, allowing them to withstand extreme temperatures and harsh environments in various industrial processes.

How do spinel and spinel-based materials work in refractories?

Spinel and spinel-based materials work in refractories by providing excellent thermal and chemical stability. They have high melting points, low thermal expansion, and good resistance to thermal shock, making them ideal for use in high-temperature applications. Additionally, spinel-based materials exhibit excellent corrosion resistance, making them suitable for harsh chemical environments. Due to these properties, spinel and spinel-based materials are widely used in the production of refractories to enhance their performance and extend their service life.

What are the advantages and limitations of using dolomite in refractories?

The advantages of using dolomite in refractories include its high melting point, excellent thermal shock resistance, and good resistance to corrosive environments. Dolomite also provides good dimensional stability and has a low coefficient of thermal expansion.

However, there are limitations to using dolomite in refractories. One limitation is its relatively low refractoriness compared to other materials, which may restrict its use in high-temperature applications. Dolomite also has a tendency to react with acidic materials, leading to the formation of undesirable compounds. Additionally, dolomite can exhibit a relatively high porosity, which may affect its mechanical strength and durability in certain applications.

What are the chemical properties of refractory raw materials?

The chemical properties of refractory raw materials refer to their resistance to chemical reactions and their ability to withstand high temperatures without undergoing significant changes in their structure or composition. These materials typically have high melting points, low reactivity with other substances, and the ability to retain their strength and stability at elevated temperatures.

Wholesale Raw Materials For Refractory from supplier in Netherlands

Our team of experts is highly knowledgeable about the refractory industry and can assist you in finding the right raw materials for your specific requirements. We understand the importance of timely and efficient delivery, and we work closely with our logistics partners to ensure that your orders are delivered on time.

When it comes to quotations, we strive to provide competitive prices without compromising on quality. Our strong relationship with our suppliers allows us to negotiate the best prices for our customers. We also offer technical support services to help you make informed decisions about the raw materials you need for your projects. Our team can provide guidance on product selection, usage, and troubleshooting.

As a subsidiary of CNBM, we have access to a wide range of resources and expertise. CNBM is a global leader in the building materials industry and has a strong presence in the Netherlands. This enables us to offer comprehensive procurement solutions, ensuring that you have access to high-quality raw materials at competitive prices.

We value our customers and strive to build long-term relationships based on trust and mutual benefit. Our goal is to provide exceptional customer service and exceed your expectations. Whether you are a small business or a large corporation, we are committed to meeting your needs and helping you achieve success in your projects.

Contact us today to discuss your raw material needs for refractory products in the Netherlands. We look forward to working with you and providing you with the best solutions for your projects.

When it comes to quotations, we strive to provide competitive prices without compromising on quality. Our strong relationship with our suppliers allows us to negotiate the best prices for our customers. We also offer technical support services to help you make informed decisions about the raw materials you need for your projects. Our team can provide guidance on product selection, usage, and troubleshooting.

As a subsidiary of CNBM, we have access to a wide range of resources and expertise. CNBM is a global leader in the building materials industry and has a strong presence in the Netherlands. This enables us to offer comprehensive procurement solutions, ensuring that you have access to high-quality raw materials at competitive prices.

We value our customers and strive to build long-term relationships based on trust and mutual benefit. Our goal is to provide exceptional customer service and exceed your expectations. Whether you are a small business or a large corporation, we are committed to meeting your needs and helping you achieve success in your projects.

Contact us today to discuss your raw material needs for refractory products in the Netherlands. We look forward to working with you and providing you with the best solutions for your projects.

Hot Search

- Monolithic Refractories in Iran

- Ceramic Fiber Products in Sri Lanka

- Refractory Bricks in Niue

- Raw Materials For Refractory in Mozambique

- Monolithic Refractories in Panama

- Raw Materials For Refractory in Albania

- Raw Materials For Refractory in Chile

- Monolithic Refractories in Tanzania

- Refractory Bricks in Philippines

- Monolithic Refractories in Burundi