All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

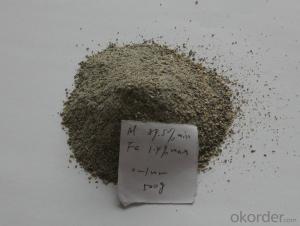

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

Q & A

How are silicon carbide-based castables applied in kilns and furnaces?

Silicon carbide-based castables are applied in kilns and furnaces by mixing them with water to form a slurry or a plastic consistency. This mixture is then poured or troweled into the desired area, such as the lining of the kiln or furnace. After application, the castable is allowed to dry and cure, forming a strong and durable lining capable of withstanding high temperatures and harsh conditions.

What are the benefits of using chromium oxide as a raw material in refractory production?

One of the main benefits of using chromium oxide as a raw material in refractory production is its high melting point. This property allows refractory materials to withstand extremely high temperatures without deforming or breaking down, making them ideal for use in furnaces and other high-heat applications. Additionally, chromium oxide exhibits excellent chemical stability, meaning it is resistant to corrosion and erosion by various chemicals and molten metals. This makes it a durable and long-lasting material for refractory linings. Furthermore, chromium oxide has good thermal conductivity, which helps in efficient heat transfer and distribution within refractory materials. Overall, the use of chromium oxide in refractory production offers enhanced heat resistance, chemical stability, and thermal conductivity, making it a valuable choice for industries requiring high-temperature applications.

How do raw materials affect the thermal expansion of refractory products?

Raw materials can greatly influence the thermal expansion of refractory products. Different raw materials have varying coefficients of thermal expansion, which determine how much a material expands or contracts when subjected to changes in temperature. By carefully selecting and controlling the raw materials used in the manufacturing process, it is possible to optimize the thermal expansion characteristics of refractory products to meet specific application requirements.

What are the advantages of using kyanite in refractory applications?

Kyanite offers several advantages in refractory applications. Firstly, it has a high refractoriness, meaning it can withstand high temperatures without losing its strength or shape. This makes it suitable for use in furnaces, kilns, and other high-temperature environments. Secondly, kyanite has low thermal conductivity, which helps in conserving energy by reducing heat loss. Additionally, its excellent resistance to thermal shock and chemical erosion makes it durable and long-lasting, resulting in reduced maintenance costs. Lastly, kyanite is abundantly available and cost-effective, making it a practical choice for various refractory applications.

Wholesale Raw Materials For Refractory from supplier in Kazakhstan

Our company understands the unique needs and challenges of the Kazakhstan market, and we have tailored our services to meet these specific requirements. We have established strong relationships with local suppliers and manufacturers, allowing us to offer competitive prices and ensure a reliable supply of high-quality raw materials for refractory products. Our experienced team is well-versed in the local regulations and industry standards, ensuring that our products meet all necessary requirements and certifications.

Customer satisfaction is our top priority, and we strive to provide exceptional service at every step of the process. Our dedicated sales team is available to provide personalized assistance, helping you find the right materials for your specific application and budget. We offer competitive quotations and flexible payment options to accommodate your needs. Furthermore, our technical support team is on hand to provide expert guidance and assistance throughout your project, ensuring that you achieve optimal results.

By choosing our company as your supplier of raw materials for refractory products in Kazakhstan, you can benefit from our extensive product range, competitive prices, reliable supply chain, and exceptional customer service. We are committed to helping you succeed in your projects and contributing to the growth and development of the refractory industry in Kazakhstan. Contact us today to discuss your requirements and discover how we can support your business.

Customer satisfaction is our top priority, and we strive to provide exceptional service at every step of the process. Our dedicated sales team is available to provide personalized assistance, helping you find the right materials for your specific application and budget. We offer competitive quotations and flexible payment options to accommodate your needs. Furthermore, our technical support team is on hand to provide expert guidance and assistance throughout your project, ensuring that you achieve optimal results.

By choosing our company as your supplier of raw materials for refractory products in Kazakhstan, you can benefit from our extensive product range, competitive prices, reliable supply chain, and exceptional customer service. We are committed to helping you succeed in your projects and contributing to the growth and development of the refractory industry in Kazakhstan. Contact us today to discuss your requirements and discover how we can support your business.

Hot Search

- Monolithic Refractories in Morocco

- Ceramic Fiber Products in Slovenia

- Refractory Bricks in Belgium

- Raw Materials For Refractory in Niger

- Monolithic Refractories in Brunei

- Refractory Bricks in Iceland

- Ceramic Fiber Products in Qatar

- Ceramic Fiber Products in Guatemala

- Raw Materials For Refractory in Poland

- Refractory Bricks in Angola