All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

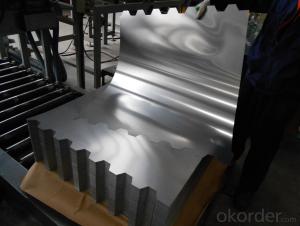

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How does the cold-rolling process affect the tensile strength of steel?

The cold-rolling process typically increases the tensile strength of steel. This is primarily due to the plastic deformation that occurs during the process, which aligns the steel's crystalline structure and increases its density. As a result, the steel's grain structure becomes more refined, leading to improved strength and hardness. Additionally, the cold-rolling process can also reduce the presence of impurities and defects in the steel, further enhancing its tensile strength.

How does the price of cold-rolled steel compare to other types of steel?

The price of cold-rolled steel is typically higher compared to other types of steel due to its superior finish, tighter tolerances, and enhanced mechanical properties.

How is the thickness of cold-rolled steel sheets measured and maintained within tolerance?

The thickness of cold-rolled steel sheets is typically measured using a non-destructive testing method called eddy current testing. This technique involves passing an alternating current through a coil, which generates a magnetic field. As the steel sheet passes through the coil, the magnetic field induces eddy currents within the metal. The interactions between the eddy currents and the magnetic field are then measured, allowing for the determination of the sheet's thickness.

To maintain the thickness within tolerance, several factors are considered. First, the manufacturing process of cold-rolled steel sheets involves precise control of the rolling mill parameters, such as speed, pressure, and temperature, which directly affect the final thickness. Continuous monitoring and adjustment of these parameters help ensure consistency in the thickness.

Additionally, regular calibration and maintenance of the equipment used for measuring the thickness are crucial. This involves periodic verification against known standards to confirm the accuracy of the measuring devices. If any deviations are detected, adjustments or repairs are made to maintain the accuracy of the measurements.

Overall, a combination of precise manufacturing processes, continuous monitoring, and calibration of measurement equipment are employed to measure and maintain the thickness of cold-rolled steel sheets within specified tolerances.

Wholesale Cold Rolled Steel from supplier in Swaziland

Whether you are in the construction, automotive, or manufacturing industry, our Cold Rolled Steel products are specifically designed to meet your requirements. We understand the importance of quality and reliability in your projects, which is why we only source our steel from reputable manufacturers.

Our team of experts is dedicated to providing excellent customer service and support throughout the entire procurement process. From initial inquiries to final delivery, we are committed to ensuring your satisfaction. Our sales representatives are knowledgeable in the field of Cold Rolled Steel and can provide accurate quotations tailored to your specific needs.

In addition, we offer technical support to assist you in making informed decisions about the right Cold Rolled Steel products for your projects. Our team can provide guidance on material specifications, applications, and industry standards. We believe in building long-term partnerships with our clients, and our technical expertise sets us apart from other suppliers.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry connections. This allows us to offer competitive pricing and reliable supply chain management. We understand the importance of timely deliveries, and our logistics team works tirelessly to ensure your orders arrive on schedule.

Choosing us as your Cold Rolled Steel supplier in Swaziland means you can rely on our commitment to quality, expertise, and customer satisfaction. Contact us today to discuss your Cold Rolled Steel requirements and let us exceed your expectations.

Our team of experts is dedicated to providing excellent customer service and support throughout the entire procurement process. From initial inquiries to final delivery, we are committed to ensuring your satisfaction. Our sales representatives are knowledgeable in the field of Cold Rolled Steel and can provide accurate quotations tailored to your specific needs.

In addition, we offer technical support to assist you in making informed decisions about the right Cold Rolled Steel products for your projects. Our team can provide guidance on material specifications, applications, and industry standards. We believe in building long-term partnerships with our clients, and our technical expertise sets us apart from other suppliers.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to a vast network of resources and industry connections. This allows us to offer competitive pricing and reliable supply chain management. We understand the importance of timely deliveries, and our logistics team works tirelessly to ensure your orders arrive on schedule.

Choosing us as your Cold Rolled Steel supplier in Swaziland means you can rely on our commitment to quality, expertise, and customer satisfaction. Contact us today to discuss your Cold Rolled Steel requirements and let us exceed your expectations.