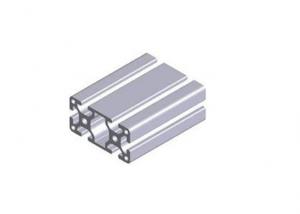

Aluminium Extrusion

Aluminium Extrusion Related Searches

Aluminum Extrusions Aluminum Extrusion Framing Aluminum Extrusion Shapes Aluminum Extrusion Plate Bosch Aluminum Extrusion Aluminum Extruded Tubing Extruded Aluminum Rail Aluminum Extrusion Stock Profile Extrusion Aluminum Extrusions Stock Shapes Extruded Aluminum Plate Aluminum Extrusion Shapes Stock Aluminum Extrusions Stock Extruded Aluminum Track Extruded Aluminum Beams Multi Plastics Extrusion Aluminium Coating American Thermoplastic Extrusion Company Extruded Aluminum Heatsink Extruded Aluminum Stock Shapes aluminum extrusion process flow chart Aluminum Corrosion Protection Extruded Aluminum Stock Plastic Extrusion Profiles Extruded Aluminum I Beam Cold Forming Aluminum Extruded Aluminum Frame Stock Misumi Extrusion Plastic Extrusion Melbourne Aluminum Embossing FoilAluminium Extrusion Supplier & Manufacturer from China

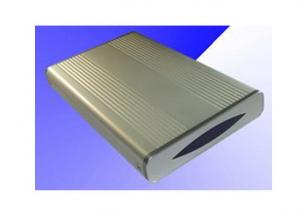

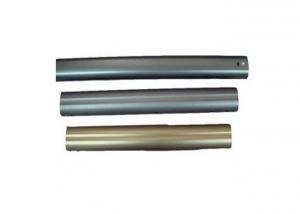

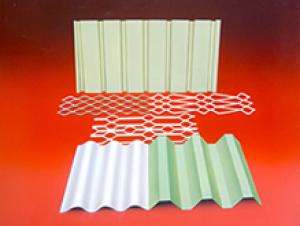

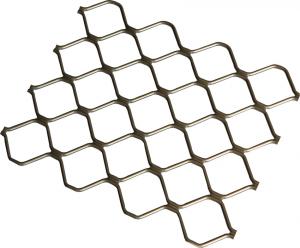

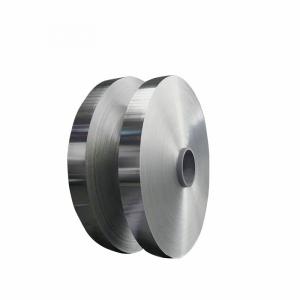

Aluminium extrusion is a process that involves shaping aluminium alloys into desired profiles by pushing them through a die under high pressure. This manufacturing technique results in a wide range of products, including window frames, door frames, and various structural components. The versatility of aluminium extrusion makes it an ideal material for various industries, such as construction, automotive, aerospace, and electronics.Aluminium extrusion products are widely used in numerous applications due to their strength, durability, and lightweight properties. These products can be found in various usage scenarios, such as in the construction of buildings, where they serve as structural supports and facades, or in transportation, where they are used for manufacturing vehicle components. Their corrosion resistance and recyclability also make them an environmentally friendly choice for many applications.

Okorder.com is a leading wholesale supplier of aluminium extrusion products, boasting a vast inventory to cater to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the aluminium extrusion products they offer meet the highest industry standards.