Aluminium Extrusion Profile for Windows and Doors China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. Specification of Aluminium Extrusion Profile for Windows and Doors China Supplier

Alloy | State | Tensile Strength δbMpa | Non-proportional Stretching Stress(δp0.2Mpa) | Stretching rate (δ%) | Pattern Thickness (mm) | HV | HW |

No Less Than | |||||||

6061 | T4/T6 | 180/265 | 110/245 | 16/8 | - | - | - |

6063 | T5/T6 | 160/205 | 110/180 | 8/8 | 0.8/- | 58/- | 8/- |

6063A | T5/T6 | 200,190/230,220 | 160,150/190,180 | 5,5/5,4 | 0.8,0.8/-,- | 65,65/-,- | 10,10/-,- |

2. Application of Aluminium Extrusion Profile for Windows and Doors China Supplier

wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors,windows…

3. Feature of Aluminium Extrusion Profile for Windows and Doors China Supplier

Surface Quality :

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Decoration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use,

Mochenical Property:

Chemical Composite and Mechanical Property

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

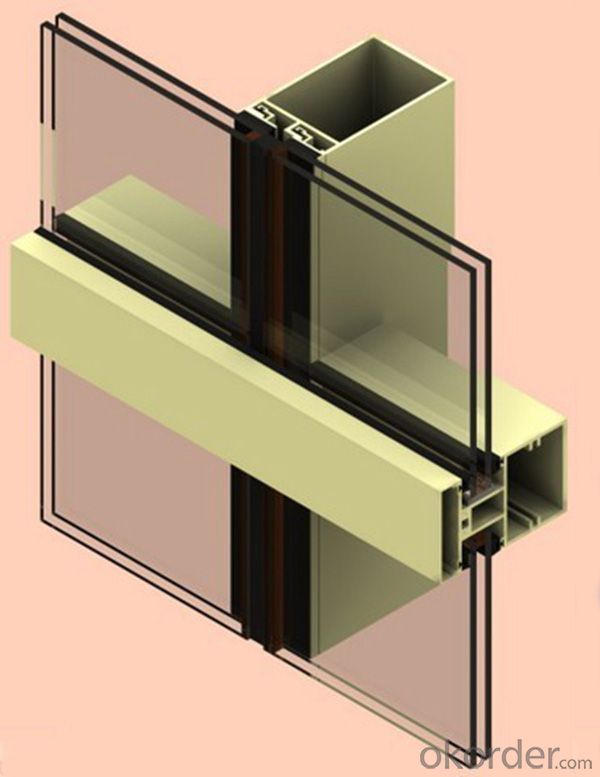

5. Image of Aluminium Extrusion Profile for Windows and Doors China Supplier

6. Package and shipping of Aluminium Extrusion Profile for Windows and Doors China Supplier

First, plastic cloth with drying agent inside; Second, Pearl Wool; Third, wooden cases with dry agent, fumigation wooden pallets, aluminum surface could cover blue PVC film

7. FAQ

Question 1: What is your MOQ?

We accept one ton per type for an order. But the detail we could negotiate.

Question 2: What is your normal terms of payment?

We always trade with you by T/T. But we also accept the L/C as you require.

Question 3: How many kinds of the surface treatment we can choose?

You could choose different color of powder coated. Anodized of black. matte silver, nature, champagne, bronze color. Mill finished. Wooden finished and printed.etc.

Question 4: Can you supply OEM services?

We offer OEM services for 17 years.

Question 5: How many days for opening the mould?

Normally about 10 days.According to the difficulty of your drawing.

Question 6: Can i choose the package what i want?

Yes, of course. We offer various kinds of package.e.g.PE foam. Shrink film. Wrapping paper.

But we would give you professional suggestion of package.

- Q: Are there any fire safety considerations for using aluminum profiles?

- Fire safety considerations must be taken into account when using aluminum profiles. Although aluminum itself is not combustible, it can still contribute to the spread and intensity of a fire if not adequately protected or used in suitable applications. One important factor to consider is applying fire-resistant coatings or treatments to the aluminum profiles. These coatings can enhance the profiles' fire resistance, reducing the likelihood of ignition and slowing down the flames' propagation. Fire-resistant coatings also play a crucial role in preventing the release of toxic gases or fumes during a fire, ensuring the safety of occupants. Furthermore, when incorporating aluminum profiles into structures, their proximity to potential fire sources or ignition points should be carefully evaluated. Implementing appropriate measures for fire compartmentation and separation is crucial to hinder the rapid spread of fire. Depending on the specific application and building codes, these measures may involve using fire-resistant barriers, firestops, or fire-rated walls. Moreover, selecting fire-resistant materials for components used in conjunction with aluminum profiles is of utmost importance. This includes opting for fire-rated glass, insulation materials, and sealants that can withstand high temperatures and impede the fire's advancement. Regular maintenance and inspection of aluminum profiles are also critical to ensure their fire safety. This involves thorough checks for damages, corrosion, or wear that could compromise their performance during a fire event. In conclusion, while aluminum profiles can be used safely in various applications, it is essential to consider fire safety measures and comply with building codes and regulations to minimize the risk of fire incidents. Seeking guidance from fire safety experts or consultants can provide valuable assistance in implementing appropriate fire safety considerations when utilizing aluminum profiles.

- Q: This question asks about the measures taken to guarantee that aluminum profiles adhere to safety standards during the installation process.

- <p>To ensure aluminum profiles meet safety standards during installation, follow these steps: 1) Use profiles certified to meet international safety standards such as ISO or ASTM. 2) Employ trained professionals for installation to avoid improper handling or assembly. 3) Regularly inspect the profiles for any signs of damage or wear before and after installation. 4) Adhere to the manufacturer's guidelines and specifications for installation to avoid structural weaknesses. 5) Use appropriate safety gear and equipment during the installation process to protect workers and the public. 6) Conduct load-bearing tests to confirm the structural integrity of the installed profiles. 7) Keep detailed records of all inspections, tests, and installations for future reference and compliance checks.</p>

- Q: How do you cut aluminum profiles?

- To cut aluminum profiles, there are a few methods you can use depending on the tools and equipment available to you. Here are three commonly used methods: 1. Power saw: A power saw, such as a miter saw or circular saw with a carbide-tipped blade specifically designed for cutting metal, is an effective way to cut aluminum profiles. Set the blade to the appropriate speed and angle for your desired cut, and slowly guide the saw through the profile, ensuring a smooth and accurate cut. 2. Hacksaw: If you don't have access to power tools, a hacksaw is an inexpensive and accessible option. Choose a fine-toothed blade designed for cutting metal and securely clamp the aluminum profile in a vice or workbench. Use long, steady strokes to cut through the profile, applying gentle pressure to maintain control and prevent the blade from binding. 3. Shearing: For thinner aluminum profiles, a manual shear can be used to make straight cuts. Place the profile into the shear, aligning the cutting edge with the desired cut line, and apply steady pressure to the handle, allowing the shear to slice through the aluminum. This method is ideal for cutting thinner profiles with precision and minimal risk of distortion. Regardless of the method you choose, it's important to wear appropriate safety equipment, such as safety glasses and gloves, to protect yourself from metal shavings and sharp edges. Additionally, always measure and mark your cut line accurately before beginning to ensure the desired result.

- Q: Can aluminum profiles be used in corrosive environments?

- Before making a decision, it is important to take certain factors into consideration when using aluminum profiles in corrosive environments. Aluminum naturally resists corrosion due to the formation of a protective oxide layer on its surface. This layer acts as a barrier, preventing further corrosion. However, in highly corrosive environments such as areas with high humidity, exposure to saltwater, or acidic conditions, the protective oxide layer may degrade over time. To enhance the resistance of aluminum profiles in corrosive environments, several measures can be taken. One option is to select an aluminum alloy with higher corrosion resistance, such as marine-grade or corrosion-resistant alloys that contain a higher percentage of alloying elements like copper or zinc. Furthermore, surface treatments like anodizing or powder coating can further enhance the corrosion resistance of aluminum profiles. Anodizing involves the creation of a thicker and more durable oxide layer on the aluminum surface, while powder coating provides an additional protective layer that acts as a barrier against corrosive agents. Regular maintenance and cleaning are also crucial for preserving the corrosion resistance of aluminum profiles in corrosive environments. This includes the removal of any accumulated dirt or debris that may contain corrosive substances. In conclusion, while aluminum profiles can be used in corrosive environments, it is vital to choose the appropriate alloy, consider surface treatments, and perform regular maintenance to ensure their long-term performance and durability.

- Q: What does "3030W" W mean for European standard industrial aluminum?

- This refers to the 3030 heavy aluminum profiles. General aluminum profile manufacturers will make a number of their own products, European standard 3030 series has a variety of specifications, such as Jing Teng aluminum European standard 3030R, referring to the European standard 3030 fan, 3030G refers to the 3030 GB profiles. In short, look at your own needs,

- Q: Are aluminum profiles suitable for conveyor systems?

- Yes, aluminum profiles are suitable for conveyor systems. They are lightweight, durable, and have high strength-to-weight ratio, making them ideal for building conveyor systems. Additionally, aluminum profiles offer flexibility in design and can be easily customized to meet specific conveyor requirements.

- Q: Can aluminum profiles be used for safety barriers or guardrails?

- Yes, aluminum profiles can be used for safety barriers or guardrails. Aluminum is a lightweight yet strong material that has excellent durability and corrosion resistance. These properties make it suitable for various applications, including safety barriers and guardrails. Aluminum profiles can be easily fabricated into different shapes and sizes, allowing for customization to meet specific requirements. They can be used in various settings such as industrial facilities, construction sites, roads, and walkways. Aluminum profiles can be designed to withstand impact and provide protection against falls or accidents. Additionally, aluminum profiles offer aesthetic appeal as they can be powder-coated in different colors to enhance visibility or blend with the surroundings. They are also low maintenance, requiring minimal upkeep compared to other materials. Aluminum profiles for safety barriers or guardrails are a cost-effective solution due to their long lifespan and recyclability. They are resistant to weather conditions, including UV rays and extreme temperatures, which ensures their performance and longevity. In summary, aluminum profiles are a suitable choice for safety barriers or guardrails due to their strength, durability, customization options, aesthetic appeal, low maintenance, and cost-effectiveness.

- Q: This question asks for the method to determine the amount of aluminum required for a construction project.

- <p>To calculate the weight of aluminum profiles needed for a building project, follow these steps: 1. Determine the length and cross-sectional area of each aluminum profile required. 2. Use the aluminum density, which is approximately 2.7 grams per cubic centimeter (g/cm鲁). 3. Multiply the volume (length 脳 cross-sectional area) by the density to get the weight of each profile. 4. Sum the weights of all profiles to get the total weight needed. Ensure to account for any additional material for joints, connections, and potential waste. It's also advisable to consult with an engineer or use specialized software for precise calculations tailored to your project's specific requirements.</p>

- Q: Can aluminum profiles be used for conveyor belts?

- Yes, aluminum profiles can be used for conveyor belts. Aluminum is a versatile and lightweight material that is commonly used in various industrial applications, including conveyor systems. Aluminum profiles offer several advantages for conveyor belts, such as high strength-to-weight ratio, corrosion resistance, and easy customization. These profiles can be easily fabricated into different shapes and sizes to match the specific requirements of the conveyor system. Additionally, aluminum profiles can be an economical choice as they require less maintenance and have a longer lifespan compared to other materials. Overall, aluminum profiles are a suitable option for conveyor belts due to their durability, versatility, and cost-effectiveness.

- Q: Can aluminum profiles be used in the construction of greenhouses?

- Yes, aluminum profiles can be used in the construction of greenhouses. Aluminum is a popular choice for greenhouse framing due to its durability, lightweight nature, and resistance to corrosion. It offers structural strength while allowing for maximum light transmission, which is essential for plant growth. Additionally, aluminum profiles are easy to assemble and maintain, making them an ideal material for constructing greenhouses.

Send your message to us

Aluminium Extrusion Profile for Windows and Doors China Supplier

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords