T-Slot Aluminum Extrusion Profiles 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

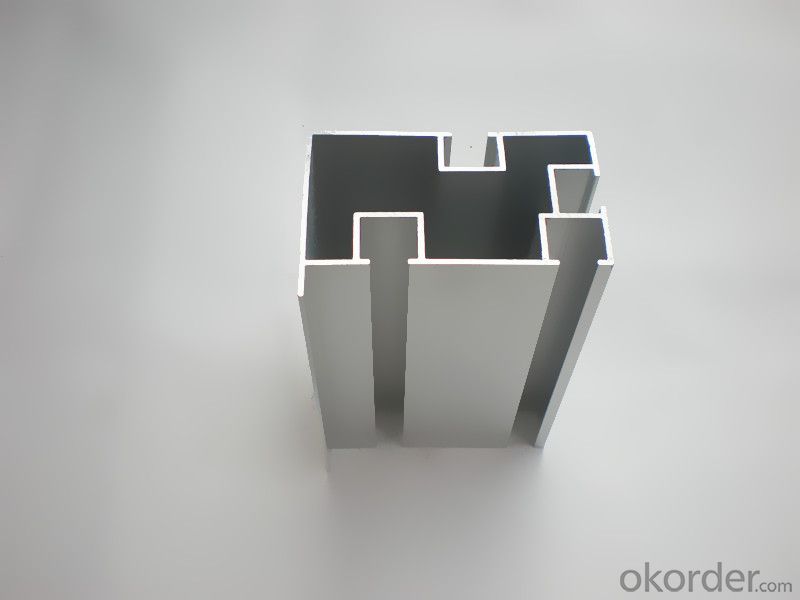

1.Structure of Aluminum Profile 6063 t5 Aluminum Extruded Profiles Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminum Profile 6063 t5 Aluminum Extruded Profiles :

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

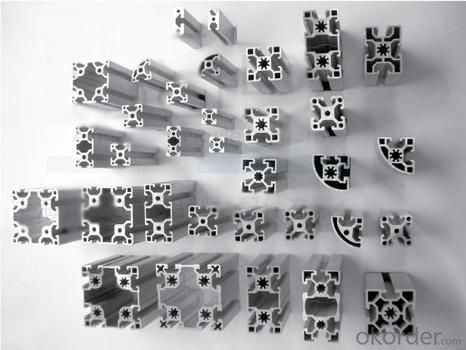

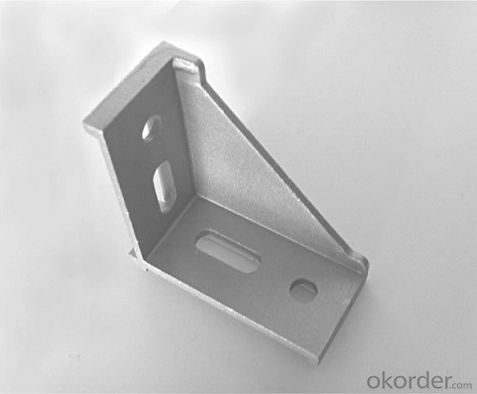

3.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Images:

4.Aluminum Profile 6063 t5 Aluminum Extruded Profiles Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: How do you prevent discoloration or fading of aluminum profiles?

- To prevent discoloration or fading of aluminum profiles, it is important to apply a protective coating or finish on the surface of the profiles. This can be done using methods such as anodizing, powder coating, or painting. These coatings act as a barrier, shielding the aluminum from exposure to UV rays, moisture, and other environmental factors that can cause discoloration and fading. Regular cleaning and maintenance also play a crucial role in preventing discoloration, as removing dirt, grime, and pollutants promptly can help preserve the appearance and integrity of the aluminum profiles.

- Q: What are the cost considerations for using aluminum profiles?

- Some cost considerations for using aluminum profiles include the initial cost of purchasing the profiles themselves, any additional costs for custom or specialized profiles, the cost of installation and assembly, maintenance costs, and potential future costs for repairs or replacements. Additionally, the cost of aluminum profiles may vary depending on the quality and thickness of the material used.

- Q: Is it possible to tailor aluminum profiles to fulfill particular design and aesthetic needs?

- <p>Yes, aluminum profiles can be customized to meet specific aesthetic requirements. Manufacturers offer a variety of finishes, colors, and surface treatments to enhance the visual appeal of aluminum profiles. Additionally, the profiles can be cut, bent, and shaped to fit unique design specifications. This customization allows for a high degree of flexibility in creating structures and designs that are both functional and visually appealing, making aluminum profiles suitable for a wide range of applications from architectural to industrial design.</p>

- Q: Can aluminum profiles be used in solar mounting systems?

- Yes, aluminum profiles can be used in solar mounting systems. Aluminum is a popular choice for solar mounting systems due to its lightweight, durability, and corrosion resistance properties. It is also easy to fabricate and install, making it an ideal material for constructing solar panel frames, rails, and supports. Additionally, aluminum profiles can be easily recycled, making them an environmentally friendly choice for solar mounting systems. Overall, aluminum profiles are a reliable and efficient option for solar mounting systems.

- Q: Are aluminum profiles compatible with other materials for construction purposes?

- <p>Yes, aluminum profiles can be used in combination with other materials in construction. They are often paired with steel, glass, and various plastics due to their lightweight, durability, and corrosion resistance. Aluminum's ability to be easily joined and its compatibility with different finishes make it a versatile choice for construction projects.</p>

- Q: What are the different surface finishing options available for aluminum profiles?

- Some of the different surface finishing options available for aluminum profiles include anodizing, powder coating, painting, polishing, and brushing. Each option offers a unique aesthetic and protective properties, allowing for customization and durability in various applications.

- Q: Excuse me, aluminum oxidation and electrophoresis have what different?

- Alumina:The substrate is used as an anode to be electrolyzed in an electrolyte, and a protective oxide film is formed on the surface of the substrate artificially so as to form an oxidized aluminum materialMain features of aluminium oxide material:1. It has strong wear resistance, weather resistance and corrosion resistance2, you can form a variety of colors on the substrate surface, the maximum to suit your requirements3, hardness is strong, suitable for all kinds of building, industrial material production

- Q: This question asks whether aluminum profiles can be recycled and if so, the process involved in recycling them.

- <p>Yes, aluminum profiles can be recycled. The recycling process typically involves collection, sorting, and shredding the aluminum profiles. After shredding, the material is melted in a furnace, which separates impurities and leaves behind pure aluminum. This molten aluminum can then be cast into new profiles or other products. The recycling of aluminum is energy-efficient and environmentally friendly, as it requires only 5% of the energy needed to produce aluminum from raw materials. This makes aluminum recycling a sustainable practice that helps conserve resources and reduce waste.</p>

- Q: For example, 80*80 square tube 2.0mm thick. Or 38*25 square tube, 0.8mm thick, how to calculate the rice weight? Please tell the specific formula, urgent

- Length (you want to count the number of meters) * width (square tube expansion size) * high (wall thickness) * density (you this square tube material density, aluminum alloy gold density is more complex, generally in 2650~2750Kg/m3)1m * (0.08 * 4) * * 2750kg/m 0.002=0.00064m fand fand =1.76KGThen you 80*80 wall thickness of 2 square tubes, one meter is 1.76 kilogramsWindows and doors exchange group (228021644) hope to help you!

- Q: Is it feasible to recycle aluminum profiles and what factors affect the recycling process?

- <p>Yes, aluminum profiles can be recycled easily. Aluminum is one of the most recycled materials globally due to its low melting point, which requires less energy for recycling compared to other metals. The recycling process involves melting the aluminum, which can be done at temperatures significantly lower than those needed for other metals. Additionally, aluminum retains its properties even after multiple recycling cycles, making it an ideal material for sustainable use. The recycling rate of aluminum is high, and it contributes to energy savings and reduced environmental impact. However, the ease of recycling can be affected by factors such as the presence of impurities, the complexity of the profile shapes, and the efficiency of collection systems.</p>

Send your message to us

T-Slot Aluminum Extrusion Profiles 6063 T5 Aluminum Extruded Profiles

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords