Extruded Aluminum Heatsink

Extruded Aluminum Heatsink Related Searches

Aluminum Extruded Tubing Extruded Aluminum Plate Extruded Aluminum Rail Aluminum Heatsink Stock Extruded Aluminum Beams Aluminum Extrusions Extruded Aluminum Track Extruded Aluminum Stock Aluminum Extrusion Plate Aluminium Extrusion Aluminum Heat Sink Plate Extruded Aluminum Stock Shapes Extruded Aluminum Frame Stock Aluminum Extrusion Framing Hot Rolled Aluminum Plate Aluminum Heater Plate Heating Aluminum Foil Heat Sink Aluminum Foil Extruded Aluminum T Slot Plate Extruded Aluminum I Beam Aluminum Foil Heat Exchanger Aluminum Heat Sink Stock Aluminum Hot Plate Heat Resistant Aluminium Tape High Temperature Aluminum Tape Heat Resistant Aluminum Foil Aluminum Extrusion Shapes Aluminum Plate Heater Hard Anodized Aluminum Plate Extruded Aluminum Fence StockExtruded Aluminum Heatsink Supplier & Manufacturer from China

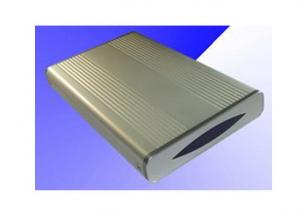

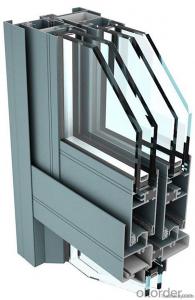

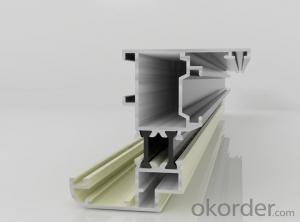

Extruded Aluminum Heatsink is a type of heat dissipation product that utilizes the thermal conductivity of aluminum to effectively manage and dissipate heat generated by electronic components. This product is designed with an extrusion process that creates a highly efficient heat dissipation structure, making it an ideal solution for various cooling applications.The Extruded Aluminum Heatsink is widely used in a variety of scenarios where heat management is crucial, such as in power electronics, LED lighting, and telecommunications equipment. Its lightweight and durable nature, combined with its ability to dissipate heat efficiently, makes it a popular choice for industries that require reliable cooling solutions. The extruded aluminum design not only enhances heat transfer but also provides a robust and long-lasting product that can withstand the rigors of demanding environments.

Okorder.com is a leading wholesale supplier of Extruded Aluminum Heatsink, offering a vast inventory of this product to cater to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Extruded Aluminum Heatsink meets the highest standards of performance and reliability. By partnering with Okorder.com, customers can benefit from a reliable source of supply, competitive pricing, and excellent service, making it the go-to platform for all Extruded Aluminum Heatsink requirements.

Hot Products