Extruded Aluminum Rail

Extruded Aluminum Rail Related Searches

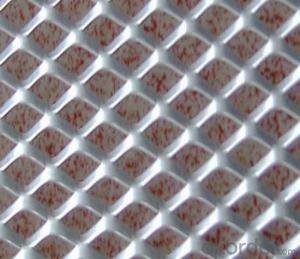

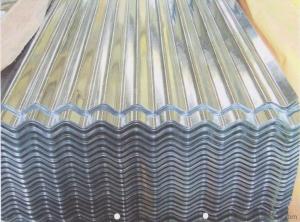

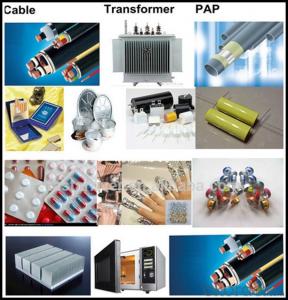

Extruded Aluminum Track Aluminum Extruded Tubing Extruded Aluminum Plate Extruded Aluminum Beams Aluminum Extrusions Aluminium Extrusion Extruded Aluminum Stock Extruded Aluminum Heatsink Aluminum Extrusion Framing Aluminum Extrusion Plate Extruded Aluminum Frame Stock Extruded Aluminum Stock Shapes Extruded Aluminum I Beam Extruded Aluminum Bar Stock Aluminum Extrusion Shapes Aluminum Strip Aluminum Wheels Aluminum Mill Aluminum Electrical Wiring Cold Forming Aluminum Reinforced Aluminum Tape Aluminum Foil Hot Rail Embossed Aluminum Coil Aluminum Custom Wheels Stainless Steel Aluminum Expanded Aluminum Foil Mesh Rolled Aluminum Plate Extruded Aluminum T Slot Plate Machined Aluminum Plate Aluminum Extrusion StockExtruded Aluminum Rail Supplier & Manufacturer from China

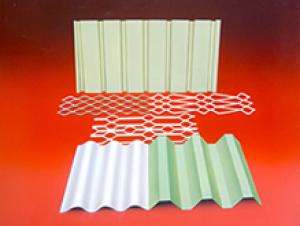

Extruded Aluminum Rail is a type of aluminum extrusion product that is widely used in various industries due to its durability, lightweight, and corrosion-resistant properties. These rails are often utilized in applications such as machinery and equipment framing, display systems, and structural support systems, making them an essential component in many manufacturing and construction projects. The versatility of extruded aluminum rails allows them to be tailored to specific requirements, ensuring that they can be used in a multitude of scenarios where strength, precision, and aesthetics are paramount.In various usage scenarios, extruded aluminum rails are chosen for their ability to provide a sturdy and reliable support structure. They are commonly found in commercial and residential settings, where they serve as a backbone for shelving, cabinetry, and other built-in fixtures. Additionally, these rails are popular in the automotive and aerospace industries, where their lightweight and robust nature contribute to improved fuel efficiency and overall performance. The demand for extruded aluminum rails has grown significantly, making it a popular choice among manufacturers and suppliers.

Okorder.com is a leading wholesale supplier of extruded aluminum rails, boasting a large inventory that caters to the diverse needs of various industries. As a reputable supplier, they ensure that their products meet the highest quality standards, providing customers with reliable and cost-effective solutions for their aluminum rail requirements. By offering a comprehensive range of extruded aluminum rails, Okorder.com has established itself as a go-to source for businesses and individuals seeking high-quality, customizable aluminum extrusion products.