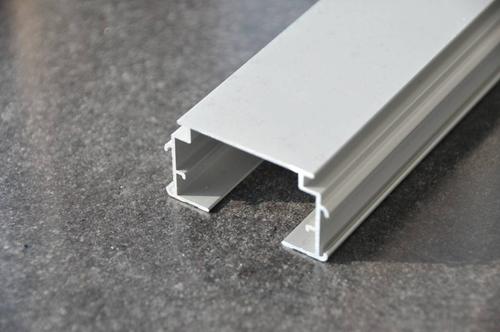

Aluminum Extrusions Profiles for Cable Trough

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminum Profile for Cable Trough

Usage:Cable trough

Surface:Anodizing,Powder coating, Electrophoresis

Alloy:6063

Size:according to customer’s requirement

Advantage:Durability, good corrosion resistance and lightweight

Package:Normal paper package and soft plastic interleaving each profile to protect the surface. In case of any special package, additional packing cost will be charged.

product details | |

Material | Alloy:6063,6061,6060,6005,7005 |

State | Mainly T5/T6 |

Thickness | above 1.0mm;recommend 1.2mm and above,customized available |

Normal Anodizing thickness | 8-12 micro |

Normal power coating thinkness | 600-100 micro |

Tensile strength | ≥ 16 mpa |

Yield strength | ≥ 110 mpa |

Extensibility | ≥ 8% |

Hardness(HW) | ≥ 8 |

Surface Treatment | 1) Mill finish |

Length | 1m-7m,Customized is available |

Packing | Kraft paper, EPE Fram, Shrink film, Composite paper,etc |

Standard | QC:ISO, SGS |

Time of samlple | 10-18days,including making mould |

Deep precessing ability | Drill holes,stretch bneding,milling,welding,fabrication etc |

Order process | 1.drawing/colors/price confirmed |

Trade terms | FOB Qingdao, CIF or CFR to the appointed port. |

Payment terms | T/T ,L/C,etc |

MOQ | 1*20 FCL |

- Q: This question asks about the various dimensions and forms of aluminum profiles that are typically utilized in the construction of building frames.

- <p>Aluminum profiles used in building frames come in a variety of sizes and shapes to meet different structural requirements. Common profiles include rectangular tubes, square tubes, angles (L-profiles), channels, and tees. Sizes range from small (e.g., 10x10mm to 30x30mm) to large (e.g., 100x100mm to 200x200mm), with thicknesses varying from 1mm to 6mm or more. Shapes are tailored to specific applications; for example, I-beams and H-beams are used for their high strength-to-weight ratio. These profiles are chosen based on load-bearing needs, aesthetic preferences, and construction techniques.</p>

- Q: Are aluminum profiles recyclable and can they be used again in flooring applications?

- <p>Yes, aluminum profiles can be recycled and reused in flooring applications. Aluminum is a highly recyclable material, with recycling processes that retain its properties without loss in quality. This makes it an environmentally friendly choice for flooring as it reduces waste and conserves resources. Recycled aluminum can be used to create new profiles for flooring systems, maintaining strength and durability while offering a sustainable solution.</p>

- Q: What are the ten brands of aluminum alloy profiles?

- Top ten list of Chinese aluminum profiles Enterprises1 、 aluminum material(China Aluminum Group, China's top ten aluminum enterprises, central management of large state-owned enterprises)2 - Asia - South Asia(China famous trademark, China famous brand, China aluminum profile enterprise ten, Guangdong Asia Aluminum Factory Co., Ltd.)3, the United States and aluminum(A Well-Known Trademark in China, China brand, China aluminum enterprise ten, Guangdong Jianmei Aluminum Profile Factory Co., Ltd.)4, South South aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong south south Aluminum Industry Co., Ltd.)5, Zhong Wang aluminum(China famous brand, China famous brand, Liaoning famous brand product, China Zhong Wang Holdings Limited)6, Hing Fat aluminum(China brand, A Well-Known Trademark in China, China aluminum enterprise ten, Xingfa Aluminum Holdings Limited)7, pillars of aluminum(listed companies, Chinese famous brands, China's well-known trademarks, China's aluminum enterprises ten, Zhejiang pillars, new materials, Limited by Share Ltd)8 、 Nanshan aluminum material(China famous brand, China well-known trademark, ten aluminum profile enterprises in China, Shandong Nanshan aluminum & Limited by Share Ltd)9, the court aluminum profiles(China's well known trademark, China's top ten aluminum enterprises, Polytron Technologies Inc, Shanghai aluminum Fair)10, Albert aluminum(China famous brand, Guangdong famous brand, Guangdong famous brand product, Guangdong Weiye aluminium factory Co., Ltd.)

- Q: What is the difference between 6061-T6 and 6063-T6 in aluminum profile?

- For example, Si ingredients: 6061 is 0.4 - 0.8; 6063 is 0.2-0.6. iron ingredients: 6061 is 0.7; 6063 is 0.35., etc.

- Q: What are the weight limitations of aluminum profiles?

- The weight restrictions of aluminum profiles rely on various factors, including the profile's dimensions, shape, and structural soundness. Aluminum profiles are generally lightweight and possess a favorable strength-to-weight ratio, making them suitable for a wide array of uses. Nonetheless, the maximum weight capacity will differ based on the distinct profile design and intended purpose. Aluminum profiles usually have the ability to bear a considerable amount of weight, particularly when they are engineered and reinforced correctly. For straightforward structural uses, such as framing or support systems, aluminum profiles can withstand loads ranging from a few hundred pounds to several thousand pounds. Industries such as construction, automotive, aerospace, and manufacturing frequently employ these profiles. It is worth noting that the load-bearing capacity of aluminum profiles can be enhanced through various techniques, such as increasing the thickness or incorporating reinforcing elements like gussets or braces. These modifications aid in distributing the weight and enhancing the profile's overall strength. Furthermore, it is vital to consider other factors like the profile's length, the type of connection or fastening method employed, and the overall stability of the structure. These factors can impact the weight restrictions and overall structural integrity of the aluminum profiles. To determine the specific weight limitations of aluminum profiles for a specific application, it is advisable to consult with a structural engineer or refer to the technical specifications provided by the manufacturer.

- Q: Can aluminum profiles be used in the production of food processing equipment?

- Aluminum profiles are indeed applicable in the production of food processing equipment. They possess a number of advantages for this purpose due to their lightweight and versatile nature. Their non-toxic and non-corrosive properties make them an ideal option for use in food processing environments where hygiene is of utmost importance. Moreover, aluminum profiles can be effortlessly cleaned, exhibit high resistance to chemicals, and remain unaffected by moisture or humidity. In addition, aluminum serves as an efficient heat conductor, which is crucial for ensuring effective food processing. Furthermore, it boasts exceptional structural strength and can be easily fabricated to produce customized equipment. Overall, aluminum profiles are widely favored in the food processing industry owing to their enduring nature, versatility, and hygienic attributes.

- Q: Can Linqu aluminum profile factory have 100 home?

- Some of the largest Huajian aluminum industry in Linqu there is no doubt that there are a lot of good after scale manufacturers, such as Albert Wei Sheng Jian Zhonghao new east to east of Yangtze River following so little that it is not representative of the product but a superb collection of beautiful things, not in Linqu, most of the manufacturers is YISHION aluminum ingots as raw material, processing technology is advanced basically, can ensure the quality of products. Louzhu should mention the one hundred, because there is only a scale can reach 53 (news reports), the number of small scale is much larger than this number, so the one hundred aluminum manufacturers should be more than enough, thank you for adopting!

- Q: Are aluminum profiles suitable for solar panel frames?

- Yes, aluminum profiles are highly suitable for solar panel frames. Aluminum is lightweight, strong, and corrosion-resistant, making it an ideal material for constructing durable and long-lasting frames. Additionally, aluminum profiles can be easily customized to meet the specific requirements of solar panels, such as size and shape, while also providing excellent heat dissipation properties.

- Q: Can aluminum profiles be used in HVAC systems?

- Yes, aluminum profiles can be used in HVAC systems. Aluminum is a lightweight and durable material that is commonly used in various industries, including HVAC. It offers several advantages such as excellent thermal conductivity, corrosion resistance, and easy formability. Aluminum profiles are commonly used in HVAC systems for components such as ductwork, air vents, and heat exchangers. Ductwork made from aluminum profiles is lightweight, easy to install, and resistant to corrosion, making it a popular choice for HVAC installations. Aluminum air vents provide efficient airflow and can be easily adjusted to control the direction and volume of air. Aluminum heat exchangers are also widely used in HVAC systems. The excellent thermal conductivity of aluminum allows for efficient heat transfer, making it ideal for applications where heat exchange is necessary. Additionally, aluminum's corrosion resistance ensures the longevity and reliability of heat exchangers, even in harsh environments. Overall, aluminum profiles are a suitable choice for HVAC systems due to their lightweight nature, durability, thermal conductivity, and corrosion resistance. They contribute to the overall efficiency and performance of HVAC systems while ensuring long-lasting functionality.

- Q: How about the price of aluminum profile?

- Usually calculated by weight, or by weight according to the length of each metre.

Send your message to us

Aluminum Extrusions Profiles for Cable Trough

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords