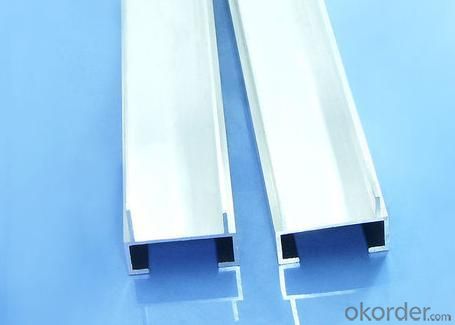

Aircraft Aluminum Extrusion Profiles for Industry

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of aluminium Profile for Industry

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of aluminium Profile for Industry

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of aluminium Profile for Industry

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

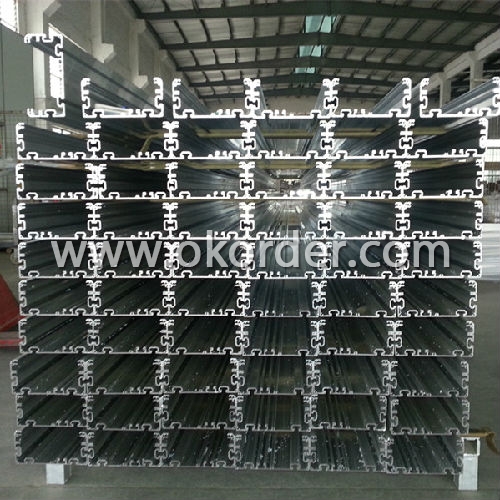

4 Production Flow of aluminium Profile for Industry

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: Are there any fire safety considerations for using aluminum profiles?

- Yes, there are fire safety considerations for using aluminum profiles. Aluminum has a low melting point and can ignite when exposed to high temperatures. Therefore, it is important to ensure that proper fire protection measures, such as fire-resistant coatings or barriers, are in place to minimize the risk of fire spreading through aluminum profiles. Additionally, regular maintenance and inspections should be conducted to identify any potential fire hazards and address them promptly.

- Q: Can aluminum profiles be used for signage or display purposes?

- Yes, aluminum profiles can definitely be used for signage or display purposes. Aluminum is a versatile and durable material that is commonly used in various industries, including signage and display. Aluminum profiles provide a strong framework for signs and displays, allowing for stability and longevity. The lightweight nature of aluminum makes it easy to handle and install, making it a popular choice for outdoor signage and indoor displays. Additionally, aluminum profiles can be easily customized and fabricated into various shapes and sizes, allowing for creativity and design flexibility. Aluminum profiles also offer excellent resistance to corrosion, ensuring that the signage or display remains in good condition even in outdoor or high-moisture environments. This makes them suitable for a wide range of applications, including storefront signs, directional signs, trade show displays, exhibition booths, and many more. Furthermore, aluminum profiles can be powder coated or anodized to provide a decorative finish, enhancing the visual appeal of the signage or display. This allows for branding and customization options, making the aluminum profiles a great choice for businesses looking to showcase their brand identity. Overall, aluminum profiles are a reliable and versatile choice for signage or display purposes. They offer strength, durability, design flexibility, and resistance to corrosion, making them suitable for a wide range of applications in various industries.

- Q: This question asks for various methods of producing aluminum profiles in a manner that is both efficient and cost-effective.

- <p>Efficient and cost-effective manufacturing of aluminum profiles can be achieved through several methods: 1) Using advanced extrusion technology, which is the primary method for shaping aluminum profiles, allows for high production rates and consistent quality. 2) Implementing automation in the production process to reduce labor costs and increase output. 3) Employing recycling techniques to use scrap aluminum, which lowers material costs and is environmentally friendly. 4) Optimizing the design of profiles to reduce material usage without compromising strength. 5) Utilizing energy-efficient equipment and processes to minimize energy consumption. 6) Regular maintenance and upgrading of machinery to ensure operational efficiency and reduce downtime. 7) Implementing just-in-time inventory management to minimize storage costs and reduce waste. 8) Continuous improvement through research and development to find new, more efficient methods of production.</p>

- Q: how to determine its value? After these scrap to foundry on the 30...Emergency: the scrap aluminum production enterprises how to conduct accounting treatment, how to determine its value? After the aluminum foundry to exchange into ingots, to pay the processing fee to enter

- The cost of scrap is usually included in the cost of the product. Therefore, the sale of scrap, only income, there is no cost. If the need for management, the establishment of "raw materials - Waste - XXX" can also be. Examples are as follows:1, March 5th workshop in accordance with product production needs. Lead aluminum 1000kg, the unit price is 23.4567 yuanBorrow: production cost - direct material 23456.70Credit: raw materials, -XX profiles, 1000kg 23456.702 and March 25th, the waste generated by the workshop 20kg into the waste warehouse, according to the market price of 5 yuan /kg valuation, according to retire the library for accounting treatmentBorrowing: production costs - direct material -100Credit: raw materials - Scrap - profiles -20kg, -1003 and March 27th, the stock 1200kg scrap sent to the foundry for aluminum ingot, ingot factory price 6 yuan /kgBy: accounts receivable - foundries 7200Credit: other business income + tax 72004, March 27th, scrap exchange aluminum ingot 1050kg, unit price 8 yuan /kg, separately pay processing fee 1200 yuanBorrow: raw material - aluminium ingot 10508400Credit: accounts receivable - foundries 7200Accounts payable - foundries 1200Payment of processing fees (differentials)By: accounts payable 1200Cash: 1200

- Q: Explain the various methods used to install aluminum profiles in construction projects.

- <p>There are several methods to install aluminum profiles in construction: 1. Bolting: Aluminum profiles can be secured with bolts and nuts, providing a strong and adjustable connection. 2. Welding: For permanent and rigid connections, aluminum profiles can be welded together. 3. Adhesive bonding: Using specialized adhesives, aluminum profiles can be bonded together for a secure fit. 4. Clipping: Some profiles come with clip-on connectors that allow for quick and easy assembly. 5. Screwing: Self-tapping screws can be used to join aluminum profiles, providing a strong hold without the need for pre-drilled holes. 6. Mortise and tenon: A traditional woodworking joint that can be adapted for aluminum profiles, creating a tight and secure fit. Each method has its advantages and is chosen based on the specific requirements of the construction project.</p>

- Q: What are the various energy-saving characteristics that can be incorporated into aluminum profiles?

- <p>Aluminum profiles can incorporate several energy-saving features to enhance thermal insulation and reduce energy consumption. These include: 1. Thermal breaks: Inserts that reduce heat transfer between the interior and exterior of a profile. 2. Multi-chamber designs: Multiple air chambers within the profile that act as insulators. 3. Low-E coatings: Reflective coatings that reduce heat transfer. 4. Insulating glass units: Double or triple glazed units with gas fills that provide superior insulation. 5. Passive solar design: Profiles designed to maximize heat gain in winter and minimize it in summer. 6. High-performance seals: Gaskets and seals that minimize air infiltration. 7. Aerodynamic shapes: Profiles that reduce air resistance and heat loss. These features can significantly contribute to energy efficiency in buildings.</p>

- Q: Are aluminum profiles suitable for use as exterior walls in residential buildings?

- <p>Yes, aluminum profiles can be used for exterior walls in residential buildings. They offer several advantages such as durability, low maintenance, and resistance to corrosion. Aluminum profiles are lightweight, which makes them easier to install compared to heavier materials. They also have good thermal conductivity, which can be managed with proper insulation to maintain energy efficiency. Additionally, aluminum can be powder-coated in various colors, offering design flexibility. However, it's important to ensure that the aluminum profiles meet building codes and standards for structural integrity and weather resistance.</p>

- Q: Can aluminum profiles be used in aerospace applications?

- Aluminum profiles find extensive use in aerospace applications. The aerospace industry has relied on aluminum for many years owing to its advantageous properties. Crucially, aluminum profiles are lightweight, a vital characteristic for aerospace applications. This lightweight property aids in reducing the overall weight of aircraft, leading to improved fuel efficiency and increased payload capacity. Additionally, aluminum profiles possess a high strength-to-weight ratio, enabling them to withstand the stress and forces encountered during flight. The corrosion-resistant nature of aluminum is also advantageous in the harsh and corrosive aerospace environment. Moreover, aluminum profiles offer ease of machining and can be formed into intricate shapes, providing greater design flexibility. The combination of lightweight, strength, corrosion resistance, and ease of fabrication establishes aluminum profiles as an exceptional choice for a range of aerospace applications, including aircraft frames, wings, fuselages, and structural components.

- Q: What are the advantages of using aluminum profiles in the telecommunications industry?

- There are several advantages of using aluminum profiles in the telecommunications industry. Firstly, aluminum profiles are lightweight yet strong, making them an ideal choice for constructing telecommunications infrastructure such as antenna towers and satellite dishes. Their lightweight nature allows for easy transportation and installation, reducing both time and cost. Secondly, aluminum profiles have excellent corrosion resistance properties. This is crucial in the telecommunications industry as it often involves exposure to harsh weather conditions and corrosive elements like saltwater. Aluminum profiles can withstand these conditions without deteriorating, ensuring the longevity and reliability of telecommunication equipment. Furthermore, aluminum profiles are highly adaptable and can be easily customized to meet specific design requirements. They can be extruded into various shapes and sizes, allowing for the creation of complex structures that can accommodate different telecommunications equipment. This versatility enables efficient integration of various components and facilitates the installation and maintenance processes. Additionally, aluminum profiles offer excellent thermal conductivity, which is essential in the telecommunications industry. As telecommunication equipment generates heat during operation, efficient heat dissipation is crucial to prevent overheating and equipment failure. Aluminum profiles effectively dissipate heat, ensuring optimal performance and longevity of telecommunication devices. Lastly, aluminum is a sustainable and eco-friendly material. It is 100% recyclable, meaning that old or damaged aluminum profiles can be recycled and repurposed into new products, reducing waste and environmental impact. The telecommunications industry can benefit from using aluminum profiles as part of their commitment to sustainability. In conclusion, the advantages of using aluminum profiles in the telecommunications industry include their lightweight yet strong nature, corrosion resistance, adaptability, thermal conductivity, and sustainability. These characteristics make aluminum profiles an excellent choice for constructing telecommunication infrastructure, ensuring reliable performance, and reducing environmental impact.

- Q: Is it feasible to recycle aluminum profiles and what factors affect the recycling process?

- <p>Yes, aluminum profiles can be recycled easily. Aluminum is one of the most recycled materials globally due to its low melting point, which requires less energy for recycling compared to other metals. The recycling process involves melting the aluminum, which can be done at temperatures significantly lower than those needed for other metals. Additionally, aluminum retains its properties even after multiple recycling cycles, making it an ideal material for sustainable use. The recycling rate of aluminum is high, and it contributes to energy savings and reduced environmental impact. However, the ease of recycling can be affected by factors such as the presence of impurities, the complexity of the profile shapes, and the efficiency of collection systems.</p>

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aircraft Aluminum Extrusion Profiles for Industry

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords