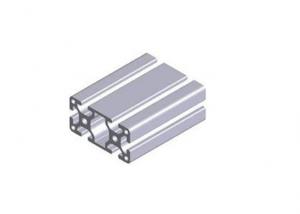

Aluminum Extrusion Stock

Aluminum Extrusion Stock Related Searches

Aluminum Extrusions Stock Aluminum Extrusion Shapes Stock Extruded Aluminum Stock Extruded Aluminum Bar Stock Extruded Aluminum Frame Stock Aluminum Extrusions Stock Shapes Aluminum Stock Extruded Aluminum Fence Stock Aluminum Engraving Stock Aluminum Machining Stock Aluminum Lathe Stock Aluminum Tubing Stock Anodized Aluminum Stock Aluminum Manufacturers Stock Aluminum Trim Stock Aluminum Box Stock Aluminum Price Stock Aluminum Metal Stock Aluminum Gun Stock Aluminum Frame Stock Stock Aluminum Extruded Aluminum Stock Shapes Tubular Aluminum Stock Aluminum Raw Stock Aluminum Commodity Stock Aluminum Spacer Stock Aluminum Chassis Stock Aluminum Rifle Stock Aluminum Stock Material Aluminum Pipe StockAluminum Extrusion Stock Supplier & Manufacturer from China

Aluminum Extrusion Stock encompasses a diverse range of aluminum profiles that are designed for various applications across different industries. These extruded aluminum products are known for their strength, durability, and lightweight properties, making them an ideal choice for numerous construction and manufacturing projects. The versatility of aluminum extrusion stock allows it to be used in a wide array of applications, from architectural structures and transportation systems to electronic devices and furniture components. This adaptability has made aluminum extrusion stock a popular choice among professionals and businesses alike.The usage scenarios for aluminum extrusion stock are vast, as it can be tailored to meet the specific requirements of each project. For instance, in the construction industry, aluminum extrusions can be used for window frames, door frames, and curtain walls, while in the transportation sector, they can be utilized for vehicle bodies, train carriages, and marine vessels. Additionally, aluminum extrusion stock is commonly employed in the manufacturing of electronic enclosures, solar panel frames, and various types of furniture. This extensive range of applications has led to a growing demand for high-quality aluminum extrusion stock.

Okorder.com is a reputable wholesale supplier of aluminum extrusion stock, boasting a large inventory that caters to the needs of various industries. As a leading distributor, Okorder.com ensures that customers have access to a comprehensive selection of aluminum extrusion profiles, all of which are manufactured to the highest standards. By offering a wide range of products and competitive pricing, Okorder.com has established itself as a reliable source for businesses and individuals seeking to purchase aluminum extrusion stock for their projects.

Hot Products