Aluminium Profile Extrusion Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Aluminium Profile Extrusion Windows and Doors Description:

Anodizing (also spelled anodising, particularly in the UK and Australia) is an electrolytic passivation process used to increase the thickness of the natural oxide layer on the surface of metal parts. Anodized aluminium surfaces, for example, are harder than aluminium but have low to moderate wear resistance that can be improved with increasing thickness or by applying suitable sealing substances.

2.Main Features of the Aluminium Profile Extrusion Windows and Doors:

High corrosion-resistance;

weather-resistance;

heat-resistance;

alkali-resistance and impact-resistance properties.

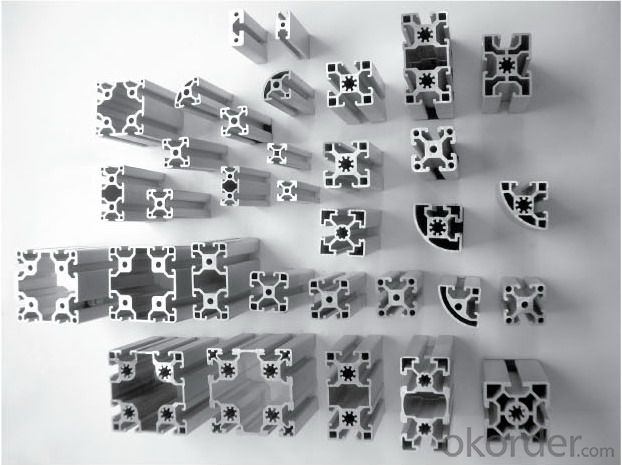

3.Aluminium Profile Extrusion Windows and Doors Images:

4.Aluminium Profile Extrusion Windows and Doors Specification:

1. Material: 6063,6061,6060,6005,6005A,etc.

2. Temper: T5 or T6

3. Finish: Mill finish, anodizing, powder coating, electrophoresis, wooden transfer or pvdf/carbon-flouride coated, polishing, brushing, sand blasting

4. Various colors: Silver, bronze, black, gold, blue, grey, champagne, bright, etc.

5. Machining: Cutting, punching, drilling, tapping, milling, bending, welding, CNC etc.

5.FAQ:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China, consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe, America and Japan. OEM casting and forging service available according to customer’s requirements.

②How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

- Q: Is it possible to use aluminum sheets as a material for flooring?

- <p>Yes, aluminum sheets can be used for flooring applications. They are known for their durability, resistance to corrosion, and ease of maintenance, making them suitable for various environments. Aluminum flooring is often used in commercial, industrial, and residential settings due to its strength and lightweight nature. It can be found in applications such as walkways, ramps, and as a covering for platforms. However, it's important to note that aluminum may not be the best choice for all flooring needs, especially where thermal insulation or a softer, warmer feel is desired.</p>

- Q: (1) Aluminum is malleable. (2) Aluminum reacts with sulfuric acid.(3) Aluminum conducts an electric current.(4)Aluminum has a density of 2.698 g/cm3 at STP.Explain why.

- oxygen supports combustion is the chemical one

- Q: Can aluminum sheet be painted?

- Yes, aluminum sheet can be painted. However, it is important to properly prepare the surface before painting to ensure that the paint adheres well and lasts longer. The process usually involves cleaning the aluminum sheet to remove any dirt, grease, or oxidation, followed by applying a primer to promote better adhesion. Once the primer is dry, you can then apply the paint of your choice. It is recommended to use a high-quality paint suitable for metal surfaces to achieve the best results. Additionally, if the aluminum sheet will be exposed to outdoor elements, it is advisable to use a paint that is specifically formulated for exterior use, in order to provide protection against weathering and corrosion.

- Q: Can aluminum sheets be used for balcony railings?

- Yes, aluminum sheets can be used for balcony railings. Aluminum is a lightweight and durable material that is commonly used for this purpose due to its resistance to rust and corrosion. Additionally, aluminum can be easily shaped and customized to meet specific design requirements, making it a popular choice for balcony railings.

- Q: I know aluminium forms a protective layer of aluminum oxide and hence water does not corrodes it easily.However, since the oxide is amphoteric, won't it react with acids and subsequently be dissolved?What is the main reason aluminium cans are used?

- Because of the aluminum chemical properties. Aluminum Oxide (Al2O3) is an extremely hard and compact material, so when the metal is exposed, it gets a very thin coat of Al2O3 that has a 9 hardness (only diamond is harder), that protects the rest of the metal from the atmosphere. Also, you should question if the phosphoric acid actually attacks aluminum, that is because that acid is found in Pepsi and coke..., BUT, as far as i know cans have a little plastic coat inside..., so the liquid does not get in touch with the aluminum.

- Q: What is the typical bend radius for aluminum sheets?

- The typical bend radius for aluminum sheets depends on various factors, such as the alloy, thickness, and temper of the sheet. However, a general guideline for the minimum bend radius for aluminum sheets is typically around 1 to 1.5 times the material thickness. For example, if you have a 1mm thick aluminum sheet, the minimum bend radius would be around 1 to 1.5mm. It is important to note that this is just a general guideline, and the specific bend radius may vary depending on the specific application and requirements. It is advisable to consult with a professional or reference material specifications for precise bend radius recommendations for a specific aluminum sheet.

- Q: If you're familiar with some of my previous questions, you'll know I have a thing for DC-3's, and I'd like to buy one and fix it up at some point in my life. I was looking at pictures on Google for my desktop background and saw several with shiny chrome/aluminum bodies. Well, first of all, is it chrome or polished aluminum? Second, would I be able to buy a DC-3 painted this God-awful forest green and put whatever it is (chrome/aluminum) on said plane? Or is it something that the plane has to be built with originally?

- Polished aluminum, get a couple heavy duty buffers and some for your friends and then buy stock in Flitz. You can also get it where you want it and paint it with clearcote to keep it a littl better, or what most do; paint it a light gray or silver color. You can strip it, but strip and paint is not cheap. Also, since the controls are fabric covered, they will never match the polished fuselage, that's why paint is better.

- Q: Can aluminum sheets be used for reflectors?

- Yes, aluminum sheets can be used for reflectors.

- Q: What are the different types of alloys used in aluminum sheet?

- Aluminum sheet incorporates a variety of alloys with distinct characteristics. Some of the most frequently employed alloys include: 1. The 3003 alloy is renowned for its exceptional corrosion resistance and finds utility in situations where moisture exposure is a concern. It is also highly malleable and can be easily welded, making it a popular choice for various structural components. 2. The 5052 alloy boasts remarkable corrosion resistance and excellent formability. It is commonly used in marine and automotive applications, as well as architectural elements. 3. The 6061 alloy provides unparalleled strength and is widely utilized in applications demanding high structural integrity. It is commonly found in the aerospace and marine industries, as well as in the construction of heavy-duty machinery. 4. The 7075 alloy is celebrated for its exceptional strength-to-weight ratio and is extensively employed in aerospace and defense applications. Furthermore, it is utilized in the manufacture of bicycle frames, rock climbing equipment, and other high-performance applications. 5. The 2024 alloy is renowned for its strength and outstanding fatigue resistance. It is frequently utilized in aerospace applications, as well as in the production of structural components and fasteners. These aforementioned examples merely scratch the surface of the multitude of alloys used in aluminum sheet. Each alloy possesses its own unique properties and advantages, rendering it suitable for specific industries and applications.

- Q: Can aluminum sheets be used in construction?

- Yes, aluminum sheets can be used in construction. They are commonly used for roofing, siding, and structural applications due to their lightweight, corrosion-resistant, and durable properties.

Send your message to us

Aluminium Profile Extrusion Windows and Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 3 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords