Adhesive Backed Aluminum Foil Sheets - Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

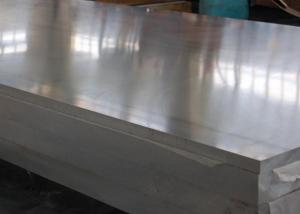

1 Specifications of Aluminum Sheet 1070

Alloy Number | AA1050 , AA1060 ,AA1070 ,AA1100 etc. |

Temper | H12, H14, H16, H18, H22, H24, H26, H32, HO, F |

Thickness | 0.1mm – 500mm |

Width | 10mm- 2200mm |

Standard | GB/T3880-2006, ASTM, ISO, EU standard |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Sheet 1070

Aluminum Plates is between 0.1 mm and 500mm in thickness and has a wide variety of uses in the construction industry including aluminium siding and roofing. Sheet is also used widely in construction, decoration, transport applications and other various industrial filed, such as automobile body panels, airframes, curtain walls and the hulls of boats etc.

CNBM produces aluminum plates which meets the highest standards in its own mill while save the cost. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier. CNBM aluminum complying with YS/T 429-2000(Chinese Industry Standard),GB/T 3880,EN485,ASTM B209.

3 Packaging & Delivery of Aluminum Sheet 1070

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers. Pallet weight: Max. 2.30 tons.

Shipment:the goods will be delivered in 40 days after getting the buyer's payment.

4 Production Flow of Aluminum Sheet 1070

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: Explain the distinctions between aluminum sheets and aluminum foil in terms of thickness, uses, and properties.

- <p>Aluminum sheets and aluminum foil are both made from aluminum but differ in thickness and applications. Aluminum sheets are thicker and more rigid, typically used for construction, manufacturing, and as a packaging material. They offer better strength and durability. Aluminum foil, on the other hand, is very thin and flexible, commonly used for food packaging, cooking, and insulation. It's lightweight and has excellent heat and light reflection properties. Aluminum sheets are often anodized or coated for additional properties, while foil is valued for its purity and malleability.</p>

- Q: Are aluminum sheets suitable for marine vessel construction?

- Indeed, marine vessel construction can make use of aluminum sheets. Aluminum, a material that is both lightweight and strong, offers excellent resistance to corrosion in marine environments. It is commonly utilized in the construction of various marine vessels, including boats, ships, and yachts. The use of aluminum sheets in marine vessel construction has a significant advantage in terms of its high strength-to-weight ratio. This allows for the creation of lighter vessels, which can lead to improved fuel efficiency, increased speed, and enhanced handling. Additionally, the lightweight nature of aluminum facilitates easier transportation and maneuverability during the construction process. Another notable benefit of utilizing aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally develops a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Moreover, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of intricate hull structures and interior components. Aluminum also possesses good thermal conductivity, which aids in regulating temperature within the interior spaces of marine vessels. While aluminum sheets offer numerous advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be implemented to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight nature, high strength-to-weight ratio, resistance to corrosion, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, it is crucial to take proper precautions to prevent galvanic corrosion when aluminum is used alongside other metals.

- Q: we have the mass of an aluminum sample =.47g, and the number of atoms in sample =107

- Look up the atomic mass of aluminum on your periodic table, multiply by 107, then divide by .47g?

- Q: Could induction heating fuenace be packaged with aluminum foil as insulation material?

- Aluminum foil can’t be used for heat retaining, it’s unsafe and hasn’t good efficiency. In this case, advice you use refractory cement to knot the coil and connect porcelain tube in the middle. It will Largely reduce the energy consumption produced by heat radiation.

- Q: How does the alloy composition affect the mechanical properties of aluminum sheet?

- The alloy composition of aluminum sheet plays a significant role in determining its mechanical properties. The inclusion of different elements in the alloy can influence its strength, hardness, ductility, and other characteristics. For instance, adding small amounts of copper or manganese can enhance the strength of aluminum, while magnesium can improve its corrosion resistance. Additionally, the size and distribution of alloying elements within the sheet can also impact its mechanical properties. Therefore, careful selection of alloy composition is crucial to achieve the desired mechanical performance of aluminum sheet.

- Q: What are the different packaging options available for aluminum sheets during transportation?

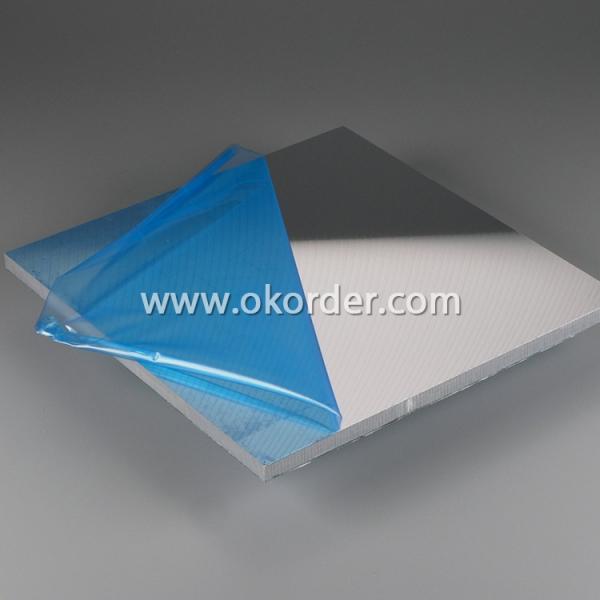

- There are several packaging options available for aluminum sheets during transportation to ensure their safety and prevent any damage. Some of the commonly used packaging options include: 1. Wooden Crates: Aluminum sheets can be packed in wooden crates, which provide excellent protection against impacts and rough handling. These crates are usually made of strong and durable wood and can be customized according to the size and weight of the sheets. 2. Cardboard Boxes: For smaller quantities or smaller-sized aluminum sheets, cardboard boxes are a popular packaging option. The sheets are carefully stacked and securely packed inside the boxes, which are then sealed to prevent any movement or damage during transportation. 3. Pallets: Aluminum sheets can also be packed on pallets, which are wooden or plastic platforms used for easy handling and transportation. The sheets are stacked and strapped onto the pallets to ensure stability and protection during shipping. 4. Stretch Wrap: Another option is to use stretch wrap to secure the aluminum sheets together. The sheets are tightly wrapped using a plastic film, which helps to keep them in place and protect them from scratches and other minor damages. 5. Protective Film: A common practice is to apply a protective film on the surface of aluminum sheets before packaging. This film acts as a barrier against moisture, dust, and scratches, providing an extra layer of protection during transportation. 6. Edge Protectors: To prevent any damage to the edges of the aluminum sheets, edge protectors can be used. These are typically made of plastic or cardboard and are placed on the edges to absorb any impacts and ensure the sheets remain intact. 7. Customized Packaging: Depending on the specific requirements of the aluminum sheets and the transportation method used, customized packaging solutions can be designed. This may include using foam inserts, dividers, or additional cushioning materials to provide maximum protection during transit. It is important to choose the appropriate packaging option based on the size, weight, and fragility of the aluminum sheets, as well as the mode of transportation and the distance they need to travel. Proper packaging plays a crucial role in preventing any damage and ensuring the sheets reach their destination in optimal condition.

- Q: What are the different methods of surface laminating aluminum sheets?

- There are several methods of surface laminating aluminum sheets, each offering unique benefits and suitable for different applications. Some of the most common methods include: 1. Adhesive bonding: This involves applying an adhesive layer between the aluminum sheet and the desired surface material. The adhesive is typically cured through heat or pressure, forming a strong bond. This method is versatile and can be used with various surface materials like wood, plastic, or glass. 2. Roll bonding: Also known as cladding or cold roll bonding, this method involves sandwiching the aluminum sheet between two other metal sheets and applying high pressure to create a solid bond. Roll bonding is commonly used in the production of composite materials, such as aluminum-clad steel sheets. 3. Thermal spraying: This process involves melting or heating aluminum powder and spraying it onto the sheet surface using a thermal spray gun. The molten aluminum solidifies upon contact, forming a durable coating. Thermal spraying is often used for corrosion protection or as a base layer for subsequent surface treatments. 4. Powder coating: In this method, a dry powder paint is applied to the surface of the aluminum sheet electrostatically. The sheet is then heated, causing the powder to melt and form a smooth, protective coating. Powder coating provides excellent durability, resistance to impact, and a wide range of color options. 5. Anodizing: Anodization is an electrochemical process that enhances the natural oxide layer on the surface of aluminum sheets. By immersing the sheet in an electrolytic bath and applying an electric current, a controlled oxide layer is formed, providing corrosion resistance, improved adhesion for paint or adhesive, and aesthetic finishes. 6. Lamination with protective films: A protective film can be applied to the surface of the aluminum sheet to protect it during transportation, handling, or processing. These films are typically made of plastic and offer temporary protection against scratches, abrasions, and dirt. These are just a few of the many methods available for surface laminating aluminum sheets. The choice of method depends on factors such as the desired properties, intended use, and the specific requirements of the application.

- Q: How are aluminum sheets manufactured?

- Aluminum sheets are manufactured through a process called rolling, where aluminum billets are heated and passed through a series of rolling mills to reduce their thickness. The billets are first heated to a specific temperature and then rolled multiple times, with each pass reducing the thickness of the sheet until the desired gauge is achieved. The process also involves annealing, where the sheets are heat-treated to improve their strength and flexibility. Finally, the sheets are cut to the desired length and width before being packaged for distribution.

- Q: How do you prevent discoloration of aluminum sheets?

- In order to avoid discoloration of aluminum sheets, there are a few steps that can be taken. First and foremost, it is crucial to regularly clean the aluminum sheets to eliminate any dirt or debris that may potentially cause discoloration. Utilize a mild detergent or a specialized aluminum cleaner, along with a soft cloth or sponge, to gently scrub the surface. It is advisable to refrain from using abrasive cleaners or scrubbing pads, as they have the potential to scratch the surface and increase the likelihood of discoloration. Secondly, it is essential to thoroughly rinse the sheets after cleaning to eradicate any residue from the cleaning products. Residual chemicals can react with the aluminum and result in discoloration over time. Another preventive measure entails applying a protective coating or sealant on the aluminum sheets. This can establish a barrier between the metal and the surrounding environment, thus preventing oxidation and discoloration. There are diverse types of protective coatings available, such as clear lacquers or anodizing treatments, which can enhance the durability and appearance of the aluminum sheets. Moreover, proper storage of the aluminum sheets is paramount to minimizing exposure to moisture, humidity, and extreme temperature fluctuations. Moisture can expedite the oxidation process and lead to discoloration. It is recommended to store the sheets in a dry and well-ventilated area, away from direct sunlight or sources of heat. Consistent maintenance is vital to prevent discoloration. Periodically inspect the aluminum sheets for any indications of discoloration or damage, and promptly address any issues that arise. By adhering to these preventive measures, the aesthetic appeal and longevity of aluminum sheets can be maintained.

- Q: what's the difference between aluminum sheet detergent and central air-condition detergent?

- Central air condition cleaning includes air-cooled condenser cleaning and water-cooling condenser cleaning, if it’s air-cooled condenser cleaning, you can use aluminum sheet detergent.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Adhesive Backed Aluminum Foil Sheets - Aluminum Coil

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords