Pvc Aluminum Trim Coil

Pvc Aluminum Trim Coil Related Searches

Pvc Coated Aluminum Trim Coil Pvc Aluminum Coil Alside Pvc Aluminum Trim Coil Poly Aluminum Trim Coil Trim Coil Aluminum Pvc Coated Aluminum Coil Vinyl Coated Aluminum Trim Coil Alcoa Aluminum Trim Coil Aluminum Vinyl Siding Trim Coil Colored Aluminum Trim Coil Best Aluminum Trim Coil Clay Aluminum Trim Coil Aluminum Siding Trim Coil Black Aluminum Trim Coil Painted Aluminum Trim Coil Installing Aluminum Trim Coil White Aluminum Trim Coil Mastic Aluminum Trim Coil Bending Aluminum Trim Coil Wood Grain Aluminum Trim Coil Amerimax Aluminum Trim Coil Painting Aluminum Trim Coil Aluminum Trim Coil Roll 24 Aluminum Trim Coil Textured Aluminum Trim Coil Bronze Aluminum Trim Coil Woodgrain Aluminum Trim Coil Alside Aluminum Trim Coil Napco Aluminum Trim Coil Spectra Aluminum Trim CoilPvc Aluminum Trim Coil Supplier & Manufacturer from China

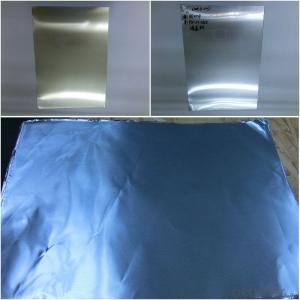

Pvc Aluminum Trim Coil is a versatile product that combines the durability of aluminum with the flexibility of PVC, making it an ideal choice for various construction and renovation projects. This composite material is designed to provide a long-lasting and weather-resistant solution for both interior and exterior applications, offering a range of benefits such as corrosion resistance, low maintenance, and a modern aesthetic.The Pvc Aluminum Trim Coil is widely used in a variety of settings, including residential and commercial buildings, where it serves multiple purposes. It can be employed as a decorative element for window and door frames, as a protective barrier for walls and ceilings, or as a structural component in the construction of outdoor decks and patios. Its adaptability allows it to be easily integrated into different architectural styles, making it a popular choice among contractors, architects, and homeowners alike.

Okorder.com is a leading wholesale supplier of Pvc Aluminum Trim Coil, boasting a substantial inventory that caters to the diverse needs of customers. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Pvc Aluminum Trim Coil they provide meets the highest industry standards. Their extensive stock allows for quick turnaround times and efficient delivery, making them a reliable source for businesses and individuals seeking to incorporate this innovative material into their projects.

Hot Products