Wholesale Aluminum Coil for Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1.Structure of Aluminum Coil for Casting:

Aluminum Master Casting Coil 6-8mm in alloys is used in the factories that produce aluminum coil from 0.2mm to 6mm by thickness. Hot rolled y cold rolled son available. The thickness of Aluminum Casting Coil for thin coil is about 6-8mm. You can choose the alloys as your using and we will do our best to meet your requests.

2.Main Features of the Aluminum Coil for Casting

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Low tolerance

• Strict quality control

• Well packaged

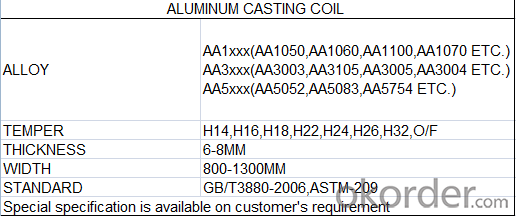

3. Aluminum Coil for Casting

4. Aluminum Coil for Casting

Cold Rolled

Hot rolled

5.FAQ

We have organized several common questions for our clients,may help you sincerely:

① What is the MOQ of Aluminum Coil for Casting

Usually the MOQ is 150 tons, but we also can make solution according to clients’ situation.

②How about your company?

A world class manufacturer & supplier of aluminum coil and alloy blanks. Aluminum production base is comprised of 18 aluminum annealers, 10 coil and foil mills, 4 continuous production lines, 2 hot rolling production line and 3 prepainted lines.

Export 5000 tons per month to Asia, America and Middle East. Always do the best for our clients.

③Can you guarantee the quality of the products?

We are responsible for the quality of materials in a reasonable period of time to get a long-term cooperation with clients and we are glad to arrange and coordinate any third party inspection for you.

④What is the delivery time after purchase?

15 day with normal specification after receiving client’s deposit or correct LC

- Q:Are aluminum coils suitable for beverage can manufacturing?

- Yes, aluminum coils are suitable for beverage can manufacturing. Aluminum is a preferred material for beverage cans due to its various advantageous properties. Firstly, aluminum is lightweight, which makes it easy to transport and handle. This is particularly important for the beverage industry, where large quantities of cans are produced and distributed. Additionally, aluminum is highly malleable, allowing it to be formed into the desired shape without losing its structural integrity. This makes it ideal for can manufacturing, as it can be easily shaped into a can's cylindrical form and withstand the pressure from carbonated beverages. Moreover, aluminum is a non-toxic material, ensuring that it does not contaminate the beverages stored in the cans. It also provides a barrier against light, oxygen, and moisture, which helps to preserve the taste and quality of the beverages. Furthermore, aluminum is recyclable, making it an environmentally friendly choice for can manufacturing. The recycling process for aluminum requires significantly less energy compared to producing new aluminum, making it a sustainable material option. Overall, the suitability of aluminum coils for beverage can manufacturing is evident due to its lightweight nature, malleability, non-toxicity, preservation properties, and recyclability.

- Q:what is aluminium toxic amount on a human's general physiological system? and what is the usual amount aluminium injested?thankyou

- It is estimated that the normal person takes in between 3 and 10 milligrams of aluminum per day. Aluminum is the most abundant metallic element produced by the earth. It can be absorbed into the body through the digestive tract, the lungs and the skin, and is also absorbed by and accumulates in the bodies tissues. Aluminum is found naturally in our air, water and soil. It is also used in the process of making cooking pots and pans, utensils and foil. Other items such as over the counter pain killers, anti-inflammatory products, and douche preparations can also contain aluminum. Aluminum is also an additive in most baking powders, is used in food processing, and is present in antiperspirants, toothpaste, dental amalgams, bleached flour, grated cheese, table salt, and beer, (especially when the beer is in aluminum cans). The biggest source of aluminum, however, comes from our municipal water supplies. Aluminum is excreted by the kidneys, therefore toxic amounts can impair kidney function. Aluminum can also accumulate in the brain causing seizures and reduced mental alertness. The brain is normally protected by a blood-brain barrier, which filters the blood before it reaches it. Elemental aluminum does not pass easily through this barrier, but certain compounds contained within aluminum, such as aluminum fluoride do. Interestingly, many municipal water supplies are treated with both aluminum sulfate and aluminum fluoride. These two chemicals can also combine easily in the blood. Aluminum fluoride is also poorly excreted in the urine.

- Q:What are the different types of aluminum coils?

- There are several different types of aluminum coils, including plain aluminum coils, painted aluminum coils, embossed aluminum coils, and coated aluminum coils. Each type has specific properties and uses, making them suitable for different applications in various industries.

- Q:What are the maximum and minimum coil weights available?

- The maximum and minimum coil weights available can vary depending on the specific type of coil being referred to. In the context of electrical coils, such as those used in transformers or motors, the maximum and minimum coil weights are determined by factors such as the size and material of the wire used, the number of turns in the coil, and the intended application. These coils can range from very small and lightweight to much larger and heavier, with weight limits typically specified by manufacturers. For example, a small coil might have a maximum weight of a few grams, while a larger coil could weigh several kilograms. It is important to consult the specifications provided by the manufacturer or supplier of the specific coil to determine the maximum and minimum coil weights available for a particular application.

- Q:What are the different coil handling options available for aluminum coils?

- Some of the different coil handling options available for aluminum coils include coil lifters, coil tongs, coil hooks, coil cradles, coil upenders, and coil cars. These options allow for safe and efficient handling of aluminum coils during transportation, storage, and processing.

- Q:What are the bending and forming capabilities of aluminum coils?

- Aluminum coils have excellent bending and forming capabilities due to their inherent flexibility and malleability. They can be easily bent, shaped, and formed into various complex shapes and designs without losing their structural integrity. This makes them highly versatile and suitable for a wide range of applications in industries such as construction, automotive, aerospace, and manufacturing.

- Q:What is the common color of aluminum coil membrane?

- The blue transparent membrane is the most common.

- Q:How are aluminum coils tested for flatness?

- Various methods are employed to test the flatness of aluminum coils, guaranteeing their compliance with the necessary standards. One commonly used approach involves the utilization of a straight edge. In this method, a lengthy and meticulously precise straight edge is placed on the coil's surface. Technicians then visually inspect for any discrepancies or gaps between the straight edge and the coil. The presence of such gaps indicates that the coil is not flat, necessitating further examination. Another technique utilized is the straight edge ruler method. Here, a ruler with a thin and flexible edge is applied to the surface of the coil. By applying gentle pressure, technicians can identify any areas where the ruler fails to fully make contact with the coil, indicating irregularities in its flatness. Advanced methods, including laser or optical techniques, are also employed to assess the flatness of aluminum coils. These methods employ laser beams or optical sensors to measure the surface profile of the coil. The collected data is then analyzed to determine if there are any deviations from the desired flatness. These sophisticated techniques provide precise and accurate results, enabling a more comprehensive evaluation of the coil's flatness. In conclusion, the testing of aluminum coils for flatness is of utmost importance in ensuring that they meet the required standards for a variety of applications. By utilizing a combination of visual inspection, straight edge techniques, and advanced laser or optical methods, manufacturers can guarantee that the coils are flat and devoid of any irregularities that could impact their performance.

- Q:How do aluminum coils contribute to energy-efficient lighting systems?

- Aluminum coils contribute to energy-efficient lighting systems by improving the heat dissipation process. When used in the construction of LED lighting fixtures, aluminum coils help in efficiently transferring heat away from the LED chips, preventing overheating and reducing energy consumption. This improved heat management ensures that the lighting system operates at optimal temperature, thereby extending the lifespan of the LEDs and enhancing overall energy efficiency.

- Q:I know when you stick weld aluminum you're more brazing than actually welding but i was just wondering about this, i want some electrodes just in case i need a temporary repair. Also what Amperage should i run it at,and what polarity?? my friend told me to run hotter than usual but hes only 14, and I dont know how reliable he is. Im 14 by the way also and have been welding for two years now and im always out running around the ranch doing small repairs. thanks ahead of time!

- you okorder /... heres some stuff you can buy online

1. Manufacturer Overview |

|

|---|---|

| Location | |

| Year Established | |

| Annual Output Value | |

| Main Markets | |

| Company Certifications | |

2. Manufacturer Certificates |

|

|---|---|

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period | |

3. Manufacturer Capability |

|

|---|---|

| a)Trade Capacity | |

| Nearest Port | |

| Export Percentage | |

| No.of Employees in Trade Department | |

| Language Spoken: | |

| b)Factory Information | |

| Factory Size: | |

| No. of Production Lines | |

| Contract Manufacturing | |

| Product Price Range | |

Send your message to us

Wholesale Aluminum Coil for Casting

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 100000 m.t./month

Offcanvas right

OKorder Service Pledge

OKorder Financial Service

Similar products

New products

Hot products

Hot Searches

Related keywords