Aluminum Corrugated Metal Roofing Sheets Toronto - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

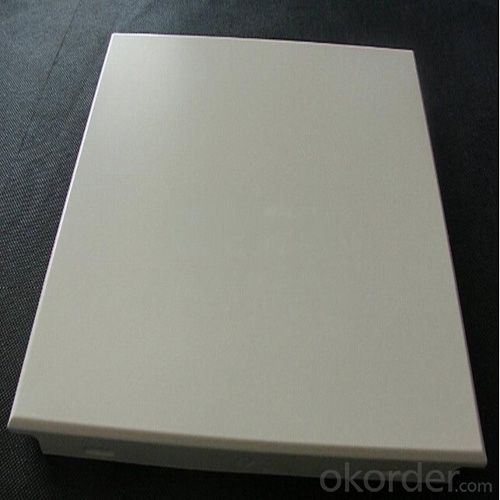

1.Structure of Aluminum Corrugated Metal Roofing Sheet Description:

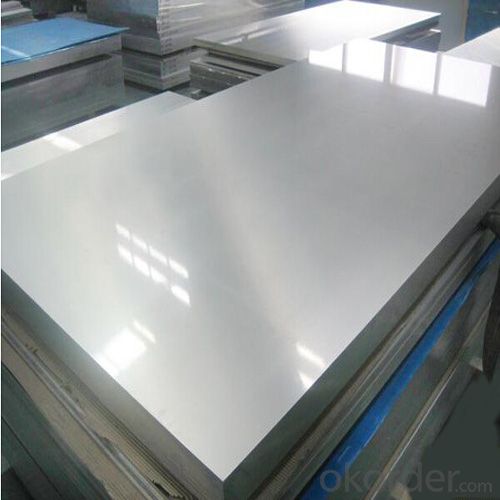

Aluminum Corrugated Metal Roofing Sheet are widely used for building use, decoration use, making cookware, busing making, shipping building, airplane making and so on。Sizes of aluminum sheet for decoration use: Thickness: 0.3mm~300mm Width: Under 2000mm ( Standard: 1000mm, 1219mm, 1500mm, 1540mm) Length: Under 10000mm. Products commonly used in signs, billboards, building exterior decoration, bus body, high factory wall decoration, kitchen sink, lamp, fan, electronic components, chemical apparatus, sheet processing, deep drawing or spinning hollow ware, welding parts, heat exchangers, Bell surface and plate, plates, kitchen utensils, accessories, safety equipment and other.

2.Main Features of Aluminum Corrugated Metal Roofing Sheet:

Good mechanical properties.

Easy processing, wearability.

Corrosion resistance

Resistance to oxidation.

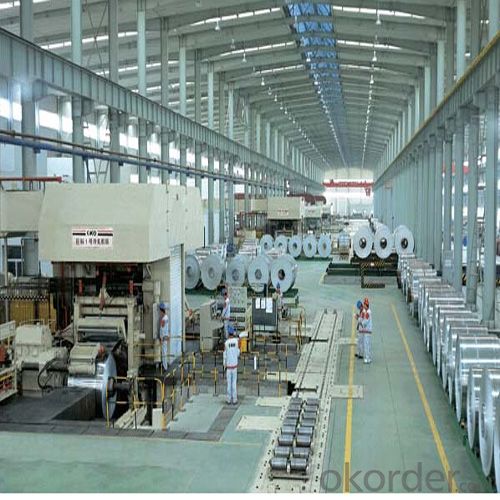

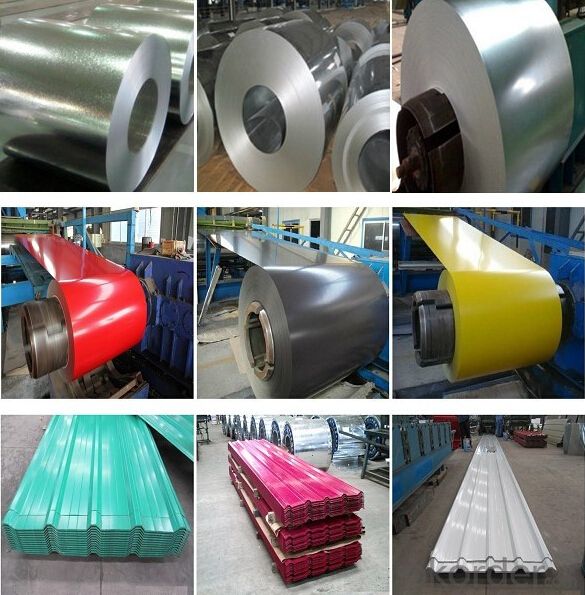

3. Aluminum Corrugated Metal Roofing Sheet Images:

4. Aluminum Sheets for Decoration Specification:

| Aluminium sheet | |||||

| Alloy No. | Thickness (mm) | Width (mm) | Length (mm) | Temper | |

| A1050,A1060, A1070,A1100 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18, H24,H26,etc | |

| 3A21,A3003,A3105,A3004 | 0.2-100 | 20-2200 | 20-8000 | O,H14,H18,H24,etc | |

| A5052 ,A5005,A5083,A5754 | 0.2-100 | 20-2200 | 20-8000 | O,H18,H24,H32,H34,H111,H112 ,etc | |

| A6061,A6082,A6063 | 0.2-200 | 20-2200 | 20-8000 | T4,T6, T651,etc | |

| A8011 | 0.2-100 | 20-2200 | 20-8000 | O,H12,H22,H14,H16,H18,H24,H26, etc | |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Is it possible to utilize aluminum sheets in the construction of high-rise buildings?

- <p>Yes, aluminum sheets can be used in high-rise buildings. They are valued for their lightweight, high strength, and resistance to corrosion. Aluminum is often used in curtain walls, window frames, and roofing due to its durability and recyclability. It also offers design flexibility and can be easily shaped and joined, making it suitable for modern architectural designs. However, it's important to ensure that the aluminum used meets the specific building codes and safety standards for high-rise construction.</p>

- Q: Are aluminum sheets resistant to vibration?

- Yes, aluminum sheets are generally resistant to vibration. Aluminum is a lightweight and flexible material that has good damping properties, meaning it can absorb and dissipate vibrations. Additionally, aluminum has a high strength-to-weight ratio, which allows it to retain its structural integrity even when subjected to vibrations. This makes aluminum sheets a popular choice in industries such as aerospace, automotive, and construction, where vibration resistance is important. However, it is worth noting that the specific resistance to vibration may vary depending on factors such as the thickness and alloy of the aluminum sheet, as well as the intensity and frequency of the vibrations.

- Q: Are the aluminum sheets suitable for manufacturing electronics components?

- Yes, aluminum sheets can be suitable for manufacturing electronics components. Aluminum is preferred for certain applications due to its lightweight, good thermal conductivity, and electrical conductivity properties. However, the suitability of aluminum sheets depends on the specific requirements and design of the electronics components being manufactured.

- Q: What are the potential health risks associated with handling aluminum sheets?

- <p>Working with aluminum sheets can pose certain health concerns, primarily due to inhalation of aluminum dust or fumes. Long-term exposure may lead to respiratory issues and potentially neurological problems. Aluminum dust can cause irritation to the eyes, nose, and throat. In some cases, it may contribute to the development of Alzheimer's disease, although this link is still debated. It's important to follow safety guidelines, such as using proper ventilation and wearing protective gear like masks and gloves, to minimize these risks.</p>

- Q: Can aluminum sheets be an alternative to plastic in certain applications?

- Yes, aluminum sheets can indeed be an alternative to plastic in certain applications. Aluminum is a highly versatile and sustainable material that offers several advantages over plastic, such as being more durable, resistant to UV rays, and having a longer lifespan. Additionally, aluminum is recyclable and can be reused indefinitely, making it a more environmentally friendly choice. However, the suitability of aluminum sheets as an alternative to plastic would depend on the specific application and requirements.

- Q: Are aluminum sheets suitable for chemical processing applications?

- Yes, aluminum sheets are suitable for chemical processing applications. Aluminum is a versatile and widely used material in various industries, including chemical processing. It possesses excellent corrosion resistance properties, making it highly suitable for applications involving exposure to chemicals and corrosive environments. Aluminum sheets are resistant to many acids and alkalis, including common chemicals such as sulfuric acid, hydrochloric acid, and sodium hydroxide. Aluminum's corrosion resistance is due to the formation of a thin, protective oxide layer on its surface, which acts as a barrier against chemical attacks. This oxide layer can quickly reform if damaged, providing continuous protection to the underlying metal. Furthermore, aluminum is lightweight, has high thermal conductivity, and can be easily formed into different shapes and sizes, making it a preferred choice for various chemical processing equipment and components. In chemical processing applications, aluminum sheets are commonly used for storage tanks, heat exchangers, piping systems, and other equipment that come into contact with chemicals. They can withstand high temperatures and pressures, making them suitable for various processing conditions. Additionally, aluminum is non-toxic, non-magnetic, and has excellent electrical conductivity, which can be advantageous in certain chemical processes. However, it is essential to consider the specific chemical environment and conditions when selecting aluminum sheets for chemical processing applications. Some aggressive chemicals, such as strong bases or highly oxidizing acids, may require additional protection or alternative materials. It is recommended to consult with experts or engineers familiar with the specific chemical processes and conditions to ensure the suitability of aluminum sheets for a particular application.

- Q: Are aluminum sheets suitable for medical equipment?

- Yes, aluminum sheets are suitable for medical equipment. Aluminum is a lightweight metal that offers excellent durability and corrosion resistance, making it a popular choice for medical equipment manufacturing. It is used in various medical devices such as surgical instruments, diagnostic equipment, and patient monitoring systems. Aluminum sheets are easy to shape and form, allowing for the fabrication of intricate medical equipment designs. Additionally, aluminum is non-toxic and non-magnetic, which are important properties in medical settings. Its ability to withstand sterilization processes such as autoclaving further enhances its suitability for medical equipment. Overall, aluminum sheets are a reliable and versatile material for the production of medical equipment.

- Q: What is aluminum curtain wall.

- Shell nosing edge sealing cap

- Q: Are 101 aluminum sheets suitable for automotive body panels?

- Yes, 101 aluminum sheets are suitable for automotive body panels. 101 aluminum is a high-strength alloy that offers good formability and corrosion resistance, making it an excellent choice for automotive applications. It is lightweight, which helps improve fuel efficiency and overall vehicle performance. Additionally, 101 aluminum has good dent resistance, ensuring that the body panels can withstand impacts and maintain their structural integrity. Overall, using 101 aluminum sheets for automotive body panels is a practical and effective choice.

- Q: What is the density of aluminum sheets?

- The density of aluminum sheets is subject to variation based on the particular alloy and thickness of the sheet. On average, aluminum sheets have a density ranging from 2.6 to 2.8 grams per cubic centimeter (g/cm³). It is worth mentioning that this figure may undergo slight modifications as a result of the precise manufacturing process and any additional coatings or treatments administered to the sheets.

Send your message to us

Aluminum Corrugated Metal Roofing Sheets Toronto - Best Price

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords