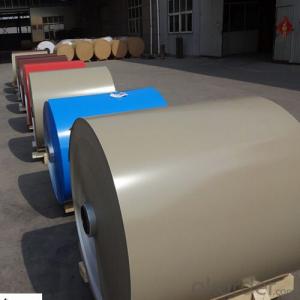

Large 5086 Aluminum Sheets and 6061 Aluminum Coils for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Specifications of 6061 Aluminium Coils

|

Alloy |

AA6061 |

|

Temper: |

T, H112, H12, H14, H16, H18, H22, H24, H26, H32,HO, F |

|

Thickness: |

0.10-500mm |

|

Width: |

10mm- 2200mm |

|

Standard: |

GB/T3880-2006, ASTM, ISO, EU standard |

|

Special Specification is available on customer’s requirement | |

2. Applications of 6061 Aluminium Coils

6061 Aluminium Coils have high / medium strength, good mechanical properties and good corrosion resistance. The alloy can be well anodized, so it is applied to various structural component requiring medium strength, high weldability and corrosion resistance, such as plate, tube, bar and section material used in truck, tower building, vessel, trolley, railway vehicle and furniture.

3. Package & Delivery of 6061 Aluminium Coils

Seaworthy package, water-proof paper wrapped inside, carton wrapped outside in wooden pallets by 20FCL or 40GP.

4. Production Flow of 6061 Aluminium Coils

The main producingprocedure of 6061 Aluminium Coils includes the following steps:

Rolling--Annealing--Slitting--Sawing, Cut-To-Length, Shearing

- Q: What are the advantages of using aluminum sheets compared to other materials?

- There are several advantages of using aluminum sheets compared to other materials. First, aluminum is lightweight, making it easier to handle and transport. Second, aluminum has corrosion resistance properties, ensuring durability and longevity. Third, aluminum sheets can be easily formed and molded into various shapes, allowing for versatility in applications. Additionally, aluminum is a good conductor of heat and electricity, making it suitable for use in industries such as aerospace and electrical engineering. Lastly, aluminum is recyclable, making it an environmentally friendly choice.

- Q: Can aluminum sheets be an alternative to wood in certain applications?

- Certainly, aluminum sheets can serve as a viable substitute for wood in specific applications. Aluminum boasts numerous advantages over wood, rendering it a favored choice across various industries. Primarily, aluminum exhibits exceptional durability and longevity due to its resistance to corrosion, rot, and pests. Consequently, it proves ideal for outdoor usage or areas with high moisture levels. Moreover, aluminum sheets are lightweight, facilitating easier handling and transportation in comparison to wood. Additionally, they possess a commendable strength-to-weight ratio, enabling them to withstand heavy loads while maintaining their structural integrity. Moreover, aluminum stands as a sustainable material, capable of indefinite recycling without compromising its properties. Conversely, wood necessitates the felling of trees, thereby carrying environmental implications. Aluminum sheets also offer a high degree of design flexibility, readily assuming complex structures through shaping, bending, and forming. This adaptability allows for innovative and creative applications. Furthermore, aluminum exhibits excellent thermal and electrical conductivity, rendering it suitable for scenarios where heat dissipation or electrical conductivity plays a crucial role. Nonetheless, it is crucial to acknowledge that wood retains its unique characteristics and benefits in certain applications. Wood imparts a warm and natural aesthetic that aluminum fails to replicate, making it a preferred choice in interior design or furniture manufacturing. Additionally, wood qualifies as a renewable resource and exhibits excellent insulation properties, proving advantageous in construction or insulation applications. Consequently, while aluminum sheets can serve as a fantastic substitute for wood in numerous instances, the ultimate choice hinges upon the specific requirements and desired outcomes of the application at hand.

- Q: Can 101 aluminum sheets be used in the production of nameplates or tags?

- Certainly! Nameplates or tags can be produced using 101 aluminum sheets. The durability, lightweight nature, and corrosion resistance of aluminum make it a popular material choice for such items. The 101 aluminum alloy, which is a commercially pure aluminum, offers excellent formability and workability. This makes it suitable for various manufacturing processes like stamping, engraving, or etching. It can be easily cut, shaped, and customized to create nameplates or tags with clear and precise markings. Moreover, aluminum's ability to withstand harsh environments and its appealing appearance make it preferred across industries like automotive, aerospace, electronics, and signage. Hence, 101 aluminum sheets are a suitable material for producing nameplates or tags.

- Q: does aluminum sheet has a function of magnetism isolating?

- yes.

- Q: We just bought a house with aluminum wiring and we knew about it in the inspection report, but everyone kept telling us it's no big deal. There was so much going on and I didn't look into it myself and now I just surfed the web on it and I am filled with anxiety! Please help! Did we make a huge mistake? How common are the dangers? Also, my insurance company didn't ask me about wiring, but some sites said that they don't cover aluminum wiring. Should I ask them? I am so overwhelmed and scared. I do not want a fire for my family!

- All of these answers are good. There is a concern. I would suggest that if there is a question of security -- that you slip ( or get an electrician) to slip each switch and outlet out of the wiring box and tighten the connections. As for the racoons, there are simple and pretty much low cost (under 30 bucks, voltage sensors at your local electrical supply, and maybe at Home-Depot. These really nice devices sense the presence of AC electricity in the wall, even locating the actual point where the electricity stops at a break! This is a do-it=yourself project.

- Q: Aluminum or steel bike frame cost more???...which one cost the most usually???

- Must add my 2 cents... Steel is not common at all anymore. Far less than 10% around my area, Michigan. I think that is true anywhere in the US anyway. I see far more full carbon than steel with alum being the easily the most common. Steel is a little heavier and compliant than alum. Any material can make a stiff frame if designed and built well. Steel by it's nature dampens vibration more than alum. I agree with mr g, it's an image to be projected. Steel = old school. I don't know why so much posing goes on in the road bike world. To actually answer the question: Both can be very costly. If we're talking about quality road frames, Alum would usually be cheaper. I would say it's a matter of production quantities. There are tons of alum frames out there and only a hand full of steel. Quality steel is a niche market now.

- Q: Does exposure to weather conditions have an impact on the durability and integrity of aluminum sheets?

- <p>Aluminum sheets are generally resistant to weathering, thanks to a protective oxide layer that forms on the surface when exposed to air. This layer prevents further oxidation and corrosion, making aluminum durable even in harsh weather conditions. However, the rate of weathering can be influenced by factors such as pollution, temperature fluctuations, and the presence of aggressive chemicals. While aluminum maintains its structural integrity well, it may experience some surface changes like patina formation over time, but these are mostly cosmetic and do not compromise the material's performance significantly.</p>

- Q: is there any kind of deoderant, other than those crystals that smell, that don't have aluminum in it?

- yes, just look for the word 'deodorant' instead of 'anti-perspirent'. I understand you may be concerned about the aluminum causing harm - however, it is the only way to stay 'dry'. The others allow you to sweat, and just cover up the odor.

- Q: Can the aluminum sheets be used for manufacturing chemical reaction vessels?

- Yes, aluminum sheets can be used for manufacturing chemical reaction vessels.

- Q: How does the thickness of aluminum sheet affect its strength?

- The strength of an aluminum sheet is directly influenced by its thickness. Generally, a thicker aluminum sheet will possess greater strength compared to a thinner one. This correlation arises from the fact that the thickness of the sheet determines the quantity of material present, ultimately impacting its ability to endure external forces or loads. Typically, the strength of a material is measured based on its capacity to withstand stress without deforming or failing. Thicker aluminum sheets have a larger volume of material, resulting in an increased number of atoms and bonds to counteract forces. Consequently, these sheets exhibit a heightened resistance to deformation or failure, thus rendering them stronger. Furthermore, thicker aluminum sheets boast a higher load-bearing capacity. Consequently, they can endure heavier loads or higher pressures without distorting or failing. The augmented thickness allows for a greater distribution of the load, thereby reducing the stress placed on individual atoms and bonds within the sheet. Nevertheless, it is crucial to acknowledge that there exists a limit to the thickness at which the strength of an aluminum sheet reaches a plateau. Once this threshold is surpassed, further increasing the thickness may not yield significant improvements in strength. This limitation arises from the influence of other material properties of aluminum, such as its crystal structure and grain boundaries, which also contribute to determining its strength. To conclude, the strength of an aluminum sheet is directly linked to its thickness. Thicker sheets possess more material, enabling them to effectively resist deformation or failure under stress. Furthermore, their increased thickness allows them to support heavier loads or endure higher pressures. However, it is important to recognize that there is a limit to the thickness at which the strength plateaus, as other material properties also come into play.

1. Manufacturer Overview

| Location | Henan,China |

| Year Established | 2002 |

| Annual Output Value | Above US$200 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Shanghai |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Large 5086 Aluminum Sheets and 6061 Aluminum Coils for Sale

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 3 Tons m.t.

- Supply Capability:

- 10000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords