5052 Aluminum Sheets for Sale - Direct Casting Aluminium Coils for Secondary Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

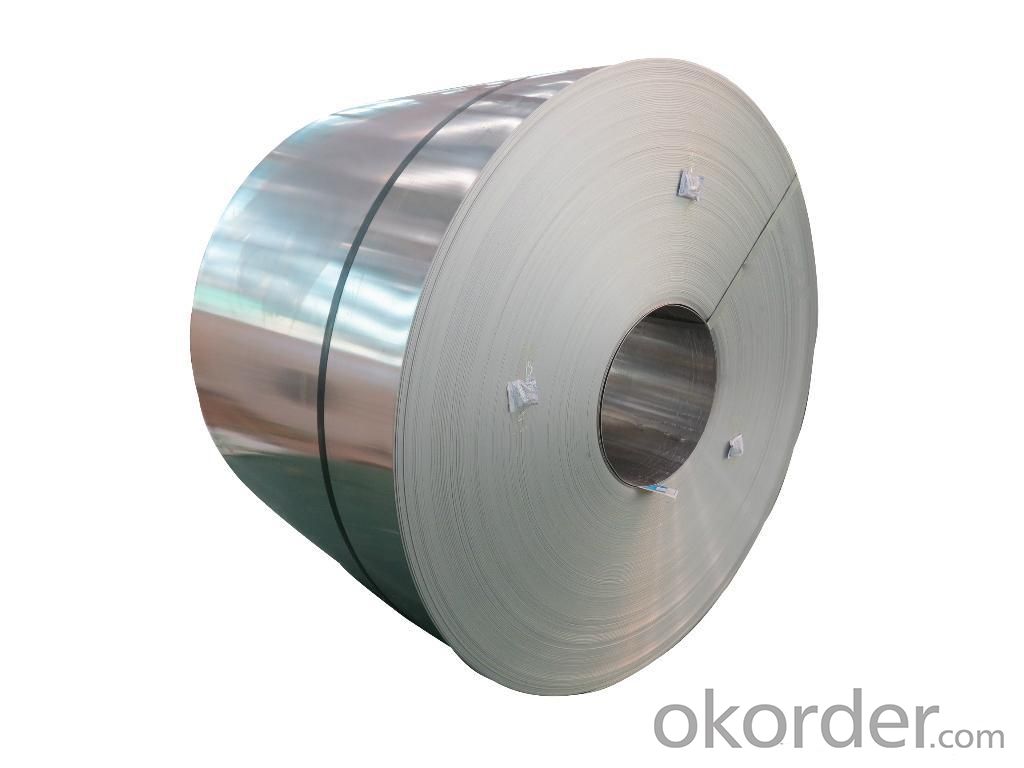

1.Structure of Direct Casting Aluminium Coils for Secondary Rolling

Direct Casting Aluminium Coils for Secondary Rolling in Coil is one semi-finished aluminium material. This strip can be rolled down to aluminium coil,sheet,circle ect. The alloy AA1050 is widly used in building, industry ect. Its weight is much lower than steel. So many customers choosed aluminium material instead of steel.

2. Main features of Direct Casting Aluminium Coils for Secondary Rolling

a.Competitive price---We have our own mills and can produce mill finished aluminium coils, so we can control the production cost better.

b.Professional after-sale service---We have more than 15 years exportation experience and you need not worry about the exporation problems.

c.Fast delivery time---We can control the delivery time within 35 days.

3. Image

4. Product Specification

| ALLOY | TEMPER | THICKNESS | WIDTH | WEIGHT |

| AA5052 | H14 | 3MM-8MM | 1200MM-1800MM | 5-6 TONS |

5.FAQ:

What is the quality standard?

---Usually our standard is GB3880-2006

What is the largest width?

---It is 2300mm

What is the MOQ?

---Usually we can accept 80 tons.

- Q: why could aluminum pot be repaired by knocking the aluminum sheet into the pot but not being bonded by glue?

- the oxidation rate of aluminum's surface is very quick, so we cann't use the method of tin welding, and the cost of argon arc welding is very high,so aluminum pot's repair usually uses riveting. aluminum has low hardness and good ductility, so it can be repaired by tightly knocking, without the bonding of glue. general glue will decomposed in open fire, if we bond pot by glue, the pot after repair won't be able to endure high temperature.

- Q: Can aluminum sheets be used for decorative or architectural purposes?

- Yes, aluminum sheets can be used for decorative or architectural purposes. Aluminum is a versatile material that can be easily manipulated into different shapes and forms, making it ideal for various architectural applications. It is commonly used for exterior cladding, roofing, window frames, and facades, providing a sleek and modern aesthetic to buildings. Aluminum sheets can also be used for decorative purposes, such as wall panels, art installations, signage, and furniture. The lightweight and durable nature of aluminum make it a popular choice for architects and designers looking to create visually appealing and functional structures. Additionally, aluminum is resistant to corrosion, making it suitable for both indoor and outdoor applications.

- Q: What's the maximum size of 3 mm thick aluminum sheet?

- To see what is your production process requirements? If it is hot extrusion, the width of the largest flatness requirements under the condition of low at about 300mm. If the processing technology of aluminum strip is hard to say, to see the production capacity of the equipment (the size and size is the maximum size of the majority in the 1.2) to 1.5 meters wide, the length of one hundred meters above

- Q: How do I prevent corrosion on aluminum sheets?

- To prevent corrosion on aluminum sheets, there are a few steps you can take: 1. Clean the aluminum sheets regularly: Use a mild detergent or aluminum cleaner to remove any dirt, grime, or chemical residues that may be present on the surface. This will prevent the buildup of corrosive substances. 2. Apply a protective coating: Consider applying a protective coating on the aluminum sheets. There are various types of coatings available, such as clear coats, anodizing, or painting. These coatings act as a barrier between the aluminum and the surrounding environment, preventing corrosion. 3. Avoid contact with corrosive substances: Aluminum can be susceptible to corrosion when it comes into contact with certain chemicals, such as acids, alkalis, or saltwater. Be mindful of the environment in which the aluminum sheets are stored or used and avoid exposure to these corrosive substances. 4. Use proper storage methods: Store aluminum sheets in a dry environment with low humidity levels. Moisture can accelerate the corrosion process, so it's important to keep the sheets dry and protected from excessive moisture. 5. Implement preventive measures: Consider using corrosion inhibitors or anti-corrosion sprays specifically designed for aluminum. These products can provide an extra layer of protection against corrosion, especially in harsh or corrosive environments. By following these preventive measures, you can significantly reduce the risk of corrosion on aluminum sheets and prolong their lifespan.

- Q: How is an aluminum sheet manufactured?

- An aluminum sheet is manufactured through a process called rolling. The first step involves heating a large aluminum ingot to a specific temperature in a furnace. Once the ingot reaches the desired temperature, it is transferred to a rolling mill. In the rolling mill, the heated aluminum ingot is passed between a series of rolling stands. These stands consist of two steel rollers that exert pressure on the aluminum, gradually reducing its thickness. As the ingot passes through each stand, the distance between the rollers is adjusted to achieve the desired thickness. Throughout the rolling process, the aluminum sheet is continuously cooled with water to prevent it from overheating. This also helps to increase its strength and hardness. The cooling process may vary depending on the specific alloy and properties required for the sheet. After the desired thickness is achieved, the aluminum sheet is further processed to enhance its surface finish. This includes processes like annealing, where the sheet is heated and then slowly cooled to relieve any internal stresses and improve its workability. Finally, the aluminum sheet is cut into desired sizes and shapes using shearing or sawing techniques. It can also undergo additional treatments such as coating, painting, or polishing depending on its intended application. Overall, the manufacturing of an aluminum sheet involves heating the ingot, rolling it between sets of steel rollers to reduce its thickness, cooling it, and then further processing to achieve the desired surface finish and size. This process ensures the production of high-quality aluminum sheets that can be used in various industries such as construction, automotive, aerospace, and more.

- Q: Can aluminum sheets be bent into complex shapes?

- Yes, aluminum sheets can be bent into complex shapes due to their malleability and ductility. With the appropriate tools and techniques, aluminum sheets can be formed into intricate and customized designs, making them versatile for various applications.

- Q: Are aluminum sheets suitable for electrical transformers?

- Yes, aluminum sheets are suitable for electrical transformers. Aluminum has excellent electrical conductivity, lightweight properties, and good thermal conductivity, making it an ideal choice for transformer applications. Additionally, aluminum is cost-effective and readily available, further contributing to its suitability for use in electrical transformers.

- Q: What is the classification of 6061106070 aluminum plate, which respectively represent what it means to ask God for help

- Three, the beginning of the aluminum manganese alloy, 3003, 3004, 3015 and so on, the use of a wide range, also known as rust aluminum. Four, the beginning of the four Department of aluminum is aluminum silicon alloy, on behalf of 4A01 five, the beginning of the aluminum magnesium alloy, there are 5052, 5083 and so on, the use of more than three series, the domestic manufacturers can do.

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

- Q: Can 101 aluminum sheets be polished to a mirror-like finish?

- Yes, 101 aluminum sheets can be polished to a mirror-like finish.

Send your message to us

5052 Aluminum Sheets for Sale - Direct Casting Aluminium Coils for Secondary Rolling

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 50000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords