Checker Plate Aluminum Sheets

Checker Plate Aluminum Sheets Related Searches

Aluminum Checker Plate Sheet Checker Plate Aluminum Aluminum Sheet Plate Tread Plate Aluminum Sheets Aluminum Checkered Plate Diamond Plate Aluminum Sheets Aluminum Tread Plate Sheets Aluminum Sheet And Plate Sheets Of Aluminum Diamond Plate Aluminium Checkered Plate Polished Aluminum Checker Plate Aluminum Tread Plate Sheet Sheet Of Diamond Plate Aluminum Polished Aluminum Sheet Aluminum Sheet Diamond Plate Sheet Diamond Plate Aluminum Diamond Plate Sheet Aluminum Diamond Checker Plate Aluminum Black Aluminum Checker Plate Aluminum Checker Plate For Sale Polishing Checker Plate Aluminum Sheet Aluminum Diamond Plate 1 4 Aluminum Checker Plate Diamond Plate Aluminum Sheeting Aluminum Tread Plate Sheet Metal Aluminum Checker Plate Sizes Aluminum Circle Sheet Aluminum Checker Plate Suppliers Rolled Aluminum Sheet Checker Plate Aluminum PriceChecker Plate Aluminum Sheets Supplier & Manufacturer from China

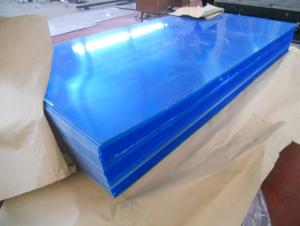

Checker Plate Aluminum Sheets are a type of aluminum sheet material characterized by a raised diamond pattern on one side, providing slip resistance and durability. These sheets are made from high-quality aluminum alloys and are known for their excellent strength-to-weight ratio, corrosion resistance, and ease of fabrication. The diamond pattern also offers a non-slip surface, making it ideal for a variety of applications where safety and functionality are paramount.Checker Plate Aluminum Sheets are widely used across various industries, including construction, automotive, aerospace, and marine. They are commonly found in applications such as flooring, walkways, stair treads, platforms, and ramps, where slip resistance is crucial. The material's lightweight nature and resistance to corrosion make it a popular choice for outdoor and high-wear environments. Additionally, its aesthetic appeal has led to its use in decorative applications and as a component in the manufacturing of various products.

Okorder.com is a leading wholesale supplier of Checker Plate Aluminum Sheets, boasting a large inventory to meet the diverse needs of customers worldwide. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Checker Plate Aluminum Sheets they provide are of the highest standard, making them a reliable choice for businesses and individuals seeking this versatile and durable material.

Hot Products