Skid-Proof Aluminum Alloy Checker Plate for Fence - Best Price Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1.Structure of Skid-Proof Aluminum Alloy Checker Plate Description:

They are widely used in construction and decoration, hardware and electric appliances manufacture, automobile manufacture and other industrial and civil purposes, such as electronic capacitor, rice cooker, refrigerator, computer casting, lamp shade, air-conditioner, cosmetics cover and box, air-conditioner radiator, inner container of disinfecting cabinet, ceiling board, automobile motherboard, cover board and top board, etc.

2.Main Features of Skid-Proof Aluminum Alloy Checker Plate :

Good Corrosion Resistance

Good Machinability

High Quality

Competitive Price

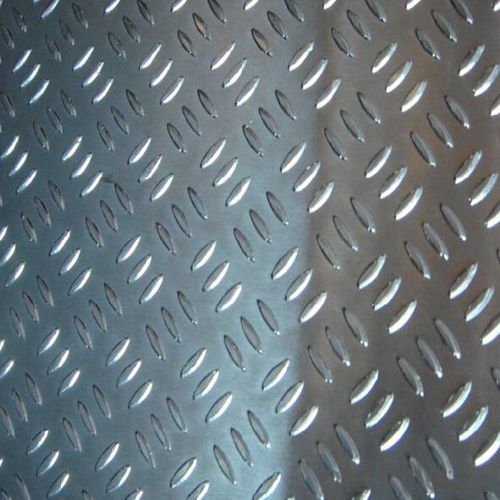

3. Skid-Proof Aluminum Alloy Checker Plate Images:

4. Skid-Proof Aluminum Alloy Checker Plate Specification:

| Alloy | Si | Fe | Cu | Mn | Mg | Cr | Ni | Zn | Ti | Other | Al | ||

| Single | Total | ||||||||||||

| 1060 | 0.25 | 0.35 | 0.05 | 0.03 | 0.03 | _ | _ | 0.05 | V:0.05 | 0.03 | 0.03 | _ | 99.6 |

| 1050 | 0.25 | 0.4 | 0.05 | 0.05 | 0.05 | _ | _ | 0.05 | V:0.05 | 0.03 | 0.03 | _ | 99.5 |

| 1100 | Si+Fe:0.95 | 0.05~0.40 | 0.05 | _ | _ | _ | 0.1 | _ | _ | 0.05 | 0.15 | 99 | |

| 1200 | Si+Fe:1.00 | 0.05 | 0.05 | _ | _ | 0.1 | _ | 0.05 | 0.05 | 0.15 | 99 | ||

| 3003 | 0.6 | 0.7 | 0.05~0.20 | 1.0~1.5 | _ | _ | _ | 0.1 | _ | 0.05 | 0.15 | R | |

| 3004 | 0.3 | 0.7 | 0.25 | 1.0~1.5 | 0.8~1.3 | _ | _ | 0.25 | _ | 0.05 | 0.15 | R | |

| 3005 | 0.6 | 0.7 | 0.3 | 1.0~1.5 | 0.20~0.6 | 0.1 | _ | 0.25 | 0.1 | 0.05 | 0.15 | R | |

| 3105 | 0.6 | 0.7 | 0.3 | 0.30~0.8 | 0.20~0.8 | 0.2 | _ | 0.4 | 0.1 | 0.05 | 0.15 | R | |

| 5005 | 0.3 | 0.7 | 0.2 | 0.2 | 0.50~1.1 | 0.1 | _ | 0.25 | _ | _ | 0.05 | 0.15 | R |

| 5052 | 0.25 | 0.4 | 0.1 | 0.1 | 2.2~2.8 | 0.15~0.35 | _ | 0.1 | _ | _ | 0.05 | 0.15 | R |

| 5083 | 0.4 | 0.4 | 0.1 | 0.40~1.0 | 4.0~4.9 | 0.05~0.25 | _ | 0.25 | _ | 0.15 | 0.05 | 0.15 | R |

| 5086 | 0.4 | 0.5 | 0.1 | 0.20~0.7 | 3.5~4.5 | 0.05~0.25 | _ | 0.25 | _ | 0.15 | 0.05 | 0.15 | R |

5.FAQ

Q1.How long have you been in this product?

A1:More than 10 years.

Q2. What's the minium quantity(MOQ)?

A2. 5 Metric tons

Q3. How long is shipping time?

A3. 7 (ready-made products)-25 days(OEM)

Q4. How do you guarantee the quality?

A4. 1. Cooperating and Exchaning experience with sevral quoted aluminum companies

2. Japanese and Swiss production line and skilled works (regular training and testing)

3. more than 10 years production experience.

Q5. Do you have after sale service?

A5. Yes. Any quality problem occurs within one year, pls take photoes,we will be responsible.

- Q: Can 101 aluminum sheets be embossed or textured?

- It is possible to emboss or texture 101 aluminum sheets. Aluminum is a highly adaptable material that can be easily molded and formed. To emboss or texture aluminum sheets, pressure or heat is applied to create patterns that are either raised or recessed on the surface. There are different methods available for this process, including mechanical embossing or chemical etching. As long as the aluminum sheets are of suitable thickness and good quality, it is feasible to achieve desired designs and patterns through embossing or texturing.

- Q: Can aluminum sheets be used for window frames?

- Indeed, window frames can be made using aluminum sheets. The utilization of aluminum for window frames is widespread because of its durability, lightweight characteristics, and ability to resist corrosion. Aluminum frames provide exceptional strength and stability and can be effortlessly tailored to suit any window size or shape. Moreover, aluminum frames necessitate minimal upkeep and can be painted or anodized to match any preferred color or finish. In summary, aluminum sheets serve as a versatile and dependable material for the construction of window frames.

- Q: how to connect copper pipe and aluminum sheet?

- it depends on the size and requirement, we can use ultrasonic wave rolling welding to connect copper pipe and aluminum sheet.for example, solar energy radiator-fan contains connection of copper pipe and copper sheet, ultrasonic wave rolling welding equipment is used here.ultrasonic wave welding of metals is suitable for the welding of copper to copper, copper to aluminum and aluminum to aluminum.

- Q: If one were to hit someone with a baseball bat, would it cause more pain to use a wooden bat or an aluminum one? Just wondering.

- While I fortunately have not been hit with either, I would think the wooden bat, with its increased weight, could be swung more forcefully and would hurt more.

- Q: How do you prevent galvanic corrosion when using aluminum sheets with concrete?

- To prevent galvanic corrosion when utilizing aluminum sheets in conjunction with concrete, there are several precautionary measures that can be employed: 1. Barrier Coating: Apply a protective barrier coating or paint onto the aluminum sheets to create a separation between them and the concrete. This coating functions as a safeguarding layer, hindering direct contact between the aluminum and the concrete, thereby diminishing the likelihood of galvanic corrosion. 2. Insulation: Introduce an insulating material between the aluminum sheets and the concrete. This material can take the form of a non-conductive plastic or rubber sheet that effectively isolates the aluminum from the concrete, minimizing the potential risk of galvanic corrosion. 3. Surface Treatment: Administer a corrosion-resistant treatment to the aluminum sheets. Anodizing is a prevalent surface treatment technique that generates a protective oxide layer on the aluminum surface, augmenting its resistance to corrosion when in contact with concrete. 4. Utilize Dissimilar Metals: Refrain from employing dissimilar metals in conjunction with aluminum sheets and concrete. When dissimilar metals, such as steel or iron, come into contact with aluminum in the presence of moisture, the likelihood of galvanic corrosion increases. Hence, it is advisable to employ aluminum fasteners or supports when working with aluminum sheets and concrete. 5. Adequate Drainage: Ensure proper drainage in areas where aluminum sheets are in contact with concrete. Accumulation of water or moisture can expedite galvanic corrosion. By ensuring sufficient drainage, the amount of moisture that comes into contact with the aluminum can be minimized, thereby reducing the risk of corrosion. 6. Routine Maintenance: Regularly inspect and maintain the aluminum sheets and their protective measures. If any damage or deterioration is detected, promptly repair or replace the barrier coatings, insulation, or surface treatments to ensure continuous protection against galvanic corrosion. By implementing these preventative measures, the risk of galvanic corrosion when employing aluminum sheets with concrete can be significantly mitigated, thereby prolonging the longevity and integrity of both the aluminum and the concrete structures.

- Q: Can aluminum sheet be used for signage?

- Certainly! Aluminum sheet is a viable option for signage purposes. Its durability, versatility, and cost-effectiveness make it a popular choice among sign makers. Being a lightweight material, it is resistant to corrosion, making it suitable for both indoor and outdoor signage. With aluminum sheet, one can easily cut, shape, and form it into various sizes and designs, allowing for customizable signage options. Moreover, it is effortless to print or engrave upon, making it perfect for displaying text, graphics, and logos. Its sleek and professional appearance enhances its appeal for signage purposes. In conclusion, aluminum sheet is an excellent choice for signage due to its durability, versatility, and aesthetic qualities.

- Q: Can aluminum sheet be used for reflective surfaces?

- Yes, aluminum sheet can be used for reflective surfaces. Aluminum is known for its high reflectivity, making it a popular choice for various applications that require reflective surfaces. Aluminum sheets can be polished to a high shine, allowing them to reflect light and create a mirrored effect. This makes them ideal for uses such as reflectors in lighting fixtures, solar panels, mirrors, and decorative purposes. Additionally, aluminum's reflective properties make it suitable for applications where heat reflection is required, such as in thermal insulation or roofing materials. Overall, aluminum sheets are a versatile and effective option for creating reflective surfaces.

- Q: I've heard twice in the past 2 days on ESPN that they think Aluminum bats are dangerous. I disagree with this cause if they were dangerous why would they allow them to use them in college and high school. Isnt that what the BESR certification mean that the bat is safe that the ball isnt going to come off at super high speeds. i just wanted to get your opinion.

- Yes I heard this also and let me tell you something the wooden bats are also dangerous. I hate hitting a ball and then I get stung and that hurts. I like the aluminum bats better, so they should just keep them on the market because they are not so much dangerous then the wooden one's.

- Q: I've heard certain eyeliners contain lead and that it's a harmful (cancerous) ingredient. I use Urban Decay's 24/7 eyeliner and on the box it says it contains aluminum powder. Is that another word for lead? If not, is aluminum powder harmful too? Thanks!

- Aluminium and lead are two different elements - they're not the same thing. (Aluminium is the stuff that soft drink cans are made of.) But i would watch out for aluminium as well. There is a small amount of evidence that aluminium might be linked to Alzheimers and things like that. It's much *less* of a risk than lead, but generally metal powders are not things that you want in your body, if you can avoid it.

- Q: What are the safety precautions when working with aluminum sheet?

- To ensure your well-being and reduce the likelihood of accidents or injuries, it is essential to observe specific safety measures when working with aluminum sheet. Consider the following precautions: 1. Personal Protective Equipment (PPE): Safeguard yourself against potential hazards by wearing appropriate PPE, such as safety glasses, gloves, and a long-sleeved shirt. Aluminum shavings can cause injuries if they come into contact with your skin due to their sharpness. 2. Ventilation: Work in a well-ventilated area or employ local exhaust ventilation systems to prevent the accumulation of fumes and dust. Inhalation of large quantities of aluminum dust or fumes can be harmful. 3. Fire safety: As aluminum is highly flammable, it is crucial to keep flammable materials away from the work area. Ensure you have a fire extinguisher readily available and know how to use it in case of emergencies. 4. Tool safety: Verify that all tools and equipment used for cutting, bending, or shaping aluminum are in good working condition. Accidents are more likely to occur with dull or damaged tools. Follow proper tool handling techniques and avoid using excessive force to minimize the risk of injuries. 5. Proper handling: When moving or lifting aluminum sheets, employ correct lifting techniques and seek assistance if needed. Improper handling can lead to strains or muscle injuries due to the weight of the sheets. 6. Electrical safety: If electrical tools or equipment are utilized, make sure they are properly grounded and in good working order. Avoid using damaged or frayed cords and keep them away from moisture sources. 7. Storage: Store aluminum sheets in a designated area, away from heat sources or flammable materials. Stack and secure the sheets properly to prevent accidents caused by falling objects. 8. First Aid: Keep a first aid kit readily available to address minor injuries. Familiarize yourself with appropriate first aid procedures for cuts, burns, or any other potential injuries that may occur while working with aluminum sheets. By adhering to these safety precautions, you can establish a safe working environment and minimize the risks associated with handling aluminum sheets. Remember to prioritize your safety and the safety of those around you at all times.

Send your message to us

Skid-Proof Aluminum Alloy Checker Plate for Fence - Best Price Aluminum Sheets

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords