Tread Plate Aluminum Sheets

Tread Plate Aluminum Sheets Related Searches

Aluminum Tread Plate Sheets Aluminum Tread Plate Sheet Aluminum Tread Plate Sheet Metal Tread Plate Aluminum Aluminum Sheet Plate Checker Plate Aluminum Sheets Tread Aluminum Plate Diamond Plate Aluminum Sheets Aluminum Tread Plate Sheet 4x8 Aluminum Checker Plate Sheet Aluminum Sheet And Plate Aluminum Tread Plate For Sale Aluminum Tread Plate Patterns Diamond Plate Sheet Aluminum Polished Aluminum Tread Plate Sheets Of Aluminum Diamond Plate Aluminum Sheet Diamond Plate Diamond Tread Plate Aluminum Black Aluminum Tread Plate Sheet Of Diamond Plate Aluminum Aluminum Tread Plate Home Depot Sheet Diamond Plate Aluminum Aluminum Diamond Tread Plate Aluminum Tread Plate Tool Box Polished Aluminum Sheet Bright Aluminum Tread Plate Aluminum Tread Plate Suppliers Sheet Aluminum Diamond Plate Embossed Aluminum Tread Plate Aluminum Tread Plate PricesTread Plate Aluminum Sheets Supplier & Manufacturer from China

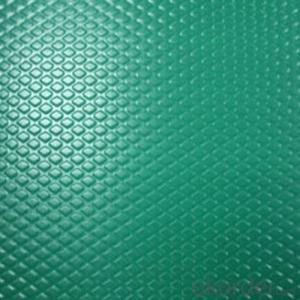

Tread Plate Aluminum Sheets are a type of aluminum sheet material that features a distinctive patterned surface, designed to provide enhanced grip and durability. These sheets are constructed with a raised diamond pattern, which offers superior traction and resistance to slipping, making them ideal for various applications where safety and stability are paramount.Tread Plate Aluminum Sheets are widely used in a range of industries and settings, including construction, transportation, and manufacturing. They are commonly found in applications such as stair treads, walkways, flooring, and ramps, where slip resistance is crucial. Additionally, these sheets can be utilized in the production of truck beds, dock plates, and other equipment that requires a non-slip surface. The versatility of Tread Plate Aluminum Sheets makes them a popular choice for both commercial and industrial purposes.

Okorder.com is a leading wholesale supplier of Tread Plate Aluminum Sheets, boasting a vast inventory that caters to the diverse needs of customers across different sectors. With a commitment to quality and customer satisfaction, Okorder.com ensures that the Tread Plate Aluminum Sheets they provide meet the highest industry standards.

Hot Products