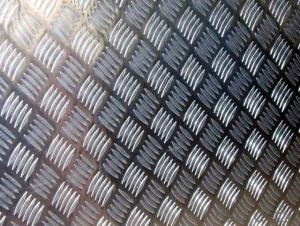

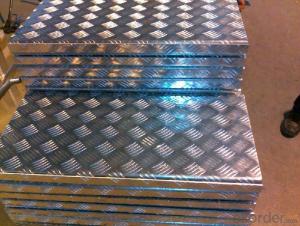

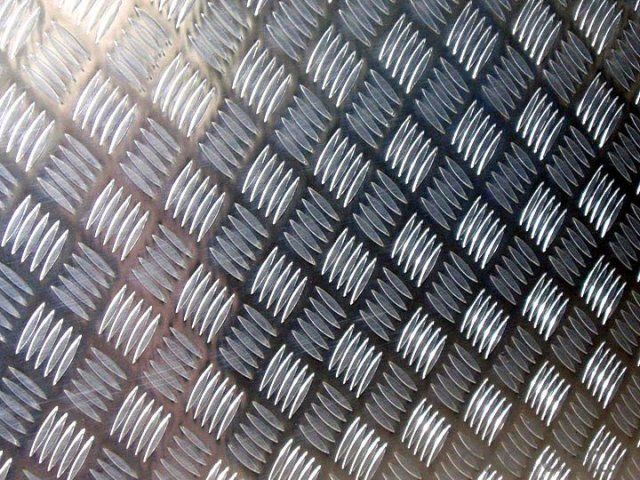

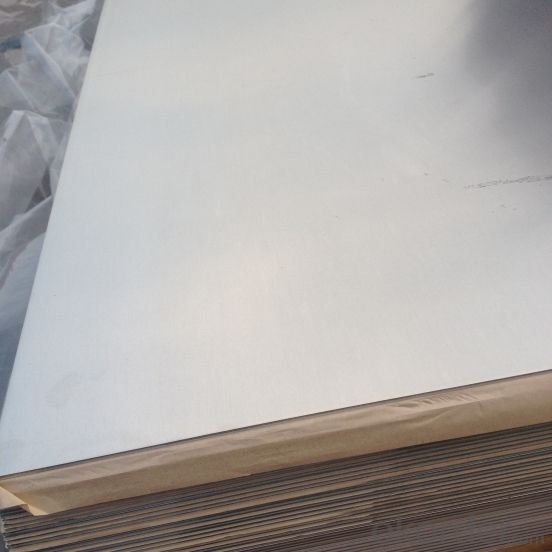

Aluminum Roof Sheets India - Two Bar Diamond Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

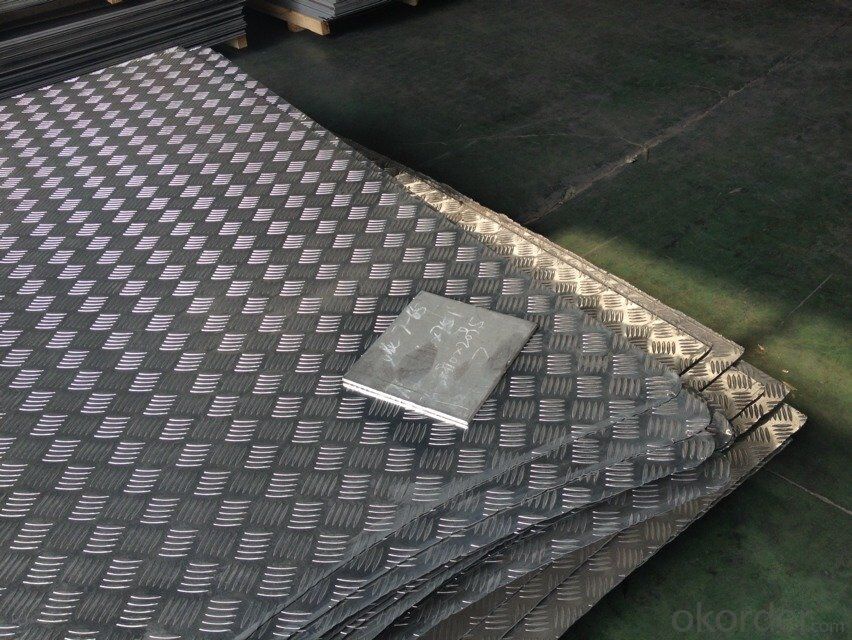

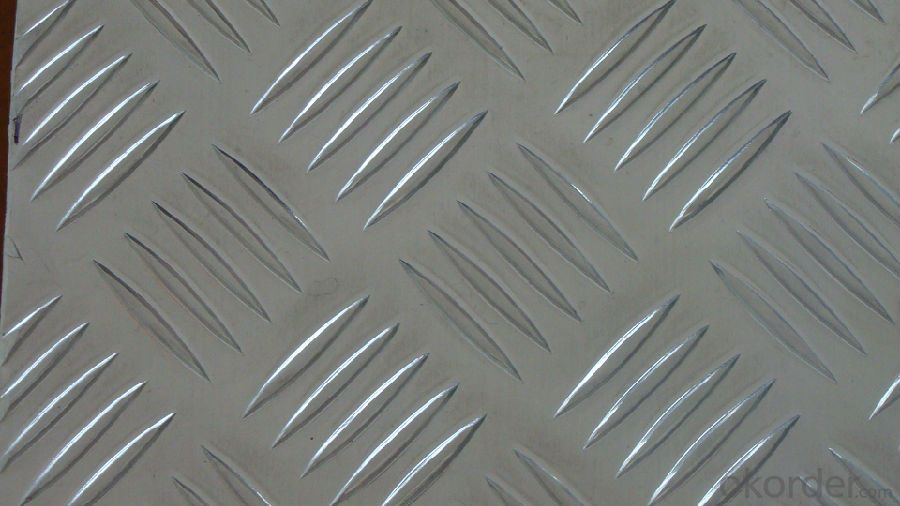

aluminum chequered plate are widely usd for bus, cars and shipping vessel as the floor....

Aluminum tread plate is also called anti-slide aluminum sheet which is widely used in manufacturing vehicles, ships, washing machines, refrigerator shell, etc.

Specification:

Alloy: 1050, 1060, 1100, 3003, 3105, 5052

Temper: O, H12, H14, H16, H18, H22, H24, H26, H32

Thickness: 1.0~10mm

Width: 1000~1600mm

Length: 1000~6000mm

Packing:

One roll in an individual box or printed PP bag

Certain quantities in a standard carton

Depends on customer’s request

Service

1. We have the good and professional team, have a good after-sales service.

2. Accept any drawings or your samples to develop new product.

3. Offer relateive technical support,quick response,all your inquire will replied within 24 hours.

4. OEM, buyer design, buyer label services provided.

5. Have the certification of ISO 9001, SGS.

6. Special discount and protection of sales area provided to our distributor.

FAQ

Q1:Do you provide sample? How many days will samples be finished?

Free samples will be provided if needed, but customers should undertake shipping cost or freight charges, samples will be finished in 5-7days

Q2: Can we visit your factory?

Welcome to our factory at any time.

Q3: Complaint solving process

Finding your salesman—Salesman provide you the solution (If it’s our responsibility, we will resend substitutes or return money or provide discount for your next order, etc.; If it’s shipping company’s responsibility, we will also help you until the problem is resolved.) —If salesman can’t solve your problem, please call our manager .

Q4: Delivery time

3~30working days after confirming the payment. If the order is urgent, we will push our workers to finish in advance.

Q5: What's your MOQ?

Normally 8MT are requested as the minium order quantity ,we shall give

additional instructions in special circumstances.

Q6: What are the terms of payment and currencies do you accept?

T/T or L/C is accepted, currently we appreciated your payment through

USD,EUR, RMB

Q7: Do you accept customized orders?

Yes, we do. Your customized orders are always welcomed. Please kindly offer us your samples or drawings, so that we can customize the products according to your preferences. About any further detail, please feel free to contact us.

Q8: What information should I let you know if I want to get a quotation?

Your detailed requirements regarding the products's dimensions, including shape, thickness, top out (length*width*height), and your order quantity are highly appreciated if you want further information about our quotation

Q9: How about the mass production?

The lead time of mass production depend on quantity, usually 25-30days (20FT) .

- Q: Is it possible to utilize aluminum sheets in the construction of high-rise buildings?

- <p>Yes, aluminum sheets can be used in high-rise buildings. They are valued for their lightweight, high strength, and resistance to corrosion. Aluminum is often used in curtain walls, window frames, and roofing due to its durability and recyclability. It also offers design flexibility and can be easily shaped and joined, making it suitable for modern architectural designs. However, it's important to ensure that the aluminum used meets the specific building codes and safety standards for high-rise construction.</p>

- Q: Are aluminum sheets suitable for marine vessel construction?

- Yes, aluminum sheets are suitable for marine vessel construction. Aluminum is a lightweight yet strong material that offers excellent corrosion resistance in marine environments. It is commonly used in the construction of various marine vessels, including boats, ships, and yachts. One of the main advantages of using aluminum sheets in marine vessel construction is their high strength-to-weight ratio. This allows for the construction of lighter vessels, which can result in improved fuel efficiency, increased speed, and better handling. Additionally, the lightweight nature of aluminum makes it easier to transport and maneuver during the construction process. Another key benefit of aluminum sheets for marine vessel construction is their exceptional resistance to corrosion. Aluminum naturally forms a protective oxide layer on its surface, which prevents further oxidation and corrosion. This makes aluminum an ideal choice for marine environments, where vessels are constantly exposed to saltwater, humidity, and other corrosive elements. Furthermore, aluminum sheets can be easily fabricated and welded, providing flexibility in the design and construction of marine vessels. They can be shaped into various forms, allowing for the creation of complex hull structures and interior components. Aluminum also offers good thermal conductivity, which can help regulate temperature in the interior spaces of marine vessels. While aluminum sheets have many advantages for marine vessel construction, it is important to consider certain factors. Aluminum is susceptible to galvanic corrosion when it comes into contact with certain metals, such as steel or bronze. Therefore, proper insulation and anti-corrosion measures should be taken to prevent galvanic corrosion in aluminum-based vessels. In conclusion, aluminum sheets are highly suitable for marine vessel construction. Their lightweight, high strength-to-weight ratio, corrosion resistance, and ease of fabrication make them an ideal choice for building durable and efficient marine vessels. However, proper precautions should be taken to prevent galvanic corrosion when aluminum is used alongside other metals.

- Q: Is it possible to use aluminum sheets as a material for exterior wall cladding?

- <p>Yes, aluminum sheets are commonly used for exterior wall cladding due to their durability, low maintenance, and resistance to weather conditions. They are lightweight, easy to install, and can be recycled, making them an environmentally friendly option. Aluminum sheets can also be painted or coated in various colors and finishes, offering design flexibility. However, it's important to ensure proper installation and sealing to prevent water infiltration and to maintain the integrity of the cladding system.</p>

- Q: where can I sell aluminum tabs from aluminum cans in Palmdale, Califronia?

- For okorder /

- Q: What are the different thicknesses available for aluminum sheet?

- Aluminum sheets come in various thicknesses, spanning from very thin to thick. The thickness of these sheets is measured either in gauge or millimeters (mm), with each gauge denoting a specific thickness. The prevalent gauges for aluminum sheets are 22, 24, 26, 28, 30, and 32, corresponding to thicknesses ranging from 0.0254 mm to 0.635 mm. Moreover, thicker gauges, such as 16 gauge (1.29 mm) or even more substantial ones, can be found for specialized applications. The preferred thickness of an aluminum sheet is determined by its intended use. Thinner sheets are often utilized for lightweight purposes, including electronics or packaging, while thicker sheets are more suitable for structural or industrial needs.

- Q: Is it possible to utilize aluminum sheets in interior design projects?

- <p>Yes, aluminum sheets can be used for interior design purposes. They are lightweight, durable, and resistant to corrosion, making them suitable for various applications such as wall cladding, ceilings, and furniture. Aluminum sheets can also be painted or anodized to achieve different finishes, adding aesthetic appeal to your design. However, it's important to consider the specific requirements of your project, such as load-bearing capacity and thermal insulation, as these properties can vary with different types of aluminum sheets.</p>

- Q: And isn't aluminum extremely bad for ones health?

- Well, I'm looking at my deodorant now, it looks like aluminum zirconium tetrachlorohydrex is the active ingredient, the actual anti perspirant part. This is probably why it is a bad idea to eat it.

- Q: How many atoms are in a 2.80 cm* 2.80cm*2.80cm cube of aluminum?

- 2.8cm * 2.8cm * 2.8cm= 21.95 cm^3 is volume of Aluminum present Density of Al = 2.7g/cm^3 Convert volume of aluminum into grams of Aluminum, make sure your units cancel 21.95 cm^3 * (2.7g/1 cm^3) = 59.26 g Al Next, find how many moles of Al you have. MW Al = 27g/mol 59.26/27 = 2.19 moles Al Use Avogadro's number to find number of atoms of Al - 2.19 moles Al * (6.022x10^23 atoms/1 mol Al) = 1.32x10^24 atoms Al

- Q: Can aluminum sheets be used for packaging?

- Yes, aluminum sheets can be used for packaging due to their lightweight, corrosion-resistant, and recyclable properties.

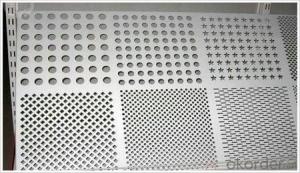

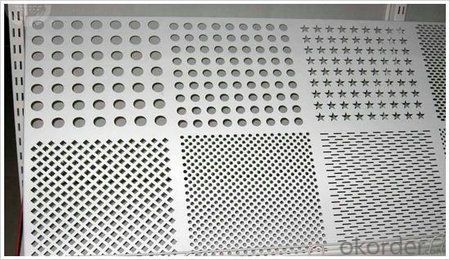

- Q: This question asks about the various surface treatments or finishes that can be applied to custom-made aluminum sheets.

- <p>Custom-made aluminum sheets can be finished in a variety of ways to achieve different aesthetic and functional properties. Some of the common finishes include: Anodizing, which provides a protective oxide layer and can be colored; Powder coating, offering a durable and colorful finish; Mill finish, which is the natural surface of the aluminum after rolling; Brushed or Satin finish, giving a鍝戝厜 texture; Mirror finish, providing a reflective, polished surface; and Painted finish, where the aluminum is coated with a layer of paint for color and protection. Each finish serves different purposes, from enhancing corrosion resistance to improving the visual appeal of the aluminum sheet.</p>

Send your message to us

Aluminum Roof Sheets India - Two Bar Diamond Aluminum Tread Plate

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 8 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords