Grades Of Aluminum Plate

Grades Of Aluminum Plate Related Searches

Marine Grade Aluminum Plate Types Of Aluminum Plate Aluminum Plate Sizes Thickness Of Aluminum Plate Aluminum Plate Thicknesses Aluminum Plate Tolerances Aluminum Plate Thickness Chart Density Of Aluminum Plate Aluminum Plate Prices Standard Aluminum Plate Sizes Aluminum Floor Plate Aluminum Plate Panels Aluminum Plate Texture Aluminum Wall Plate Aluminum Plate Weight Chart Weight Of Aluminum Plate Aluminum Surface Plate Aluminum Profile Plate Aluminum Grid Plate Aluminum Metal Plate Ground Aluminum Plate Aluminum Threshold Plate Aluminum Plate Price Buy Aluminum Plate Aluminum Base Plate Aluminum License Plate Gold Plate Aluminum Forming Aluminum Plate Aluminum Cooking Plate Aluminum Flat PlateGrades Of Aluminum Plate Supplier & Manufacturer from China

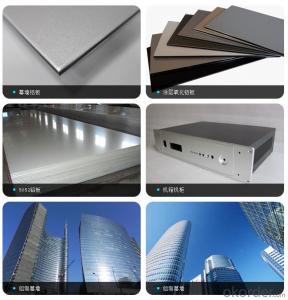

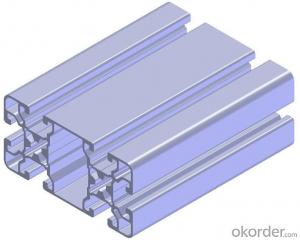

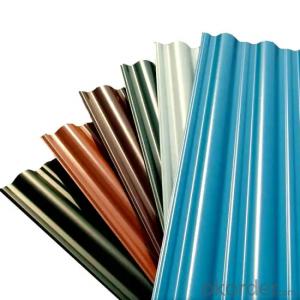

Grades of aluminum plate are a versatile and widely used material in various industries, offering a range of mechanical properties and corrosion resistance. These plates come in different grades, each with its own unique characteristics, making them suitable for diverse applications. The aluminum plates are known for their lightweight, strength, and durability, which makes them ideal for construction, automotive, aerospace, and many other sectors.Aluminum plates are utilized in numerous applications, such as in the manufacturing of vehicle parts, building facades, and electronic components. Their ability to be easily shaped and formed, coupled with their resistance to corrosion, makes them a popular choice for both functional and aesthetic purposes. The versatility of these plates allows them to be used in a broad spectrum of industries, providing solutions for a multitude of challenges and requirements.

Okorder.com is a leading wholesale supplier of grades of aluminum plate, boasting a vast inventory that caters to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that their aluminum plates meet the highest standards and are available at competitive prices. This makes them an ideal choice for businesses looking to source high-quality aluminum plates for their projects and applications.

Hot Products