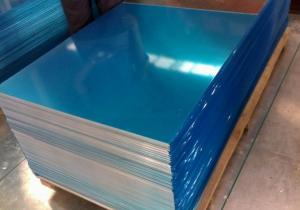

Aluminum Veneer Sheets - Aluminium Circle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

You Might Also Like

ALLOY:AA1***(AA1050,AA1070,AA1100etc)

AA3***(AA3003 etc)

TEMPER:O,H14

THICKNESS:0.5mm-4mm

DIAGONAL:100mm-1200mm

STANDARD:GB/T 3880-2006

Special specification is available on customer's requirement

- Q: How do aluminum sheets perform in terms of thermal expansion?

- Aluminum sheets exhibit a relatively high coefficient of thermal expansion, causing them to expand significantly under heat and contract when cooled. This behavior stems from aluminum's nature as a metal with a relatively low melting point and excellent heat conductivity. Heating aluminum sheets increases the energy of its metal atoms, causing them to vibrate and move more rapidly, resulting in expansion. Conversely, cooling the sheets reduces their energy, causing the metal atoms to slow down and move closer together, leading to contraction. Therefore, it is crucial to consider the thermal expansion properties of aluminum sheets when using them in applications that involve temperature fluctuations, as this can impact the material's overall dimensions and performance.

- Q: Can aluminum sheets be used for protective enclosures?

- Yes, aluminum sheets can be used for protective enclosures. Aluminum is a versatile and lightweight material that offers excellent durability and corrosion resistance. It can be easily fabricated into various shapes and sizes, making it suitable for constructing protective enclosures for a wide range of applications. Aluminum enclosures are commonly used in industries such as electronics, telecommunications, aerospace, and automotive. They provide protection against environmental elements, such as moisture, dust, and electromagnetic interference. Additionally, aluminum enclosures can be further enhanced with coatings or insulation materials to meet specific requirements for thermal insulation, fire resistance, or electrical conductivity. Overall, aluminum sheets are a reliable choice for protective enclosures due to their strength, versatility, and ability to withstand harsh conditions.

- Q: How is aluminum sheet made?

- Aluminum sheet is made through a process called rolling, which involves passing a preheated aluminum ingot through a series of rolling mills. The initial step is the heating of the ingot to a specific temperature to make it more malleable. Once heated, the ingot is then passed through a series of rolling mills, where it is continuously pressed and stretched to reduce its thickness and increase its length. The rolling mills consist of a pair of rotating cylinders with grooves on their surfaces. As the ingot passes through these cylinders, it is compressed and elongated, resulting in a thinner and longer sheet. The process is repeated multiple times, with each pass reducing the thickness of the sheet further. To maintain the desired thickness and dimensions, the sheet is periodically annealed, which involves heating it to a specific temperature and then slowly cooling it. This annealing process helps relieve internal stresses and ensures the sheet retains its desired properties. Once the desired thickness is achieved, the aluminum sheet is cooled, trimmed, and cut into specific lengths or rolled into coils for further processing or distribution. The final product is a flat, thin, and versatile sheet of aluminum that can be used in a wide range of applications, from construction and automotive industries to packaging and electrical appliances.

- Q: Do 101 aluminum sheets have any specific sound or vibration damping properties?

- Yes, 101 aluminum sheets have specific sound and vibration damping properties. Aluminum is known for its high damping capacity, which means it can effectively reduce vibrations and dampen noise. The specific properties of 101 aluminum sheets make them excellent choices for applications where sound and vibration control are desired, such as in the automotive and aerospace industries.

- Q: Can aluminum sheets be brushed or satin finished?

- Aluminum sheets have the capability to undergo brushing or satin finishing. Brushing or satin finishing is a method that involves the creation of a textured surface on the aluminum sheets. This can be accomplished by utilizing abrasive materials like sandpaper or wire brushes to generate a pattern of fine lines or scratches on the metal's surface. The purpose of this process is often to enhance the appearance of the aluminum sheets by providing them with a more matte and textured finish. Moreover, brushing or satin finishing can also serve to conceal minor imperfections or scratches on the surface of the aluminum sheets. In summary, the option to brush or satin finish aluminum sheets allows for flexibility in achieving desired aesthetics and surface textures in various applications.

- Q: Cooks are warned not to use aluminum cookware when preparing acidic foods. Why?

- tastes like metal use wood if in doubt

- Q: I have tried every possible one and every time i put it on it makes the smell 10x worse. It doesn't help at all it only makes it worse. Has ANYONE found one that actualy works? I hear that aluminum causes problems like alzheimer's.

- Not only does the aluminum in deordorant cause alzheimers, aluminum is also a known carcinogen, and may be a cause to breast cancer ( a lot of breast cancers are first found in the armpit, or close to it.......where deodorant goes.....crazy) i found one at a health food store.... it's called JASON....and it's apricot scented....it works pretty good, just gotta put it on a lot hope that helps!!

- Q: Can aluminum sheets be used in construction?

- Construction can indeed utilize aluminum sheets. Aluminum, a versatile and lightweight material, possesses numerous advantageous properties for construction purposes. Its corrosion resistance allows for both indoor and outdoor applications. Moreover, aluminum sheets exhibit a high strength-to-weight ratio, granting them durability and strength while remaining relatively lightweight. This characteristic proves advantageous in construction projects where weight is a consideration. Furthermore, aluminum is non-toxic and highly recyclable, making it an environmentally conscious option. When combined with its aesthetic appeal and ease of fabrication, aluminum sheets become a favored choice for a variety of construction applications such as roofing, cladding, wall panels, window frames, and more.

- Q: What types of aluminum sheets are recommended for outdoor applications due to their durability and resistance to weather conditions?

- <p>Yes, there are specific types of aluminum sheets designed for outdoor use. Marine-grade aluminum sheets, such as 5083 or 5086 alloys, are highly resistant to corrosion and are ideal for marine applications. Aluminum sheets with a protective coating, like anodized aluminum or those with a fluoropolymer finish, offer excellent weather resistance and durability. Additionally, aluminum sheets with a mill finish or those coated with a clear coating can also be suitable for outdoor use due to their resistance to UV rays and ability to withstand temperature fluctuations.</p>

- Q: Can aluminum sheets be used for protective barriers?

- Aluminum sheets are indeed suitable for protective barriers. Being both lightweight and durable, aluminum possesses exceptional strength and corrosion resistance. Its utilization is widespread across a multitude of contexts necessitating protection, such as construction sites, industrial facilities, and military installations. By effortlessly undergoing fabrication and shaping, aluminum sheets can be transformed into robust barriers that effectively impede unauthorized access and offer protection against potential hazards. Furthermore, aluminum demonstrates remarkable versatility as it can be combined with materials like glass or steel to heighten its protective capabilities. All in all, due to their strength, durability, and versatility, aluminum sheets represent a dependable choice for protective barriers.

Send your message to us

Aluminum Veneer Sheets - Aluminium Circle

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

Quality Product, Order Online Tracking, Timely Delivery

OKorder Financial Service

Credit Rating, Credit Services, Credit Purchasing

Similar products

Hot products

Hot Searches

Related keywords