All Categories

- - Steel Wire Rod

- - Steel Coils

- - Steel Profiles

- - Steel Pipes

- - Stainless Steel

- - Tinplate

- - Special Steel

- - Steel Sheets

- - Steel Rebars

- - Steel Strips

- - Hot Rolled Steel

- - Cold Rolled Steel

- - Pre-painted Steel

- - Seamless Steel Pipe

- - Welded Steel Pipe

- - Hollow Steel Tubes

- - Galvanized Pipe

- - Stainless Steel Coil

- - Stainless Steel Sheet

- - Stainless Steel Plate

- - Stainless Steel Strips

- - Electrolytic Tinplate Coil

- - Electrolytic Tinplate Sheet

- - Stainless Steel Rebars

- - Solar Panels

- - Solar Water Heater

- - Solar Related Products

- - Solar Inverter

- - Solar Cells

- - Solar Light

- - Solar Energy Systems

- - Solar Controllers

- - Solar Mounting System

- - Solar Pump

- - Solar Chargers

- - Fiberglass Chopped Strand

- - Fiberglass Mesh Cloth

- - Composite Pipes

- - FRP Pultrusion Profiles

- - Fiberglass Mat Tissue

- - Fiberglass Fabrics

- - Fiberglass Mesh

- - Composite Tank

- - Fiberglass Mesh tape

- - Polymer

- - FRP Roofing Panel

- - Fiberglass Roving

- - Monolithic Refractories

- - Ceramic Fiber Products

- - Refractory Bricks

- - Raw Materials For Refractory

- - Suspended Platform

- - Cranes

- - Concrete Machinery

- - Earthmoving Machinery

- - Building Hoist

- - Road Building Machinery

- - Plastic Pipe Fittings

- - Plastic Tubes

- - Plastic Sheets

- - Agricultural Plastic Products

- - Plastic Nets

All Categories

All Categories

Q & A

How are recycled aluminum sheets processed and reintegrated into the production cycle to minimize environmental impact?

Recycled aluminum sheets are processed by first sorting and cleaning them to remove any impurities. The sheets are then shredded into small pieces and melted down in a furnace. The molten aluminum is then cast into ingots or rolled into new sheets. These recycled aluminum sheets are reintegrated into the production cycle by being used as raw material in the manufacturing of various aluminum products. This reduces the need for extracting and refining new aluminum, which is an energy-intensive process with significant environmental impact. By utilizing recycled aluminum, we can minimize the consumption of resources, reduce greenhouse gas emissions, and promote a more sustainable and eco-friendly production cycle.

How do you choose the appropriate surface treatment for aluminum sheets in marine environments?

When choosing the appropriate surface treatment for aluminum sheets in marine environments, several factors need to be considered. These include the level of corrosion resistance required, the specific marine environment (saltwater, freshwater, etc.), the expected lifespan of the aluminum sheets, and the budget constraints. Common surface treatments for aluminum sheets in marine environments include anodizing, chromate conversion coating, and powder coating. Anodizing provides excellent corrosion resistance and durability, making it a popular choice. Chromate conversion coating offers good protection but is less durable. Powder coating provides a decorative and protective finish but may not be as resistant to saltwater corrosion as anodizing. Ultimately, the appropriate surface treatment should be chosen based on careful evaluation of these factors to ensure long-lasting protection for aluminum sheets in marine environments.

How do you cut aluminum sheets?

To cut aluminum sheets, you can use a variety of tools such as a hacksaw, circular saw with a carbide-tipped blade, electric shears, or a plasma cutter. It's important to choose the right tool based on the thickness of the aluminum sheet and the desired accuracy of the cut. Safety precautions like wearing protective goggles and gloves should always be followed.

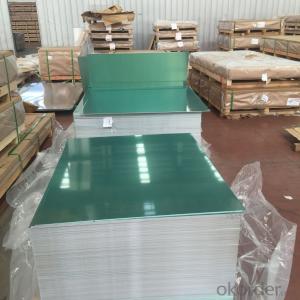

Wholesale Aluminum Sheets from supplier in Montenegro

Our team of experts can guide you in selecting the right aluminum sheets for your specific requirements, whether it be for construction, transportation, or any other industry. We offer a wide variety of aluminum sheet sizes, thicknesses, and finishes to meet your exact specifications.

In addition to supplying high-quality aluminum sheets, we also provide sales and quotes services to ensure a seamless procurement process. Our dedicated sales team is committed to understanding your needs and providing you with competitive pricing options.

Furthermore, we offer technical support services to assist you throughout your project. Our knowledgeable technicians can provide guidance on installation, maintenance, and any other technical queries you may have. With our support, you can ensure the successful completion of your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and a strong global network. This enables us to efficiently source and deliver aluminum sheets to Montenegro, ensuring timely and reliable supply.

We take pride in our extensive experience in the Montenegrin market. Our deep understanding of local regulations, market trends, and customer preferences allows us to offer valuable insights and expertise. By partnering with us, you can benefit from our knowledge and make informed decisions to enhance the success of your projects.

Whether you need aluminum sheets for residential, commercial, or industrial applications, we are your trusted partner in Montenegro. Contact us today to discuss your requirements and experience our exceptional products and services.

In addition to supplying high-quality aluminum sheets, we also provide sales and quotes services to ensure a seamless procurement process. Our dedicated sales team is committed to understanding your needs and providing you with competitive pricing options.

Furthermore, we offer technical support services to assist you throughout your project. Our knowledgeable technicians can provide guidance on installation, maintenance, and any other technical queries you may have. With our support, you can ensure the successful completion of your projects.

As a subsidiary of CNBM, a Fortune Global 500 company, we have access to extensive resources and a strong global network. This enables us to efficiently source and deliver aluminum sheets to Montenegro, ensuring timely and reliable supply.

We take pride in our extensive experience in the Montenegrin market. Our deep understanding of local regulations, market trends, and customer preferences allows us to offer valuable insights and expertise. By partnering with us, you can benefit from our knowledge and make informed decisions to enhance the success of your projects.

Whether you need aluminum sheets for residential, commercial, or industrial applications, we are your trusted partner in Montenegro. Contact us today to discuss your requirements and experience our exceptional products and services.