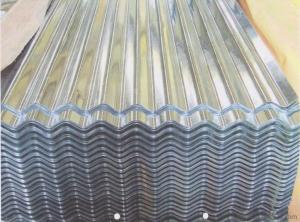

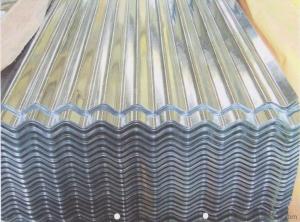

Corrugated Aluminum Sheet

Corrugated Aluminum Sheet Related Searches

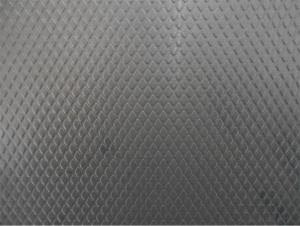

Coil Coated Aluminum Sheet Rolled Aluminum Sheet Polished Aluminum Sheet Corrugated Perspex Sheet Corrugated Aluminum Plate Corrugated Shed Roof Sheets Aluminum Circle Sheet Corrugated Aluminum Foil Aluminum Foil Sheet Aluminum Sheet Plate Clear Anodized Aluminum Sheet Colored Aluminum Foil Sheets Bituminous Corrugated Roofing Sheet Aluminum Sheet Circle Aluminum Checker Plate Sheet Sheet Of Aluminum Foil Black Anodised Aluminium Sheet Aluminum Sheet And Plate Aluminum Sheet Coil Aluminum Sheet With Holes Cutting Aluminum Sheet Perspex Corrugated Roofing Sheet Checker Plate Aluminum Sheets Corrugated Felt Roof Sheets Thick Aluminum Foil Sheets Aluminum Foil Wrap Sheets Diamond Embossed Aluminum Sheet Aluminum Tread Plate Sheet 18 Gauge Aluminum Sheet Large Aluminum Foil SheetsCorrugated Aluminum Sheet Supplier & Manufacturer from China

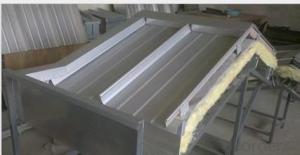

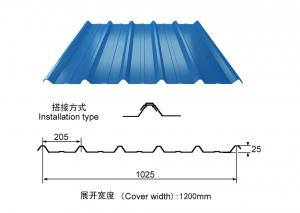

Corrugated Aluminum Sheet is a versatile and durable material that is widely used in various industries due to its unique properties. This product is known for its strength, lightweight, and resistance to corrosion, making it an ideal choice for a multitude of applications. From construction and roofing to agricultural and industrial uses, the corrugated aluminum sheet offers a reliable and long-lasting solution for many different needs.The corrugated aluminum sheet is commonly used in various applications such as roofing, siding, and wall cladding due to its ability to withstand harsh weather conditions and provide a sturdy structure. It is also utilized in the manufacturing of containers, truck bodies, and other transportation equipment, as well as in the creation of signage and display materials. The product's flexibility and adaptability make it a popular choice for a wide range of usage scenarios, allowing for customization and easy installation.

Okorder.com is a leading wholesale supplier of corrugated aluminum sheet, boasting a vast inventory that caters to the diverse needs of clients across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the corrugated aluminum sheet products they offer meet the highest standards and are available at competitive prices. By partnering with Okorder.com, customers can benefit from a reliable source of supply and enjoy the convenience of a one-stop shopping experience for all their corrugated aluminum sheet requirements.