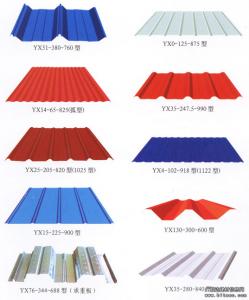

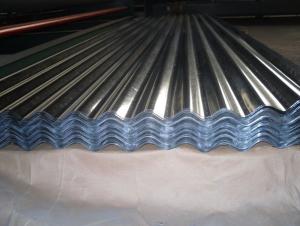

Corrugated steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Commodity | Hot dip galvanized steel coil and sheet |

Technical Standard: | JIS 3302 / ASTM A653 / EN10143 |

Grade | DX51D / DX52D/ DX53D/ S250,280,320GD |

Types: | Commercial / Drawing / Deep Drawing / Structural quality |

Width | 500/650/726/820/914 |

Thickness | 0.12-2.8mm |

Type of coating: | Galvanized |

Zinc coating | Z30-275g/m2 |

Surface Treatment | Chromed / Skin-pass/ Oiled/Slightly Oiled/ Dry/ Anti-fingerprint |

Surface structure: | Zero spangle / minimized spangle / regular spangle/ big spangle |

ID coil | 508mm or 610mm |

Coil weight | 3-8 MT per coil |

Package: | Properly packed for ocean freight exportation in 20''containers |

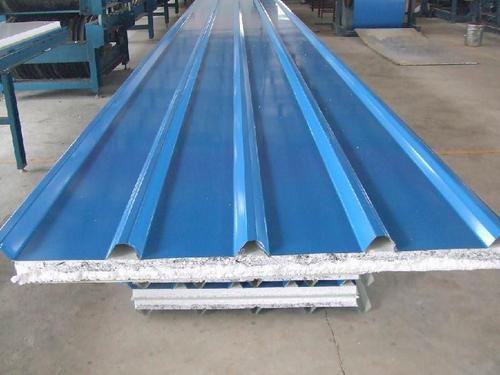

Application: | Industrial panels, roofing and siding for painting |

Price terms | FOB,CFR,CIF |

Payment terms | T/T or L/C |

Delivery time | Within 30 days |

Remarks | Insurance is all risks |

MTC will be handed on with shipping documents | |

We accept the third party certification test,such as SGS/BV |

Technical data :

Hot dipped galvanized coil Technical Data

Chemical Composition | ||||||

GRADE | C | Si | Mn | P | S | Ti |

SGCC/DX51D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

DX52D+Z | ≤0.10 | ≤0.50 | ≤0.60 | ≤0.10 | ≤0.030 | ≤0.020 |

SGCD/DX53D+Z | ≤0.10 | ≤0.30 | ≤0.50 | ≤0.05 | ≤0.030 | ≤0.020 |

SGCE/DX54D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

DX56D+Z | ≤0.10 | ≤0.30 | ≤0.30 | ≤0.03 | ≤0.020 | ≤0.020 |

Structural | ≤0.20 | ≤0.60 | ≤1.70 | ≤0.10 | ≤0.045 | |

|

|

|

|

|

| |

Hot dipped galvanized steel coil Mechanical Properties | |||

GRADE | Yield Strength MPa | Tensile Strength MPa | Elongation % |

SGCC(DX51D+Z) | ≥205 | ≥270 | - |

SGCD(DX53D+Z) | - | ≥270 | 38 |

SGCE(DX54D+Z) | - | ≥270 | 40 |

DX56D+Z | - | ≥270 | 42 |

- Q: What is the difference between a laminated and non-laminated steel sheet?

- Laminated steel sheets, which are produced by bonding multiple layers of steel with adhesive or resin, are known for their increased strength and durability. This lamination process enhances their resistance to bending, impact, and corrosion. Additionally, it reduces noise and vibration in applications like automotive bodies or construction materials. In contrast, non-laminated steel sheets consist of a single layer of steel without undergoing the lamination process. While these sheets are still robust and long-lasting, they may not possess the same level of resistance to bending, impact, and corrosion as laminated steel sheets. They are commonly used in roofing, siding, and general fabrication. The key distinction between laminated and non-laminated steel sheets lies in their composition and properties. Laminated steel sheets offer superior strength, durability, and resistance to various forces, making them ideal for demanding applications where structural integrity is crucial. On the other hand, non-laminated steel sheets are more cost-effective and suitable for applications where high strength and durability are not the primary requirements.

- Q: What is the thickness of the paint board?

- Paint plate generally in accordance with the "block" as the unit sales, not only as a wall decoration, doors, tables and chairs can do the shelves, cabinets bearing surface, the thickness of 1-2 cm in length, 50 - 120, 30 cm wide case is 55*30*1.5cm

- Q: Can steel sheets be used as a decorative material?

- Yes, steel sheets can be used as a decorative material. Due to their durability, versatility, and sleek appearance, steel sheets are often used in architectural and interior design projects to create modern and industrial aesthetics. They can be used for various applications such as wall cladding, countertops, furniture, and decorative accents, offering a contemporary and unique look to any space.

- Q: What is the difference between a brushed and polished steel sheet?

- A brushed steel sheet has a textured surface created by brushing the steel with a fine abrasive material, while a polished steel sheet has a smooth and reflective surface achieved by polishing the steel to a high shine.

- Q: What is the electrical resistivity of steel sheets?

- The electrical resistivity of steel sheets typically ranges from 10 to 20 micro-ohm meters.

- Q: What are the different types of steel sheet finishes for architectural applications?

- There are several different types of steel sheet finishes that are commonly used for architectural applications. These finishes not only enhance the aesthetic appeal of the steel sheets but also provide protection against corrosion and other environmental factors. 1. Mill Finish: This is the most basic type of finish, where the steel sheet is left as it comes from the mill. It has a dull, gray appearance and is typically used for applications where aesthetics are not a priority. 2. Brushed Finish: Also known as a satin finish, this type of finish is achieved by brushing the steel sheet with a fine abrasive material. It gives a smooth, linear texture to the surface, resulting in a contemporary and elegant appearance. 3. Polished Finish: This finish is achieved by polishing the steel sheet with abrasive materials until it becomes smooth and reflective. It provides a high-gloss, mirror-like appearance, making it suitable for applications that require a sophisticated and luxurious look. 4. Embossed Finish: In this finish, the steel sheet is pressed with embossing tools to create textured patterns or designs on the surface. This gives the sheet a unique and decorative appearance, making it ideal for architectural applications where visual interest is desired. 5. Patterned Finish: This finish involves applying a pattern or texture onto the steel sheet using various techniques like etching, laser cutting, or perforating. It creates a visually appealing surface with intricate designs, making it suitable for both functional and decorative purposes. 6. Powder Coated Finish: In this finish, a layer of dry powder paint is electrostatically applied to the steel sheet and then cured under heat. It provides a durable and vibrant finish, available in a wide range of colors and textures. This finish is highly resistant to chipping, scratching, and fading, making it ideal for exterior architectural applications. 7. Galvanized Finish: This finish is achieved by applying a layer of zinc coating onto the steel sheet through a process called galvanization. It provides excellent corrosion resistance, making it suitable for outdoor architectural applications where the steel sheet is exposed to harsh environments. Overall, the choice of steel sheet finish depends on the desired aesthetics, durability, and environmental conditions of the architectural application.

- Q: Can steel sheets be used for soundproofing purposes?

- Yes, steel sheets can be used for soundproofing purposes. They have good density and mass, which helps to block and absorb sound waves. Steel sheets can be effective in reducing noise transmission when properly installed and combined with other soundproofing materials like insulation or acoustic panels.

- Q: Can steel sheets be used for soundproofing or insulation?

- Yes, steel sheets can be used for soundproofing or insulation, but they are not as effective as other materials specifically designed for these purposes. Steel sheets have some natural soundproofing and insulating properties due to their density and ability to block sound and heat transfer to some extent. However, they are not as efficient as dedicated soundproofing or insulation materials such as acoustic panels or fiberglass insulation. Steel sheets can be used as an additional layer to improve the soundproofing or insulation properties of a structure, but they should be combined with other materials to achieve optimal results.

- Q: What are the different sheet metal joining techniques for steel sheets?

- Steel sheets can be joined using various techniques. Welding is commonly used, where the edges of the sheets are melted and fused together using heat and pressure. Different welding techniques like arc, spot, or laser welding can be used depending on the requirements. Riveting is another method, involving the use of metal fasteners called rivets. Holes are drilled in the sheets, and the rivets are inserted and deformed to secure the joint. This technique is suitable for structural applications due to its strength and durability. Bolting involves using bolts and nuts to connect the sheets. Holes are drilled, and bolts are inserted through them, with nuts tightened on the other side. Bolting allows for easy disassembly and reassembly, making it suitable for applications requiring frequent maintenance or repairs. Adhesive bonding is a technique where a strong glue is used to bond the sheets. The adhesive is applied between the surfaces, and pressure is applied for proper bonding. This method provides a clean and aesthetically pleasing joint without the need for drilling holes or using fasteners. Clinching is a cost-effective and quick method for joining steel sheets. It involves deforming the sheets using a punch and die, creating a mechanical interlock. This technique does not require additional materials and is suitable for various applications. The choice of joining technique depends on factors such as the specific application, required strength, durability, cost, and ease of assembly. Each technique has its own advantages and limitations.

- Q: What are the different fastening options for steel sheets?

- Some common fastening options for steel sheets include screws, nails, rivets, and welding. Screws are often used for attaching steel sheets to metal or wood frames, while nails are commonly used for temporary or lighter applications. Rivets provide a secure and permanent fastening method, often used in industrial or structural settings. Welding is another option, involving the fusion of steel sheets together using heat. Each fastening option has its advantages and is chosen based on the specific requirements of the application.

Send your message to us

Corrugated steel sheets

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords