Steel Mesh Sheet

Steel Mesh Sheet Related Searches

Sheet Of Stainless Steel Fine Plastic Mesh Sheet Wrought Iron Mesh Sheet Black Stainless Steel Sheet Stainless Steel Mesh Thin Stainless Steel Sheets Cold Rolled Steel Sheet Mesh Stainless Steel Screen Stainless Steel Mesh Screen Stainless Steel Sheet Near Me Magnesium Sheet Stainless Steel Sheeting Stainless Steel Screen Mesh Hot Rolled Steel Sheet Polished Aluminum Sheet Stainless Steel Screening Mesh Stainless Steel Sheet Metal Fabrication Steel Mesh Fencing Panels Stainless Steel Sheets Near Me Stainless Steel Sheets Price Rolled Aluminum Sheet 1 8 Stainless Steel Sheet Stainless Steel Sheets For Sale Woven Steel Mesh Panels Structural Plastic Sheets Aluminum Circle Sheet Stainless Steel Sheetmetal Aluminum Sheet Plate Ss Sheet Mesh Screen Stainless SteelSteel Mesh Sheet Supplier & Manufacturer from China

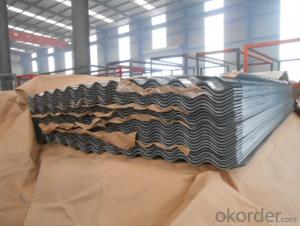

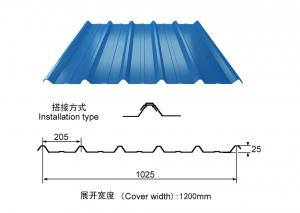

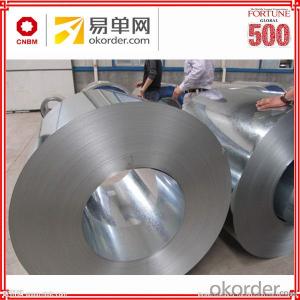

Steel Mesh Sheet, a versatile and robust material, is widely recognized for its durability and strength. Made from high-quality steel, these sheets are characterized by their uniform mesh pattern and resistance to corrosion, making them suitable for a variety of applications. They are commonly used in construction, agriculture, and industrial settings, where their ability to withstand heavy loads and harsh conditions is highly valued. Steel Mesh Sheets can be found in various forms, such as expanded metal, perforated sheets, and wire mesh, each serving specific purposes and meeting different requirements in their respective fields.In terms of usage, Steel Mesh Sheets are employed in a multitude of scenarios, from reinforcing concrete structures and providing safety barriers to serving as a base for walkways and platforms. Their flexibility allows them to be easily cut and shaped to fit various dimensions and configurations, making them an ideal choice for customized solutions. Whether it's for securing machinery, creating partitions, or offering protection against falling objects, Steel Mesh Sheets offer a reliable and cost-effective solution.

Okorder.com stands out as a leading wholesale supplier of Steel Mesh Sheets, boasting a vast inventory that caters to the diverse needs of customers across different industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that each Steel Mesh Sheet meets the highest standards of durability and performance. Their extensive range includes various mesh sizes, materials, and finishes, allowing customers to select the perfect Steel Mesh Sheet for their specific application.

Hot Products