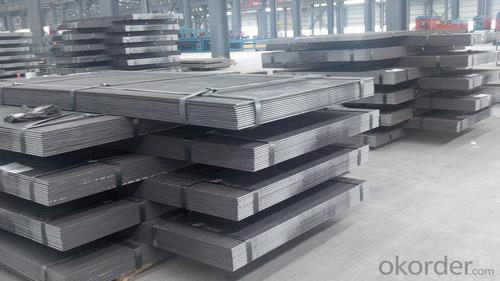

Hot Rolled Steel Plate Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot Rolled Steel Plate Q345

1. Hot Rolled & Annealing

2.Good Quality & Fast Delivery

3.Competitive Price & Nice Service

hot rolled steel plate

Standard:ASTM AISI BS GB JIS DIN Thickness:3.0-250mm

Material: S235JR, SS400, S355JR, A36

ASTM A283/A283M-03 Grade D

ASTM A572/A572M-04 Grade 50(345)

JIS G3101-2004 SS400

JIS G3135-1986 SPFC 590

EN 10025/2-2004 S235JR or S235JO or S235J2

EN 10025/2-2004 E335 or S335JR or S335JO or S335JZ or S335KZ or S335NL

Specification:

THICKNESS:2mm-120mm

WIDTH:1250mm-3000mm

LENGTH:1500mm-18000mm

1.0/1.5*1000*C, 1.5*1250/1500*C

2.90*1250/1500*C, 3.75*1250/1500*C

4.50*1250/1500*C, 4.75*1250/1500*C

5.00*1250/1500*C, 5.25*1250/1500*C

5.50*1250/1500*C, 5.75*1250/1500*C

6.00*12501500*C, 7.25*1250/1500*C

7.50*1250/1500*C, 7.75*1250/1500*C

8.0*1250/1500*C

9.25/9.50/9.75/11.25/11.50/11.75*1500*C

High quality: smooth, straight, bright, with no blur on both ends

Feature: Heat conduction, excellent freezing, even structure with pressure resistance, Good mechanical properties

- Q: Can steel sheets be recycled without losing their properties?

- Yes, steel sheets can be recycled without losing their properties. Steel is a highly recyclable material, and the recycling process does not affect its inherent properties such as strength, durability, and corrosion resistance. Recycling steel sheets helps conserve natural resources, reduces energy consumption, and minimizes environmental impact.

- Q: How do steel sheets perform in fire-rated applications?

- Due to their high melting point and excellent structural integrity, steel sheets are highly effective in fire-rated applications. When exposed to fire, steel sheets retain their strength and stability, making them a dependable choice for fire-resistant construction. Furthermore, steel sheets do not contribute to the spread of fire or the release of harmful fumes, thereby enhancing the safety of occupants during a fire incident. In addition, steel sheets offer exceptional thermal insulation, preventing the transfer of heat from the fire to other parts of the building. This characteristic enables the containment of fires and minimizes the resulting damage. In conclusion, utilizing steel sheets in fire-rated applications offers a sturdy and efficient solution for fire protection in buildings.

- Q: Can steel sheets be used for manufacturing industrial equipment?

- Indeed, the utilization of steel sheets for the production of industrial equipment is possible. Due to its robustness, longevity, and resistance to deterioration, steel is a multifaceted and extensively employed substance in various industries. When it comes to the manufacturing of industrial equipment, steel sheets can be effortlessly shaped, cut, and formed into diverse components. These components are essential for the creation of machinery, tools, storage tanks, conveyors, and structural supports. Furthermore, steel sheets possess exceptional load-bearing capacity, rendering them suitable for demanding applications in sectors like construction, automotive, aerospace, energy, and manufacturing. Moreover, steel sheets can be subjected to treatments or coatings to augment their properties, such as enhancing their resistance to heat, chemicals, or wear. In conclusion, due to their durability, adaptability, and dependability, steel sheets are an immensely popular choice for the manufacturing of industrial equipment.

- Q: What are the different edge treatments available for steel sheets?

- Some common edge treatments available for steel sheets include sheared edges, deburred edges, rolled edges, chamfered edges, and beveled edges.

- Q: What are the different methods of joining steel sheets together?

- There are several methods of joining steel sheets together, each with its own advantages and applications. Some of the common methods include: 1. Welding: Welding is a widely used method for joining steel sheets. It involves melting the edges of the sheets and fusing them together using heat. There are different types of welding processes such as arc welding, gas welding, and spot welding, each suited for specific applications. 2. Riveting: Riveting is a mechanical method of joining steel sheets using metal fasteners called rivets. The rivets are inserted through pre-drilled holes in the sheets and then hammered or pressed to secure them in place. Riveting is known for providing strong and durable joints. 3. Bolting: Bolting involves using bolts and nuts to hold steel sheets together. Holes are drilled through the sheets, and then bolts are inserted from one side, with nuts tightened on the other side to secure the joint. Bolting is quick, easy to assemble, and allows for disassembly if needed. 4. Adhesive bonding: Adhesive bonding uses specialized adhesives to join steel sheets together. The adhesive is applied between the surfaces to be joined and forms a strong bond as it cures. This method is commonly used in industries where welding can cause distortion or is not feasible due to the materials involved. 5. Mechanical fastening: Mechanical fasteners like screws, self-tapping screws, or nails can be used to join steel sheets together. These fasteners create a strong connection by penetrating the sheets and holding them in place. Mechanical fastening is relatively quick and doesn't require any specialized equipment. 6. Clinching: Clinching is a cold forming process that involves joining steel sheets by deforming the material without any external heat source. It involves pressing the sheets together and forming a mechanical interlock. Clinching is commonly used in the automotive industry due to its high-speed production capabilities and joint strength. Each method has its own advantages based on factors such as joint strength, ease of assembly, cost, and specific application requirements. The choice of joining method depends on the purpose of the joint, material properties, and environmental conditions the joint will be subjected to.

- Q: How do steel sheets compare to other sheet materials like aluminum or stainless steel?

- Steel sheets have several advantages over other sheet materials like aluminum or stainless steel. Firstly, steel sheets are known for their exceptional strength and durability. They can withstand heavy loads and are resistant to impact, making them ideal for applications that require high strength and stability. Aluminum sheets, on the other hand, are relatively softer and less resistant to impacts, making them more suitable for lightweight applications. Secondly, steel sheets offer excellent corrosion resistance. While stainless steel sheets also possess this characteristic, steel sheets can be coated with protective layers or galvanized to enhance their corrosion resistance even further. This makes steel sheets more suitable for outdoor applications or environments with high humidity or exposure to harsh chemicals. Aluminum sheets, on the contrary, are prone to corrosion and typically require additional coating or treatment for protection. Moreover, steel sheets are more cost-effective compared to aluminum or stainless steel sheets. Steel is widely available and has a lower production cost, making steel sheets a more affordable option for many industries. Aluminum sheets, on the other hand, tend to be more expensive due to the higher cost of the raw material and the manufacturing process involved. Stainless steel sheets are also relatively expensive due to the additional alloying elements present in their composition. Lastly, steel sheets offer excellent fire resistance. They have a high melting point and do not easily catch fire or contribute to the spread of flames. This makes steel sheets the preferred choice for applications that require fire safety, such as construction or transportation. In summary, steel sheets stand out due to their exceptional strength, durability, corrosion resistance, cost-effectiveness, and fire resistance. While aluminum and stainless steel sheets have their own unique properties and applications, steel sheets are often favored for their superior overall performance in various industries.

- Q: What is the price range of steel sheets?

- The cost of steel sheets can differ based on various factors, including the steel's type and grade, the sheet's thickness and size, and the prevailing market conditions. Typically, steel sheets can be priced between $0.60 and $1.50 per pound. Nevertheless, it is crucial to note that these figures are only approximate and subject to frequent modifications due to fluctuations in the steel market and other economic elements. To obtain the most precise and current pricing details for steel sheets, it is recommended to consult local suppliers or utilize online platforms.

- Q: What are the different thickness options available for steel sheets?

- The thickness options available for steel sheets vary, depending on the specific requirements and applications. Common thicknesses range from 0.4 mm (thin gauge) to 6 mm (thick gauge), with intermediate options such as 1.5 mm, 3 mm, and 4.5 mm also available. These different thicknesses offer flexibility in terms of strength, durability, and suitability for various industrial and construction purposes.

- Q: Can steel sheets be used for electrical enclosures or cabinets?

- Yes, steel sheets can be used for electrical enclosures or cabinets. Steel is a commonly used material for such applications due to its durability, strength, and ability to provide electrical grounding. It also offers protection against external elements and acts as a shield for electrical components inside the enclosure or cabinet.

- Q: What is the electromagnetic steel plate in the generator?

- As the core material, the magnetic conductivity is the core.As for the protection of heat resistant copper wire, the argument is not very good, because under normal circumstances, copper heat than iron core heat greater.

Send your message to us

Hot Rolled Steel Plate Q345

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords