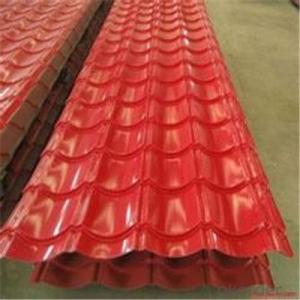

Prepainted Galvanized Corrugated Steel Plate Sheet:roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Packaging & Delivery

| Packaging Detail: | Standard package for export |

| Delivery Detail: | 15 days after receipt the deposit or Original L/C |

Specifications

Prepainted roofing steel sheets

1. Thickness: 0.15mm---1.5mm

2. Width:800,900,1200,1220,1250mm

3.can be prepainted

Commodity | color coated galvanized steel plate |

Material | Galvanized steel sheet Galvalume steel sheet Pre-painted galvanized sheet |

Coating | PE,PVDF,galvanized(30-300g),galvalume (AZ80) |

Model No. | YX25-207-828 |

Sheet Thickness | 0.15---1.5mm |

Sheet Peak Height | 25mm |

Sheet Peak Spacing | 207mm |

Width | 800mm,900mm,1000mm |

Length | any length,according to the transportation,generally less than 12m |

Color | Standard color: red,blue,white grey Special color: according to RAL color |

Characteristic | 1 weatherproof 2 heating insulation 3 fireproof 4 anti-rust 5 sound insulation 6 long life span: more than 25 years

|

Packing | Plastic film,pallet or as your requests |

Delivery time | 15 days |

Payment | T/T,L/C |

Images:

- Q: What kind of material does ordinary steel plate refer to in steel market?

- And because of the common strength, there is a single carbon steel plate is made, then the internal molecular interactions is very single, which makes the steel in strength is very limited, there is no better development. But the alloy steel plate is different, because this kind of steel plate because has joined many other elements, this also causes its internal molecular structure to become extremely complex, simultaneously its internal molecular force also becomes extremely strong. It also gives the plate greater in strength increased, and the alloying elements of the steel sheet is fixed on the strength of it development is limitless.

- Q: Can steel sheets be used for manufacturing electrical enclosures?

- Yes, steel sheets can be used for manufacturing electrical enclosures. Steel is a commonly used material for constructing electrical enclosures due to its durability, strength, and ability to provide necessary protection for electrical components. The use of steel sheets ensures that the enclosure is sturdy and can withstand various environmental conditions. Additionally, steel offers good electromagnetic shielding properties, which can help protect sensitive electronic equipment from interference. Steel sheets are also fire-resistant, making them suitable for manufacturing enclosures that need to meet safety regulations. Overall, steel sheets are a reliable choice for manufacturing electrical enclosures due to their characteristics and suitability for the purpose.

- Q: Can steel sheets be used for modular construction or prefabricated buildings?

- Modular construction and prefabricated buildings can utilize steel sheets for their construction. The strength, durability, and versatility of steel make it a popular choice for this type of construction. Steel sheets can be used to build the framework, walls, and roof of prefabricated buildings. Modular construction involves fabricating building components in a controlled factory environment. Steel sheets can be easily cut, shaped, and welded to create customized building modules. These modules can then be transported to the construction site and quickly assembled. The use of steel sheets ensures precision and consistency in the manufacturing process, resulting in high-quality components. Steel's excellent strength-to-weight ratio makes it ideal for modular construction. Using steel sheets allows for lightweight yet sturdy building modules. This is advantageous for transportation and installation, as it reduces the overall weight and cost associated with shipping and lifting the modules. Furthermore, steel is a durable material that can withstand various weather conditions and environmental factors. It is resistant to fire, termites, and rot, making it a reliable choice for long-lasting prefabricated buildings. Steel sheets can also be treated to enhance their corrosion resistance, protecting the building against rust and deterioration. In addition to its strength and durability, steel offers design flexibility. Steel sheets can be easily manipulated to create different shapes and forms, allowing for diverse architectural styles and configurations. This versatility makes steel an attractive option for architects and builders looking to create aesthetically pleasing and functional prefabricated buildings. Overall, steel sheets are suitable for modular construction and prefabricated buildings due to their strength, durability, versatility, and design flexibility. Using steel in this construction method enables efficient manufacturing, easy transportation, and quick assembly, resulting in cost-effective and high-quality buildings.

- Q: How is the weight of the steel plate calculated?

- Steel plate by thickness, thin steel plate <4 mm (thinnest 0.2 mm), thick steel plate 4~60 mm, extra thick steel plate 60~115 mm.The steel plate is divided into hot-rolled and cold-rolled parts according to rolling.The width of the sheet is 500~1500 mm; the thickness is 600~3000 mm. According to the type of steel sheet, ordinary steel, stainless steel, alloy steel, spring steel, stainless steel, tool steel, heat-resistant steel, bearing steel, silicon steel and industrial pure iron sheet; according to professional use, with drums board, enamel board, bulletproof plate; surface coating and plating, plating with zinc thin plate, tin plate, plating lead sheet, plastic composite plate.

- Q: What is the average weight of galvanized steel sheets?

- The average weight of galvanized steel sheets can vary depending on their dimensions and thickness. However, a common gauge for galvanized steel sheets is between 18 and 26 gauge, with sizes ranging from 0.036 inches to 0.0179 inches thick. On average, a 18 gauge galvanized steel sheet can weigh approximately 5.625 pounds per square foot, while a 26 gauge sheet may weigh around 3.125 pounds per square foot. It is important to note that these numbers are approximate averages and individual sheets may vary slightly in weight.

- Q: Can steel sheets be formed into complex shapes?

- Yes, steel sheets can be formed into complex shapes through various metalworking processes such as bending, rolling, stamping, and laser cutting. These processes allow the steel sheets to be manipulated and transformed into intricate and custom shapes, meeting the specific design requirements. The malleability and strength of steel make it possible to form it into complex shapes without compromising its structural integrity. These capabilities are widely utilized in industries such as automotive, aerospace, construction, and manufacturing, where complex and precise components are required.

- Q: Are steel sheets suitable for agricultural machinery?

- Yes, steel sheets are suitable for agricultural machinery due to their durability, strength, and ability to withstand harsh conditions commonly encountered in farming operations.

- Q: Can steel sheets be used for manufacturing doors or windows?

- Yes, steel sheets can be used for manufacturing doors or windows. Steel is a durable and strong material that is commonly used in construction, including for doors and windows. It provides strength, security, and can be designed in various styles to meet different aesthetic preferences.

- Q: How do steel sheets perform in low-temperature environments?

- Steel sheets perform well in low-temperature environments due to their exceptional strength, durability, and resistance to fracture. Unlike other materials, steel retains its mechanical properties even at extremely low temperatures, making it a reliable choice for various applications in cold climates or industries like construction, transportation, and energy.

- Q: Are the steel sheets resistant to atmospheric corrosion?

- Yes, steel sheets are generally resistant to atmospheric corrosion. However, the level of resistance can vary depending on the specific type of steel used and the environmental conditions it is exposed to. For instance, stainless steel sheets are highly resistant to atmospheric corrosion due to the presence of chromium, which forms a protective oxide layer on the surface. On the other hand, carbon steel sheets may be more susceptible to corrosion if they are not properly coated or treated. Additionally, the presence of pollutants, humidity, and other factors in the atmosphere can also affect the corrosion resistance of steel sheets. Therefore, it is important to consider these factors and choose the appropriate type of steel and protective measures to ensure long-term resistance to atmospheric corrosion.

Send your message to us

Prepainted Galvanized Corrugated Steel Plate Sheet:roofing sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 30 m.t.

- Supply Capability:

- 500000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords