Zinc Coating Galvanized Corrugated Steel Iron Zinc Roof Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Description of Corrugated Iron Sheet:

1) Capacity: about 15,000 tons per month for sheet product.

2) Standard: JIS G3302 1998, ASTM A653M/A924M 2004, all according to the customer's request

3) Thickness: 0.13mm-0.5mm

4) Width: 400mm-1000mm

5) Length: We can adjust the length according to your request

6) Zinc Coating Weight: 60g/m2-275g/m2

Specifications of Corrugated Iron Sheet:

Standards: GB, JIS3312 and ASTM

Materials: SGCC, Q195-Q235B, SPCC, DC01, DX51D+Z and more

Thicknesses: 0.23-1.0MM

Widths: 600-1200mm

Zinc coating: 80 to 275g/m²

Features of Corrugated Iron Sheet:

Spangle: Regular spangle, minimized spangle and zero spangle

Hardness: Full hard, normal

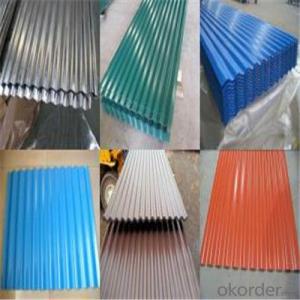

Color: RAL, or other series

Surface Protection: PE, PVC, PVDF, SMP, HDP, etc.

Min trial order 10 tons each thickness, 1x20' per delivery.

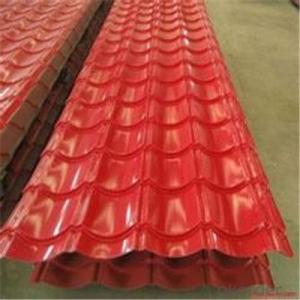

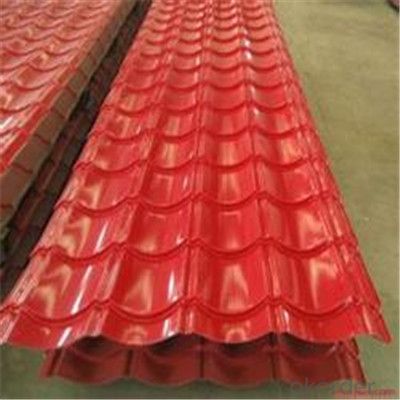

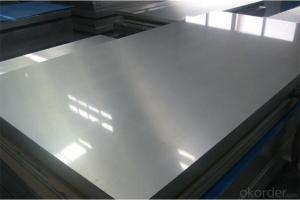

Images of Corrugated Iron Sheet:

FAQ:

1. What's the Delivery port?

The main ports are Qingdao and Tianjin, we also can deliver to other ports to meet your requirements

2. How long is the lead time?

Delivery time: 45 days after order confirmed.

3. What payment term do you accept?

Payment: T/T or L/C at sight.

- Q: How do steel sheets handle static electricity?

- Steel sheets are generally good conductors of electricity, including static electricity. This means that when static electricity is present, it will easily flow through the steel sheet and dissipate, reducing the likelihood of any buildup or discharge of static electricity.

- Q: Can steel sheets be used for insulation cladding?

- No, steel sheets are not typically used for insulation cladding. Insulation cladding is usually made of materials with thermal insulation properties such as foam boards, mineral wool, or fiberglass. These materials are chosen for their ability to reduce heat transfer and improve energy efficiency. Steel sheets, on the other hand, are commonly used for structural purposes or as a protective layer due to their strength and durability. While steel sheets can provide some level of protection, they do not possess the necessary insulation properties to effectively prevent heat or cold transfer. Therefore, it is recommended to use appropriate insulation materials specifically designed for cladding purposes.

- Q: What is the difference between a satin and mirror finish steel sheet?

- The main difference between a satin and mirror finish steel sheet lies in their appearance. A satin finish has a smooth, brushed texture with a muted sheen, while a mirror finish has a highly reflective, glossy surface that resembles a mirror. The satin finish is achieved through a process of sanding or brushing the steel, creating fine lines or grain, whereas a mirror finish requires additional polishing and buffing to achieve its reflective quality.

- Q: What are the common sizes of steel sheets available?

- Steel sheets are available in a variety of sizes to meet the diverse needs of different industries and applications. The common sizes of steel sheets can vary depending on the manufacturer and the specific requirements of the customer. However, there are some standard sizes that are widely available in the market. The most common sizes of steel sheets include: 1. 4 feet by 8 feet: This is one of the most popular sizes and is widely used in construction, manufacturing, and automotive industries. It provides a large surface area for various applications, including roofing, siding, and fabrication. 2. 4 feet by 10 feet: This size is similar to the 4 feet by 8 feet sheets but offers a larger surface area, making it suitable for larger projects that require more material. 3. 5 feet by 10 feet: This size provides an even larger surface area than the 4 feet by 10 feet sheets, making it ideal for industrial applications that require extensive coverage. 4. 6 feet by 12 feet: This is a larger size that is commonly used in heavy-duty applications, such as shipbuilding, construction of large structures, and industrial machinery. It's important to note that these are just some of the common sizes available, and there are many other sizes offered by manufacturers to cater to specific requirements. Additionally, steel sheets can also be custom-cut to fit specific dimensions, allowing for greater flexibility and tailoring to individual project needs.

- Q: Are steel sheets suitable for swimming pool construction?

- Yes, steel sheets are suitable for swimming pool construction. Steel sheets are known for their strength and durability, making them an excellent choice for building swimming pools. They provide a stable and sturdy structure that can withstand the weight of the water and the pressure exerted on the pool walls. Additionally, steel sheets can be easily molded and welded into various shapes and sizes, allowing for customization and flexibility in pool design. Moreover, steel is resistant to corrosion, which is crucial for maintaining the integrity of the pool over time, especially when exposed to chlorinated water. Therefore, steel sheets are a reliable and popular option for swimming pool construction.

- Q: Are steel sheets suitable for mining or construction equipment?

- Yes, steel sheets are suitable for mining or construction equipment. Steel is a durable and strong material, making it ideal for heavy-duty machinery used in mining or construction. It provides excellent structural integrity and can withstand harsh environmental conditions, making it a reliable choice for equipment in these industries.

- Q: Can steel sheets be used for fencing applications?

- Yes, steel sheets can be used for fencing applications. Steel sheets are commonly used for fencing due to their durability, strength, and resistance to harsh weather conditions. They provide a sturdy and secure barrier, making them suitable for various fencing applications such as residential, commercial, industrial, and agricultural purposes.

- Q: What is the process of manufacturing steel sheets?

- The process of manufacturing steel sheets involves several steps. First, the raw materials for steel production, which include iron ore, coal, and limestone, are obtained. These materials are then processed in a blast furnace to create molten iron. The molten iron is then refined in a basic oxygen furnace or an electric arc furnace, where impurities are removed and alloying elements are added to achieve the desired steel composition. Once the steel is refined, it is cast into slabs or billets, which are then reheated in a furnace to a temperature suitable for rolling. The reheated steel is then passed through a series of rolling mills, where it is shaped and reduced in thickness to form a continuous sheet. The rolling process involves multiple passes through the mills, with each pass gradually reducing the thickness of the steel and improving its properties. After the rolling process, the steel sheets are often pickled and treated with various coatings or finishes to improve their surface quality and corrosion resistance. Finally, the sheets are cut into specific sizes and may undergo additional processing, such as tempering or annealing, to further enhance their mechanical properties. Overall, the process of manufacturing steel sheets involves a combination of refining, casting, rolling, and finishing processes to produce high-quality sheets that meet the desired specifications.

- Q: Can steel sheets be used in construction?

- Yes, steel sheets can definitely be used in construction. Steel sheets are commonly used in construction projects due to their strength, durability, and versatility. They can be used in various applications such as roofing, walls, flooring, and structural components. Steel sheets are known for their high tensile strength, which makes them capable of withstanding heavy loads and extreme weather conditions. Additionally, steel sheets are fire-resistant, termite-resistant, and have a long lifespan, making them a reliable choice for construction projects. Furthermore, steel sheets can be easily fabricated, allowing for customization and flexibility in design. Overall, steel sheets are an excellent choice for construction as they provide structural integrity, durability, and design versatility.

- Q: How much is one meter for laser cutting steel plates?

- The above price is for low carbon steel. The price of stainless steel is lower than that of low carbon steel. Mainly nitrogen, a large amount.Of course, the specific price with the processing capacity of the size, the shape of the parts (compare all holes can not be completely by the meter, whether to count) freight, whether it is with material processing have a great relationship.

Send your message to us

Zinc Coating Galvanized Corrugated Steel Iron Zinc Roof Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 200 m.t.

- Supply Capability:

- 1000000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords