Stainless Steel Sheet for Construction Field

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Stainless Steel Sheet

Description for Stainless steel Sheet:

Description | steel sheet,hot rolled steel sheet,cold rolled stainless steel sheet, steel sheet,sheet,steel plate |

Material | 201,202,304,304L,309S,310S,316,316L,316Ti,317L,321,347H,409,409L,410,410S,420,430,etc. |

Thickness | From 0.3mm to 100mm |

Width | 1000mm,1219mm,1250mm,1500mm,1800mm,2200mm or be cut as your requirement |

Length | 2000mm,2438mm,2500mm,6000mm,6096mm or be cut as your requirement |

Standard | ASME, ASTM, EN ,BS,GB,DIN, JIS etc |

Main Features: steel sheet applies to construction field, ships building industry, petroleum & chemical industries, war and electricity industries, food processing and medical industry, boiler heat exchanger, machinery and hardware fields.

| |

Packaging | By bulk vessel OR By container OR as customers' requirement |

Delivery time | 2-3 weeks after reciept the L/C OR T/T |

Quality | No.1 |

Productivity | 1000 tons/mouth |

Note | Our company has cooperative relation between the domestic agents. Stainless steel sheet can be made accordingto the customers requirements. Fasten delivery. Quality assured. |

Remark | If you have any question,please feel free let us know. |

FAQ:

Why Should You Choose Us?

Profession in construction filed

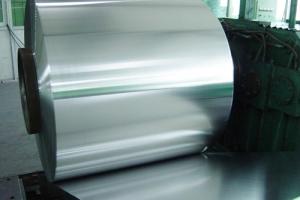

With full complete production line like steel coil, wire rope, conveyor belt etc

Competitive price, superior quality, strong finance abilty

Strong and Stable qualification

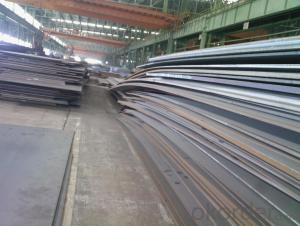

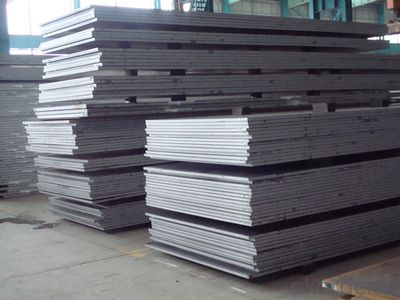

Picture:

- Q: What are the insulation properties of steel sheets?

- Compared to other commonly used insulation materials like fiberglass or foam, steel sheets have relatively poor insulation properties. This is because steel is an excellent conductor of heat and electricity, possessing high thermal conductivity. Consequently, steel sheets are ineffective in preventing heat transfer and are not typically used as standalone insulation materials. Nonetheless, steel sheets can still offer some insulation benefits when utilized alongside other insulating materials. For example, they can serve as a protective layer or cladding, enhancing the durability and fire resistance of insulation systems. Additionally, they can function as a radiant barrier, redirecting heat away from buildings and reducing heat gain in warm climates. To summarize, although steel sheets themselves do not possess exceptional insulation properties, they can contribute to improving overall insulation performance when combined with other insulating materials or applied in specific scenarios such as radiant barriers.

- Q: How do steel sheets compare to plastic sheets?

- Steel sheets are generally stronger, more durable, and have a higher heat resistance compared to plastic sheets. They are better suited for heavy-duty applications, such as construction and industrial uses, where strength and durability are crucial. Plastic sheets, on the other hand, are lightweight, flexible, and cost-effective. They are commonly used for applications where weight and cost are important factors, such as packaging, signage, and some consumer goods. Ultimately, the choice between steel and plastic sheets depends on the specific requirements and intended use of the sheets.

- Q: How are steel sheets tested for quality and performance?

- Steel sheets are tested for quality and performance through various methods such as mechanical testing, chemical analysis, and visual inspection. Mechanical testing involves subjecting the steel sheets to stress, tension, and hardness tests to determine their strength and durability. Chemical analysis is conducted to assess the composition and purity of the steel, ensuring it meets the required standards. Visual inspection checks for any surface defects, such as cracks, scratches, or unevenness in the steel sheets. These comprehensive testing methods ensure that steel sheets meet the desired quality and performance criteria.

- Q: What is the typical fatigue strength of a steel sheet?

- The typical fatigue strength of a steel sheet depends on various factors such as the steel grade, thickness, surface condition, and the specific loading conditions. It is usually determined through fatigue tests conducted under controlled laboratory conditions. Therefore, it is difficult to provide a specific value without considering these variables.

- Q: Can steel sheets be used for storage tanks or containers?

- Yes, steel sheets can be used for storage tanks or containers. Steel is a durable and strong material that can withstand high pressure and is resistant to corrosion, making it suitable for storing various substances and materials.

- Q: How do I print the steel plate?

- Because in the stencil lettering all strokes forming holes, printing pigment through the hole leakage in the following paper

- Q: How do steel sheets perform in terms of air permeability?

- Steel sheets are not permeable to air, meaning they do not allow air to pass through them easily.

- Q: How much is a steel sheet per square meter?

- If the purchase amount is large, usually by tonnage valuation, such as carbon steel is about 5 tons Qianduoyi, 304 stainless steel more than 10000, of course, the price is floating on the market according to the.

- Q: Can steel sheets be used for metal fencing?

- Yes, steel sheets can be used for metal fencing. Steel sheets are commonly used in the construction of metal fences due to their durability, strength, and ability to withstand harsh weather conditions. They provide a solid and secure barrier, making them an excellent choice for fencing applications.

- Q: Can steel sheets be recycled after their useful life?

- Yes, steel sheets can be recycled after their useful life. Steel is one of the most commonly recycled materials in the world, and the recycling process for steel sheets involves melting them down to create new steel products. This not only helps conserve natural resources but also reduces waste and the environmental impact of steel production.

Send your message to us

Stainless Steel Sheet for Construction Field

- Loading Port:

- Qingdao

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords