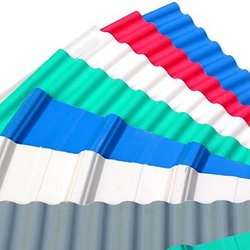

Prepainted Galvanised Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

General Information Of Prepainted Galvanized Steel

With GI as base metal, after pretreatment (degrease and chemical treatment) and liquid dope with several layers of color, then after firing and cooling, finally the plate steel is called pre-painted galvanized steel. Pre-painted galvanized steel is good capable of decoration, molding, corrosion resistance. It generally displays superior workability, durability and weather resistance.

Thickness 0.23-1.2mm (BMT) |

Zinc Coating 80-275g/m2 |

Color According to RAL color fan |

Internal Diameter 508mm or 610mm |

Coil Weight 4-8MT |

Quality Commercial and structural quality |

Paint Polyester paint for topside, epoxy for reverse |

Standard JIS G 3312, ASTM A755M, EN 10169 |

Base Steel Grade SGCC,SGCD,DX51D+Z,DX52D+Z;S200GD,S220GD, S280GD,S350GD,CS,FS,SS |

Chemical Composition Of Prepainted Galvanized Steel

C | Si | Mn | P |

0.04-0.06% | 0.01-0.03% | 0.18-0.22% | 0.014-0.016% |

Technical Data Of Prepainted Galvanized Steel

Yield Strength | (Mpa) 280-320 |

Tensile Strength | (Mpa) 340-390 |

Elongation | 20%-30% |

Reverse Impact | 9J |

T-bending | ≥2T |

Pencil Hardness | ≥2H |

Duration Of Salt Spray Test | 500 H |

Bending At 180 Degree | No crack, purling and fraction |

Application Of Prepainted Galvanized Steel

Outdoor:

roof, roof structure, surface sheet of balcony, frame of window, door, door of garage, roller shutter door, booth, Persian blinds, cabana, etc.

In door:

door, isolater, frame of door, light steel structure of house, home electronic appliances, etc.

Packaging & Delivery Of Prepainted Galvanized Steel

Anti-damp paper inside full wrapped with plastic film, iron sheet outside on wooden pallet in 20 feet container with 25mt.

- Q: Can steel sheets be used for manufacturing shipping pallets?

- Yes, steel sheets can be used for manufacturing shipping pallets. Steel sheets provide durability, strength, and resistance to damage, making them suitable for heavy-duty applications like shipping pallets.

- Q: Are the steel sheets suitable for food-grade applications?

- Yes, steel sheets are suitable for food-grade applications.

- Q: How do steel sheets perform in thermal conductivity?

- Steel sheets have high thermal conductivity, meaning they are efficient at transferring heat. This property makes them ideal for applications that require heat transfer, such as in heating systems, cookware, and industrial processes.

- Q: Are steel sheets suitable for outdoor applications?

- Yes, steel sheets are suitable for outdoor applications. Steel is highly durable, weather-resistant, and can withstand harsh environmental conditions, making it an excellent choice for outdoor usage.

- Q: Are steel sheets suitable for roofing?

- Yes, steel sheets are suitable for roofing. Steel is a durable and strong material that can withstand harsh weather conditions, such as heavy rain, snow, and strong winds. It is also resistant to fire, pests, and rot, making it a reliable choice for long-term roofing solutions. Steel sheets are lightweight and easy to install, reducing labor and installation costs. Additionally, they are available in a variety of colors and finishes, allowing for customization to match the aesthetic of any building. Overall, steel sheets provide excellent protection and longevity, making them a popular choice for roofing applications.

- Q: What are the different types of coatings available for steel sheets?

- There are several types of coatings available for steel sheets, including galvanized coatings, zinc coatings, tin coatings, aluminum coatings, and polymer coatings. Each type of coating offers unique properties and benefits, such as corrosion resistance, improved durability, enhanced aesthetics, and increased protection against environmental factors. The choice of coating depends on the specific application and desired characteristics of the steel sheets.

- Q: Are steel sheets resistant to bending or deformation?

- Yes, steel sheets are highly resistant to bending or deformation due to their inherent strength and rigidity.

- Q: Are steel sheets vulnerable to UV radiation?

- Yes, steel sheets are generally not vulnerable to UV radiation.

- Q: Are the steel sheets resistant to atmospheric corrosion?

- Generally, steel sheets possess resistance against atmospheric corrosion. However, the degree of resistance may differ depending on the specific steel type employed and the environmental conditions it encounters. For example, stainless steel sheets exhibit high resistance owing to the inclusion of chromium, which generates a safeguarding oxide layer on the surface. Conversely, carbon steel sheets might be more vulnerable to corrosion if they lack proper coating or treatment. Moreover, the presence of pollutants, humidity, and other atmospheric aspects can also impact the corrosion resistance of steel sheets. It is, therefore, crucial to take into account these factors and select the suitable steel type and protective measures to ensure enduring resistance against atmospheric corrosion.

- Q: What factors affect the cost of steel sheets?

- Several factors affect the cost of steel sheets, including the current market demand and supply, raw material prices, manufacturing and processing costs, transportation and logistics expenses, as well as any applicable trade tariffs or taxes. Additionally, factors such as the type and quality of steel, size and thickness of the sheets, as well as any special finishes or coatings required, can also impact the overall cost.

Send your message to us

Prepainted Galvanised Corrugated Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords