Galvanized Corrugated Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Zinc Coating Steel Building Roof Walls

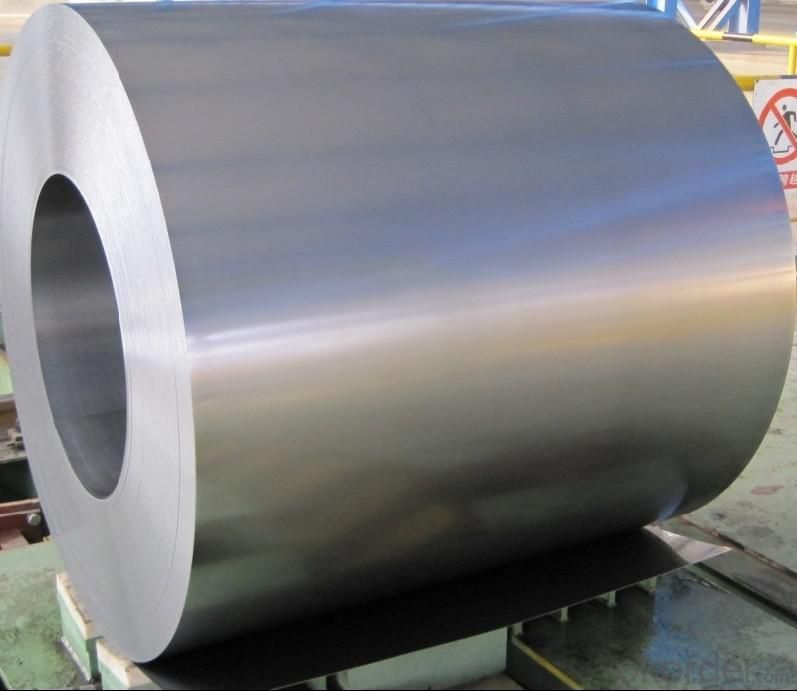

1.Structure of Hot-Dip Galvanized Steel Sheet Description:

Hot-dip galvanized steel coils are available with a pure zinc coating through the hot-dip galvanizing process. It offers the economy, strength and formability of steel combined with the corrosion resistance of zinc. The hot-dip process is the process by which steel gets coated in layers of zinc to protect against rust. It is especially useful for countless outdoor and industrial applications. Production of cold formed corrugated sheets and profiles for roofing, cladding, decking, tiles, sandwich walls, rainwater protective systems, air conditioning duct as well as electrical appliances and engineering.

2.Main Features of the Hot-Dip Galvanized Steel Sheet:

• Excellent process capability

• Smooth and flat surface

• Workability, durability

• Excellent anticorrosive property

• High strength

• Good formability

• Good visual effect

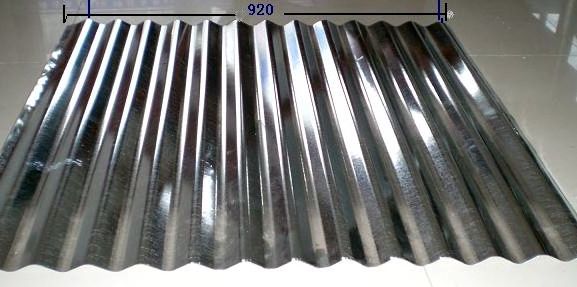

3.Hot-Dip Galvanized Steel Sheet Images

4.Hot-Dip Galvanized Steel Sheet Specification

Standard: ASTM, JIS,EN

Grade: CS, DX51D+Z,SGCC, SS 230~550,S220GD+Z~S550GD+Z, SGC340~SGC570

Thickness: 0.1mm~5mm

Width: max 2000mm

Coil weight:3-12 MT

Coil ID:508/610mm

Surface structure: zero spangle, regular spangle or minimum spangle

Surface treatment: Chromate treatment, Oiled/dry, skinpassed/non-skinpassed

Packing: Standard seaworthy export package

Technology test results:

| Processability | Yield strength | Elongation % | Elongation % | 180°cold-bending |

| Common PV | - | 270-500 | - | d=0,intact,no zinc removal |

| Mechanical interlocking JY | - | 270-500 | - | d=0,intact,no zinc removal |

| Structure JG | >=240 | >=370 | >=18 | d=0,intact,no zinc removal |

| Deep drawn SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

| EDDQ SC | - | 270-380 | >=30 | d=0,intact,no zinc removal |

5.FAQ of Hot-Dip Galvanized Steel Sheet

We have organized several common questions for our clients,may help you sincerely:

1.How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2.How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3. How long can we receive the product after purchase?

Usually within thirty working days after receiving buyer’s advance payment or LC. We will arrange the factory manufacturing as soon as possible. The cargo readiness usually takes 15-30 days, but the shipment will depend on the vessel situation.

- Q: How are steel sheets protected from rust and corrosion?

- Steel sheets are protected from rust and corrosion through a process called galvanization, which involves coating the sheets with a layer of zinc. This zinc layer acts as a barrier, preventing moisture and oxygen from reaching the steel surface and causing rust.

- Q: Can steel sheets be used in the electronics industry?

- Yes, steel sheets can be used in the electronics industry. While electronic devices are typically made with materials such as plastic and aluminum, steel sheets can still play a role in the manufacturing process. Steel sheets are commonly used to create structural components, enclosures, brackets, and other parts in electronic devices. They provide strength, durability, and protection for delicate electronic components. Steel sheets are also used for shielding purposes to prevent electromagnetic interference (EMI) in electronic equipment. Overall, steel sheets have several applications in the electronics industry, making them a viable material choice for certain components and enclosures.

- Q: What is the typical impact strength of a steel sheet?

- The typical impact strength of a steel sheet can vary depending on the grade and thickness of the steel. However, steel sheets generally have high impact strength due to their tough and durable nature.

- Q: Are the steel sheets available in different grades?

- Different grades of steel sheets are available. Steel is categorized into various grades depending on its composition, strength, and other properties. These grades encompass carbon steel, stainless steel, alloy steel, and tool steel, among others. Each grade possesses distinct characteristics and is appropriate for different applications. The selection of a grade relies on factors such as the desired strength, resistance to corrosion, and cost-effectiveness for the particular use. Consequently, when buying steel sheets, it is crucial to take into account the grade that most effectively meets the intended purpose.

- Q: What's the best way to open a 10mm thick steel sheet?

- Plate is one of the four major steel products (plate, tube, mould, silk). In developed countries, steel plate production accounts for more than 50% of the total steel production. With the development of China's national economy, steel plate production has gradually increased.

- Q: How do steel sheets handle chemical exposure?

- Steel sheets are renowned for their outstanding ability to resist chemical exposure. They exhibit a high level of resistance to corrosion and can endure exposure to a wide array of chemicals, including acids, alkalis, solvents, and other substances that cause corrosion. This exceptional resistance is primarily attributed to the formation of a protective oxide layer, known as patina, on the surface of the steel. This layer acts as a barrier, preventing the chemicals from attacking the steel. Moreover, steel sheets can be further safeguarded by applying various protective coatings, such as galvanization, epoxy coatings, or powder coatings. These coatings provide an extra layer of protection and enhance the steel's resistance to chemical exposure. However, it is important to acknowledge that the resistance of steel sheets to chemical exposure may vary based on the specific type and concentration of the chemicals involved. Highly concentrated or aggressive chemicals may still lead to some degree of corrosion or damage to the steel surface over time. Hence, it is crucial to carefully consider the specific chemical environment and select the appropriate grade of steel and protective coating to ensure optimum resistance to chemical exposure. In summary, steel sheets are a dependable and durable choice for applications that demand resistance to chemical exposure. With careful selection and maintenance, they can effectively withstand diverse chemical environments and deliver long-lasting performance.

- Q: Are steel sheets suitable for electrical applications?

- Yes, steel sheets can be suitable for electrical applications. They have good electrical conductivity and can be used for applications such as electrical enclosures, panels, and grounding components. However, it is important to consider factors like insulation and corrosion resistance when using steel sheets in electrical applications.

- Q: Can steel sheets be rolled into cylinders or tubes?

- Yes, steel sheets can be rolled into cylinders or tubes through a process called roll forming.

- Q: How do steel sheets perform in terms of scratch resistance?

- Steel sheets are known for their exceptional scratch resistance. Due to their strong and durable nature, steel sheets are highly resistant to scratches and abrasions. This makes them ideal for various applications where the material may come into contact with potentially damaging objects or surfaces. Steel sheets can withstand normal wear and tear, making them suitable for heavy-duty and high-traffic environments. Additionally, steel sheets can be further enhanced with coatings or finishes to provide an even higher level of scratch resistance. Overall, steel sheets are renowned for their excellent scratch resistance, making them a reliable choice for many industrial and commercial applications.

- Q: Can steel sheets be used for cladding or facade systems?

- Yes, steel sheets can be used for cladding or facade systems. Steel sheets offer durability, strength, and versatility, making them suitable for various architectural applications. They can be used to create visually appealing and modern facades while providing protection against weather elements and enhancing energy efficiency.

Send your message to us

Galvanized Corrugated Steel Coil in High Quality

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 100 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords