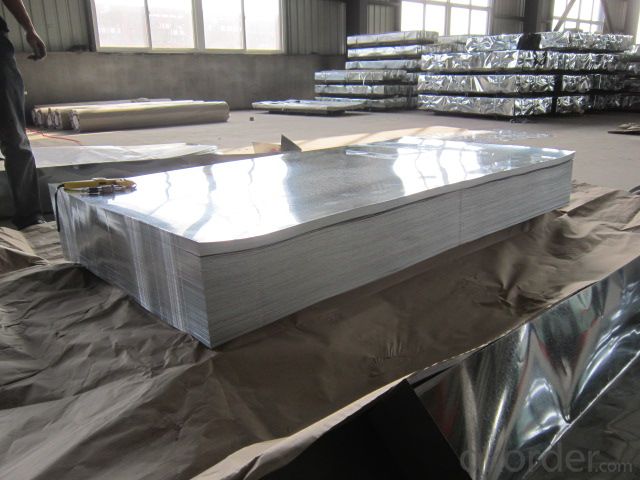

Hot-dip Galvanized Steel Sheet GI Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Hot-dip Galvanized Steel Sheet

Description:

The most external layer is all zinc, but successive layers are a mixture of zinc and iron, with an interior of pure steel. These multiple layers are responsible for the amazing property of the metal to withstand corrosion-inducing circumstances. Zinc also protects the steel by acting as a "sacrificial layer." If rust does take hold on the surface of Galvanized Steel Coil, the zinc will get corroded first. This allows the zinc that is spread over the breach or scratch to prevent rust from reaching the steel.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

1. Good Resistance to Corrosion

2. Qualified Processing Machinability

3. High Thermal Resistance

4. Excellent Reflectivity

5. Inexpensive and effective enough

6. Can be recycled and reused multiple times

Application:

With excellent cold bending molded manufacturablity, good decoration effect, strong anti-corrosion ability, galvanized steel coils and sheets are also pollution-free and easily recycled. Accordingly, they can be used as final products and basic plates of color coated steel coils and widely applied in construction, home appliances, decoration, ect.

Construction, packaging, railway vehicles, agricultural machinery and daily life.

Oiled/dry, Skin-pass/Nonskin-pass, Regular/Minimize/Zero Spangle

For countless outdoor, marine, or industrial applications, Galvanized Steel Coil is an essential fabrication component.

Architecture Roofs and outside walls of civilian and industrial buildings, garage doors, fencings and window blinds.

Appliances Industry Outer clad sheets for washing machine, refrigerator, television, air conditioner and ventilation system, explosion-proof strip, solar water heater and appliance parts.

Auto Industry Muffler, heat shields of exhaust pipe and catalytic converter, auto parts & accessories under the frame, signboard in highway

Industrial Instruments Electric control cabinet, industrial refrigeration equipment, automatic vending machine

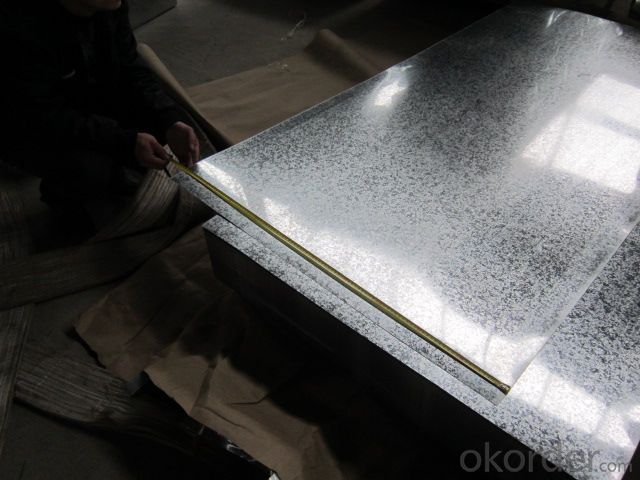

Product Specification:

Base sheet : galvanized steel sheet, pre painted galvanized steel sheet

Zinc:40G-275G

Thickness:0.12mm-3.2mm

Width:600mm-1500mm

Length:1000mm-11800mm or as request

Package:Standard seaworthy export packing: 3 layers of packing, inside is kraft paper,water plastic film is in the middle and outside GI steel sheet to be covered by steel strips with lock.

FAQ:

1.How many pieces for one ton of the Hot-dip Galvanized Steel Sheet?

The pieces for one tone is decided by the thickness of the sheet, but we can make it according to your requirements in the reasonable range.

2. Do you have pallets for the package?

Yes, we must use pallets for the package in order to load.

3. How many tons do you load in one 20’FCL?

Usually we can load 26tons in one 20’FCL container.

- Q: What is the difference between a black and pickled steel sheet?

- The main difference between a black steel sheet and a pickled steel sheet lies in the surface finish and the process they undergo. A black steel sheet, also known as hot-rolled steel, is produced through a process called hot rolling. During this process, the steel is heated above its recrystallization temperature and passed through rollers to achieve the desired thickness. The resulting sheet has a dark, rough, and scaly surface, hence the term "black steel." The black surface is a result of the oxidation that occurs during the hot rolling process. On the other hand, a pickled steel sheet is produced through a process called pickling. After hot rolling, the black steel sheet undergoes a treatment where it is immersed in an acidic solution, typically hydrochloric acid or sulfuric acid. This pickling process removes the oxide scale from the surface of the black steel sheet, resulting in a smooth and clean surface. The pickling process also helps to improve the steel's corrosion resistance. The choice between a black steel sheet and a pickled steel sheet depends on the intended application. Black steel sheets are often preferred for structural components, such as beams and columns, where surface appearance is not a critical factor. Pickled steel sheets, with their smooth and clean surface, are commonly used in applications where a high-quality finish is required, such as automotive panels, appliances, and architectural elements. In summary, the key difference between a black steel sheet and a pickled steel sheet is the surface finish. The black steel sheet has a rough and scaly surface due to oxidation during hot rolling, while the pickled steel sheet has a smooth and clean surface after undergoing a pickling process to remove the oxide scale.

- Q: Can the steel sheets be used as a magnetic surface?

- Indeed, the use of steel sheets as a magnetic surface is possible. Steel, being a ferromagnetic material, possesses the ability to be magnetized and maintain its magnetism even when the magnet is no longer present. This characteristic enables steel sheets to attract and secure magnetic items. In numerous scenarios, steel sheets are widely employed as magnetic surfaces, including magnetic boards, magnetic whiteboards, and magnetic organizers. By employing magnets, it becomes effortless to affix notes, documents, and additional magnetic objects onto steel sheets, rendering them a practical and adaptable means of organization and exhibition.

- Q: Can steel sheets be used for clamps or fasteners?

- No, steel sheets themselves cannot be used directly as clamps or fasteners. However, steel sheets can be used to manufacture clamps or fasteners. Steel sheets can be cut, shaped, and manipulated to create various types of clamps and fasteners such as brackets, plates, or strips. These manufactured components can then be used as clamps or fasteners in different applications, providing strength, durability, and secure attachment. So while steel sheets themselves cannot function as clamps or fasteners, they can be transformed into the necessary components to serve these purposes.

- Q: What is the typical price range for steel sheets?

- The typical price range for steel sheets can vary depending on several factors such as the type and grade of steel, the thickness and size of the sheets, and the current market conditions. Generally, steel sheets can range in price from around $30 to $200 per sheet. However, it's important to note that these prices are approximate and can fluctuate significantly. It is always recommended to check with local suppliers or manufacturers to get the most accurate and up-to-date pricing information for steel sheets.

- Q: What is the average lifespan of a steel sheet roof?

- The average lifespan of a steel sheet roof can vary depending on various factors such as the quality of the steel, installation techniques, climate conditions, and maintenance. However, a well-maintained steel sheet roof can typically last between 30 to 50 years or even longer.

- Q: Can steel sheets be used for agricultural fencing or enclosures?

- Yes, steel sheets can be used for agricultural fencing or enclosures. Steel sheets are highly durable and provide excellent strength, making them suitable for securing livestock and protecting crops. They can be formed into panels or rolls, allowing for easy installation and customization to fit different fencing or enclosure needs. Additionally, steel sheets are resistant to weathering, corrosion, and pests, ensuring long-lasting performance in agricultural environments. Overall, steel sheets are a reliable and effective choice for agricultural fencing or enclosures.

- Q: Are steel sheets suitable for outdoor furniture?

- Yes, steel sheets are suitable for outdoor furniture. Steel is known for its durability and resistance to weather elements such as rain, sunlight, and temperature fluctuations. It can withstand outdoor conditions without rusting or deteriorating easily, making it a suitable choice for outdoor furniture.

- Q: Can the steel sheets be easily formed into curves or angles?

- Yes, steel sheets can be easily formed into curves or angles through a process known as sheet metal bending. This involves using specialized tools such as brakes or press machines to bend the steel sheets to the desired shape. The ability to form curves or angles largely depends on the thickness and type of steel being used. Thinner and more malleable steel sheets are generally easier to work with and can be formed into tighter curves or angles. However, thicker and less malleable steel sheets may require more force and advanced machinery to achieve the desired shape.

- Q: Are steel sheets suitable for railway infrastructure?

- Yes, steel sheets are suitable for railway infrastructure. Steel is a widely used material in the construction of railway infrastructure due to its strength, durability, and versatility. One of the main advantages of using steel sheets for railway infrastructure is their high strength-to-weight ratio. Steel is known for its exceptional strength, allowing it to withstand heavy loads and provide long-lasting support to railway tracks, bridges, and other structures. This strength is crucial in ensuring the safety and stability of the railway system, especially when dealing with the immense weight and impact forces exerted by trains. Additionally, steel sheets offer excellent durability and resistance to wear and tear. Railway infrastructure is subjected to constant stress, including vibrations, impacts, and extreme weather conditions. Steel's inherent properties make it highly resilient to these factors, minimizing the need for frequent repairs and maintenance. This durability translates into significant cost savings in the long run, as steel structures have a longer lifespan compared to other materials. Moreover, steel sheets are highly versatile and can be easily fabricated into various shapes and sizes to meet specific railway infrastructure requirements. This flexibility allows for the efficient construction of rails, sleepers, bridges, and other components needed for a functional and safe railway system. Steel's adaptability also enables easy modifications and expansions to the infrastructure as needed, ensuring compatibility with evolving transportation needs. In conclusion, steel sheets are well-suited for railway infrastructure due to their strength, durability, and versatility. Their high strength-to-weight ratio, resistance to wear and tear, and ease of fabrication make them an ideal choice for constructing and maintaining railway tracks, bridges, and other structures. The use of steel in railway infrastructure ensures the safety, efficiency, and longevity of the railway system.

- Q: Are steel sheets suitable for architectural cladding?

- Yes, steel sheets are suitable for architectural cladding. Steel cladding offers durability, strength, and versatility in design, making it a popular choice for architects. It can be easily formed into different shapes and sizes, providing flexibility in creating unique building facades. Additionally, steel cladding is resistant to weather conditions, fire, and pests, making it a long-lasting and low-maintenance option for architectural applications.

Send your message to us

Hot-dip Galvanized Steel Sheet GI Sheet

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 50 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords