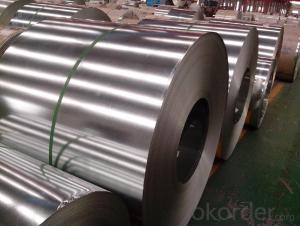

Galvanized Sheet Coil/GI Sheet/galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time by bulk or container

deformed steel bar grade 40

material: HRB400, BS4449 GR460B

size: 8-36mmx12m.

short delivery time with bulk or container

packing: Mill standard export packing in bundles/coil, around 2tons/bundle.

country of Origin: China

delivery Time: Within a 35 days

Shipment: by bulk vessel or by container

Leading goods:

section steel:angles,channels,I-beam,H-beam;

coils:cold/hot rolled coils,PPGI,galvanized coils,plate,checkered plate,cutting steel plate,steel strip;

wire rod:steel wire,deformed wire,bar;

pipe:seamless pipe,rectangular pipe,welded pipe,spiral welded pipe,pipe fittings;

stainless steel:steel sheets,stainless steel strips,stainless bar,stainless tube;

special:weathering steel,shipbuilding steel;

construction steel:C-channel,Z-channel,T-bar,high-speed divider plate,corrugated steel plate,steel grating.

Advantage:

We are the spot supplier, Six huge warehouses which can hold 20,000 MT goods.

It makes the cost lower than others,we can provide the competitive price for you.

Delivery time:

Normal sizes can be provided in 7days, the others should be ready in 30---45 days.

Further treatment:

We can offer cutting,painting,drilling holes,bending,threading, welding,galvanization,packing etc.

Security interest:

We have already passed the ISO9001, BV and SGS authentication which makes the quality secured.

If you have the interest in any of the products we can provided, pls don't hesitate to connect with me. Looking forward to cooperate with you.

FAQ of Steel Deformed Bar

1. More than 10 years experience in this industry

2. 100,000 tons exporting per month

3. Professional foreign trade tea

4. OEM&ODM capacity

5. High quality assured & competitive price

6. Try our best to meet your needs & save your budget

7. Very popular in Southeast Asia, Africa, Mid-East and South America etc.

8. VIP membership system, first time customers and long-term cooperation customers can get extra discount on some products.

Cold-rolled stainless steel sheet hot-rolled coil is crude and rolled under low temperature conditions. Because there will be no high-temperature processing, for this procedure in the production process, so people often referred to as its cold-rolled steel. Higher than the hardness of cold-rolled steel hot-rolled, cold-rolled stainless steel sheet so the texture is hard, not suitable for a large number of deep-processing.

In accordance with the organizational characteristics of steel

In accordance with the organizational characteristics of stainless steel sheet to divide, then we would more complicated than in accordance with the production process to divide. But they can be roughly divided into five categories, namely: austenitic sheet, plate ferritic, austenitic - ferritic sheet, plate martensitic precipitation hardening stainless steel sheet plate these five categories. Here we will highlight five categories of stainless steel sheet own characteristics.

Austenitic stainless steel sheet contains chromium, a small amount of molybdenum, titanium, nickel and other elements, so that the hardness and plasticity are high, life is widely used.

The amount of chromium-containing ferritic stainless steel sheet is about twice as austenitic. Thus, the ferritic stainless steel sheet hardness, corrosion resistance, anti-oxidation properties better than austenitic stainless steel sheet, but its disadvantage is poor machinability, commonly used as some special parts production.

Austenitic - ferritic stainless steel sheet is compatible with austenitic - ferritic stainless steel plate advantages, a variety of performances are relatively good, and life applications are particularly widespread.

- Q: How do steel sheets perform in abrasive environments?

- Steel sheets perform well in abrasive environments due to their high hardness and durability. They are able to resist wear and tear caused by abrasive particles, ensuring long-term performance and protection. The smooth surface of steel sheets also minimizes friction, reducing the chances of damage and maintaining their structural integrity even in harsh conditions.

- Q: Can steel sheets be used for making furniture?

- Yes, steel sheets can be used for making furniture. Steel is a durable and sturdy material that can be shaped and formed into various furniture designs. It is often used for making chairs, tables, shelves, and other industrial or modern furniture pieces.

- Q: Are steel sheets suitable for interior wall cladding?

- Yes, steel sheets are suitable for interior wall cladding. They provide a durable and modern aesthetic, are resistant to moisture and fire, and can be customized to fit various design styles.

- Q: Are steel sheets resistant to warping or bending?

- Yes, steel sheets are known for their high resistance to warping or bending due to their strong and rigid nature.

- Q: What are the common thicknesses for hot-rolled steel sheets?

- The common thicknesses for hot-rolled steel sheets range from 1.5mm to 20mm, with popular options including 3mm, 6mm, 8mm, and 10mm.

- Q: What is the average yield strength of steel sheets?

- The average yield strength of steel sheets can vary depending on the specific grade and thickness of the steel being used. However, as a general range, the average yield strength of steel sheets typically falls between 250 and 600 megapascals (MPa). It is important to note that different steel grades, such as mild steel, high-strength low-alloy (HSLA) steel, or stainless steel, will have different average yield strengths. Additionally, the thickness of the steel sheet can also impact its yield strength, with thinner sheets generally having higher yield strengths. Therefore, it is crucial to consult the specifications and standards provided by the manufacturer or industry guidelines to determine the specific average yield strength for a particular steel sheet.

- Q: Can steel sheets be used for sculptures and artwork?

- Yes, steel sheets can definitely be used for sculptures and artwork. Steel is a versatile material that can be shaped, welded, and manipulated into various forms and designs. Its strength and durability make it ideal for creating large outdoor sculptures or intricate indoor artwork. Additionally, steel sheets can be painted, textured, or treated to achieve different visual effects, allowing artists to explore different creative possibilities.

- Q: How do steel sheets perform in terms of corrosion resistance?

- Steel sheets possess good corrosion resistance in general, particularly when they are coated with protective layers like zinc or alloys. The corrosion resistance of steel sheets relies on the steel's composition and quality, as well as the environment in which they are employed. Stainless steel sheets, for instance, demonstrate remarkable resistance against corrosion due to the presence of chromium and other alloying elements. These sheets prove highly effective in environments with elevated humidity, exposure to saltwater, or acidic conditions. However, in aggressive environments, uncoated or low-alloy steel sheets may be vulnerable to rust and corrosion. Regular maintenance, such as the application of protective coatings or the use of corrosion inhibitors, can enhance the corrosion resistance of steel sheets and extend their lifespan.

- Q: How thick are steel sheets available?

- A wide variety of thicknesses can be found for steel sheets, catering to the specific needs of each application. Steel sheets commonly come in thicknesses ranging from 0.5mm (or 0.020 inches) up to several inches. Gauge is typically used to measure the thickness of steel sheets, with lower gauge numbers indicating thicker sheets. Nevertheless, it's worth mentioning that the availability of steel sheets in particular thicknesses might differ depending on the supplier and the type of steel employed.

- Q: Are steel sheets resistant to impact?

- Yes, steel sheets are generally resistant to impact due to their high strength and durability.

Send your message to us

Galvanized Sheet Coil/GI Sheet/galvanized Steel Sheet

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 500 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords