Galvanized Tube Steel

Galvanized Tube Steel Related Searches

Galvanized Steel Tube Galvanized Steel Tub Steel Galvanized Galvanized Stainless Steel Galvanized Steel Piping Galvanized Steel Pipes Galvanized Steel Tank Galvanized Steel Tubs Galvanized Corrugated Steel Weld Galvanized Steel Galvanized Steel Square Tubing Galvanised Scaffold Tube Painted Galvanized Steel Corrugated Galvanized Steel Galvanized Steel Beams Galvanized Steel Panel Rusted Galvanized Steel Galvanized Steel Culvert Pipe Rusting Galvanized Steel Galvanized Steel Grating Galvanized Steel Shed Galvanized Steel Panels Powder Coating Galvanized Steel Galvanized Steel Post Galvanized Steel Stock Tank Galvanized Steel Roof Hot Dipped Galvanized Steel Galvanized Steel Paint Galvanized Steel Siding Galvanized Steel PoolGalvanized Tube Steel Supplier & Manufacturer from China

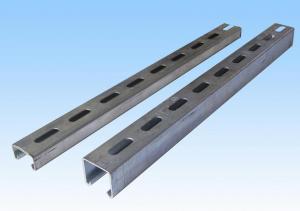

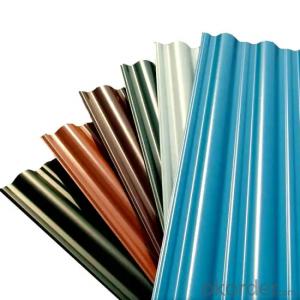

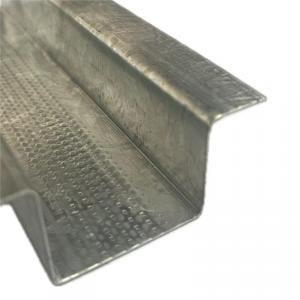

Galvanized Tube Steel is a type of steel product that has been coated with a layer of zinc to provide corrosion resistance and enhance its durability. This process of galvanization not only protects the steel from rust and other forms of degradation but also gives it an aesthetically pleasing finish. The product is widely recognized for its strength and versatility, making it a popular choice for various industries and construction projects.Galvanized Tube Steel finds its application in a diverse range of usage scenarios, such as in the construction of buildings and infrastructure, automotive manufacturing, and the creation of agricultural equipment. Its resistance to corrosion and ability to withstand harsh weather conditions make it an ideal material for outdoor applications, including fencing, scaffolding, and structural support systems. Additionally, its smooth and shiny appearance makes it suitable for applications where aesthetics are a consideration, such as in the production of furniture and decorative items.

Okorder.com is a reputable wholesale supplier of Galvanized Tube Steel, boasting a large inventory that caters to the needs of various industries. With a commitment to quality and customer satisfaction, Okorder.com ensures that the products they offer meet the highest standards. Their extensive range of Galvanized Tube Steel products makes them a one-stop-shop for businesses looking to source this versatile and durable material for their projects.

Hot Products