Galvanized Steel Piping

Galvanized Steel Piping Related Searches

Galvanized Steel Pipes Galvanized Steel Tube Galvanized Tube Steel Galvanized Steel Culvert Pipe Galvanized Steel Square Tubing Steel Galvanized Galvanized Steel Grating Non Galvanized Steel Pipe Galvanized Stainless Steel Galvanized Steel Tubs Galvanized Steel Tub Galvanized Steel Beams Galvanized Steel Tank Galvanized Steel Panels Galvanized Steel Fencing Stainless Steel Piping Galvanized Corrugated Steel Galvanized Steel Siding Galvanized Steel Panel Galvanized Steel Edging Galvanized Steel Roof Painted Galvanized Steel Powder Coating Galvanized Steel Rusting Galvanized Steel Galvanised Ducting Weld Galvanized Steel Galvanized Steel Pool Galvanized Steel Roofing Panels Rusted Galvanized Steel Hot Dipped Galvanized SteelGalvanized Steel Piping Supplier & Manufacturer from China

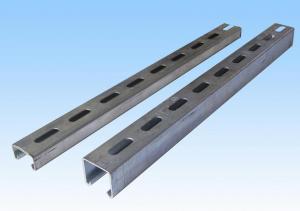

Galvanized Steel Piping is a type of steel pipe that has undergone a galvanization process, which involves coating the steel with a layer of zinc to protect it from corrosion and rust. This process significantly enhances the durability and lifespan of the pipe, making it a popular choice for various construction and industrial applications. The product is known for its strength, flexibility, and resistance to harsh environmental conditions, making it suitable for a wide range of uses.Galvanized Steel Piping finds its application in numerous scenarios, such as water supply systems, gas pipelines, construction projects, and industrial facilities. Its corrosion-resistant properties make it an ideal choice for outdoor applications where the pipe may be exposed to moisture and other elements. Additionally, it is widely used in agricultural irrigation systems, as its durability ensures long-lasting performance even under harsh weather conditions. The versatility of galvanized steel piping makes it a popular choice for both commercial and residential projects.

Okorder.com is a reputable wholesale supplier of Galvanized Steel Piping, offering a vast inventory of high-quality products to cater to the needs of various industries. With a commitment to providing excellent customer service and competitive pricing, Okorder.com has established itself as a reliable source for businesses looking to purchase this essential product in bulk. By partnering with Okorder.com, customers can rest assured that they are receiving top-quality galvanized steel piping at the best possible prices.

Hot Products